Scrap collecting workbench with discharging holes

A blanking hole and worktable technology, applied in the field of parts processing, can solve the problems of waste accumulation and easy accumulation of waste, and achieve the effect of avoiding accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

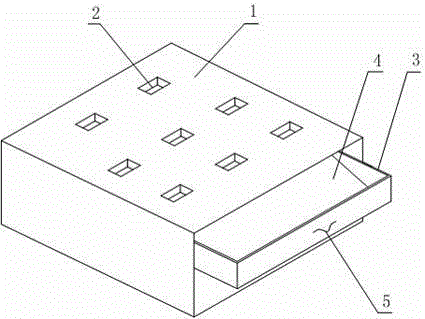

[0018] Such as figure 1 Shown is a waste collection workbench with a drop hole, a waste collection workbench with a drop hole, including a table body 1 for installing a fixture and a power head, and the table body 1 is internally provided with The drawer 3 pulled away from the side of the table body 1, the bottom surface of the drawer 3 is provided with a guide plate 4 inclined downward from the inside to the outside, and the upper surface of the table body 1 is provided with a number of blanking holes 2, the blanking holes 2 communicates with the inside of the drawer 3, and the drawer 3 is provided with a handle 5. In the use of this embodiment, the drawer 3 is pushed to the inside of the table body 1, and the normal processing work is carried out after placing the fixture and the power head on the table body 1, and the waste chips generated in the process are removed. Fall onto the table body 1, and fall into the drawer 3 inside the table body 1 through the blanking hole 2....

Embodiment 2

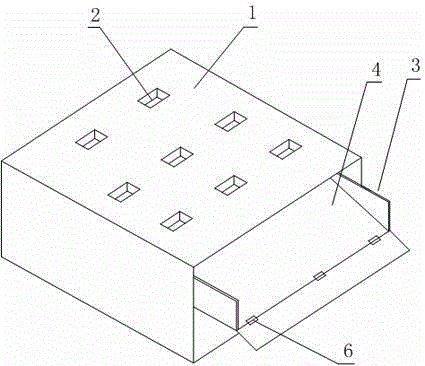

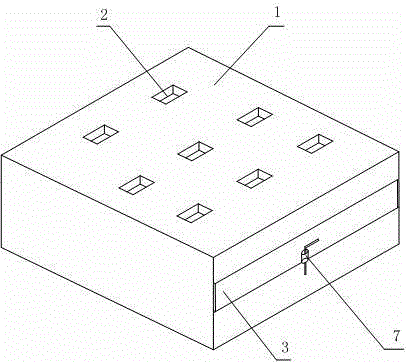

[0020] Such as figure 2 and image 3 Shown is a waste collection workbench with a drop hole, on the basis of Embodiment 1, the outward side of the drawer 3 is connected to its bottom surface through a hinge 6; the outward side of the drawer 3 is connected through a latch 7 is connected with the side of table body 1. Conventionally, the waste chips collected in the drawer 3 can only be dumped after the drawer 3 is taken out after the processing is completed or the work is stopped. However, in this embodiment, the user can artificially release the fixation of the latch 7, and through the hinge 6, the outer surface of the drawer 3 becomes an opening, so that waste can be directly discharged, and during the processing It is also possible to discharge waste at the same time, which is convenient for use; when it is not necessary to discharge waste in time, this embodiment can also ensure the integrity of the four sides of the drawer through the latch 7 to ensure its storage capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com