High-strength insulation material

An insulating material, high-strength technology, used in electronic equipment, applications, household appliances, etc., can solve the problems of puncturing high-strength insulating materials, not overloading, easy to be ignited, etc., to achieve material environmental protection, high insulation performance, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1

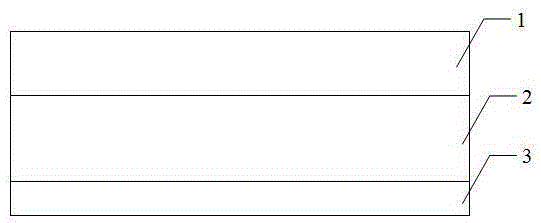

[0020] High-strength insulation material, including PTT fiber base layer 1, insulation layer 2, and insulation layer 3. Insulation layer 2 includes the following raw materials by weight: 30kg polyolefin, 15kg silicone crosslinking agent, 15kg silicon dioxide, 11kg hydroxide Silicon, 10kg magnesium hydroxide, 6kg iron oxide, 5kg barium sulfate, 5kg magnesium silicate, 3kg talc powder, 3kg lubricant, 4kg antioxidant, 2kg compatibilizer and 1kg organic silicon leveling agent, insulation layer 3 is Fiberglass layer. Among them, the antioxidant is antioxidant 3114. The compatibilizer is ST-1 compatibilizer. The lubricant is paraffin wax. The thickness ratio of the PTT fiber base layer 1, the insulation layer 2 and the insulation layer 3 is 2:4:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap