Automatic hydrogen supply integrated control system

An integrated control system and automatic supply technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of equipment overcapacity, increase of electricity and other input costs, changes in hydrogen pressure and flow, etc., to ensure supply pressure and flow, Efficient use of production capacity and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

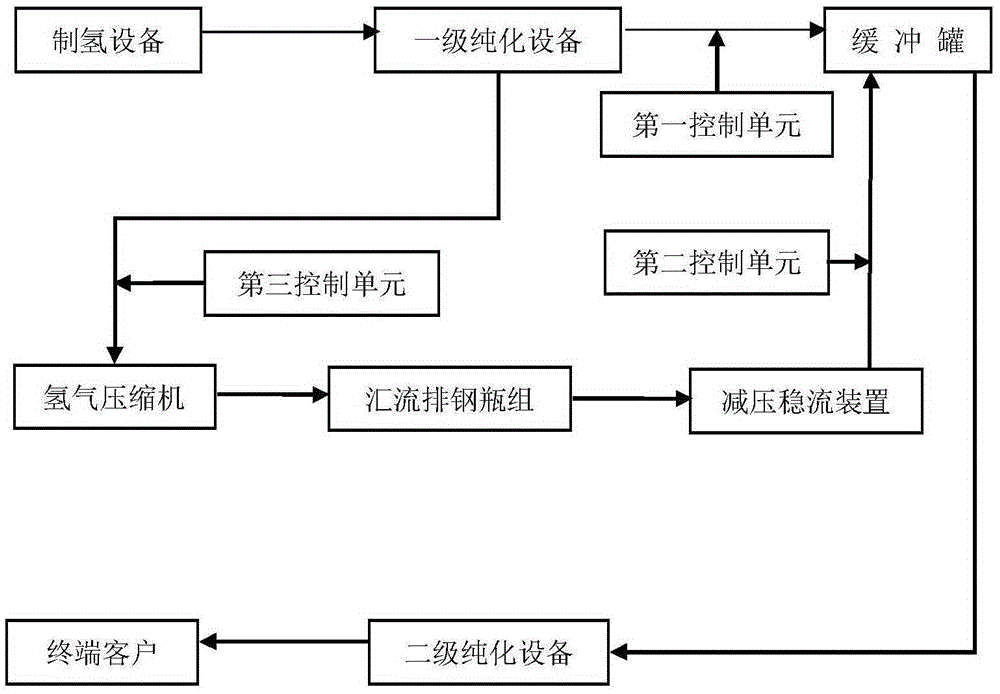

[0013] Such as figure 1 As shown, an integrated control system for automatic hydrogen supply, including hydrogen production equipment, primary purification equipment, buffer tank, secondary purification equipment, hydrogen compressor, busbar steel cylinder group, decompression and steady flow device and hydrogen pressure control system, The hydrogen production equipment in this embodiment is a water electrolyzer.

[0014] The hydrogen production equipment is connected to the primary purification equipment, the primary purification equipment is also connected to the buffer tank and the hydrogen compressor respectively, the buffer tank is also connected to the secondary purification equipment, the hydrogen compressor is connected to the bus cylinder group, and the bus cylinder group is connected to the decompression The flow stabilization device, the decompression and flow stabilization device is connected to the buffer tank.

[0015] The hydrogen pressure control system includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com