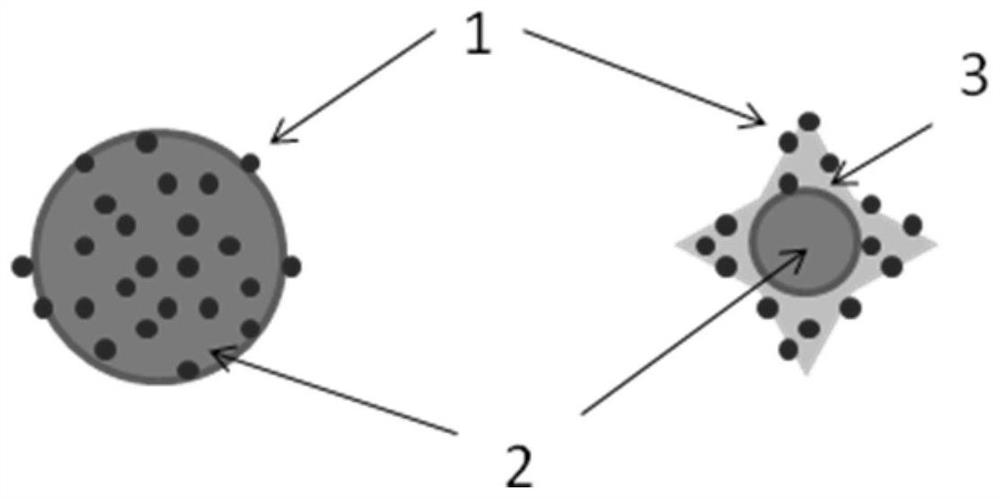

Negative oxygen ion polyester fiber with four-leaf-shaped skin-core structure and preparation method thereof

A technology of negative oxygen ion fiber and skin-core structure, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc. Reduce problems such as reducing melting point and rheological properties, simplifying the skin-core spinning process, and reducing production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

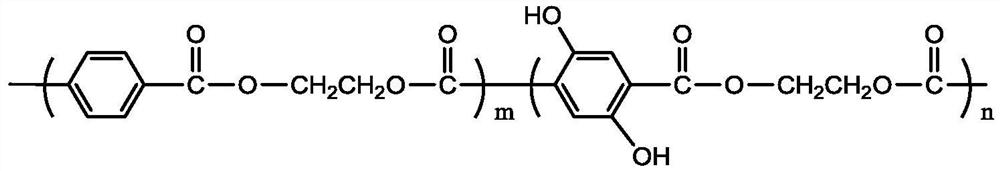

Embodiment 1

[0054] 116.2 kilograms of terephthalic acid (700 moles), 59.4 kilograms of 2,5-dihydroxyterephthalic acid (300 moles), 62 kilograms of ethylene glycol (1000 moles), 83 grams of catalyst antimony trioxide, Put 830 grams of matting agent titanium dioxide and 8 kilograms of tourmaline powder (average pore size 120nm) into the polymerization reactor, first heat up to 100°C under normal pressure and stir for 1 hour, then continue to heat up to 250°C to react and vacuumize, observe the water outlet situation, 4 After one hour, the esterification rate reached 91%. Continue to maintain a high vacuum and raise the temperature to 290°C for 5 hours to react. When the melt viscosity reaches 0.51, the reaction is terminated, cooled and cut into pellets, and the modified polyester masterbatch, namely 2,5-di Hydroxyethylene terephthalate-ethylene terephthalate copolymer polyester masterbatch. In the copolyester, the mole fraction m:n of ethylene terephthalate:2,5-dihydroxyethylene terephthal...

Embodiment 2

[0059] The relative addition amount of 2,5-dihydroxyterephthalic acid and terephthalic acid in Example 1 was changed, and the other operating steps were the same as in Example 1. The quantities of reactants are: 99.6 kg of terephthalic acid (600 moles), 79.2 kg of 2,5-dihydroxyterephthalic acid (300 moles), 62 kg of ethylene glycol (1000 moles), 83 grams of catalyst Antimony trioxide, 830 grams of matting agent titanium dioxide, 12 kilograms of tourmaline powder (average pore size 120nm).

[0060] The four-leaf sheath-core structure anion composite fiber obtained by spinning has an anion release capacity of 6000 / cm 3 .

Embodiment 3

[0062] The 2,5-dihydroxyterephthalic acid in Example 1 was changed to 2-hydroxyterephthalic acid, and the amount of reactants was changed accordingly. The quantities of reactants are: 116.2 kg of terephthalic acid (700 moles), 54.6 kg of 2,5-dihydroxyterephthalic acid (300 moles), 62 kg of ethylene glycol (1000 moles), 83 grams of catalyst Antimony trioxide, 830 grams of matting agent titanium dioxide, 8 kilograms of tourmaline powder (average pore size 120nm). Put the above materials into the polymerization reactor, first raise the temperature to 100°C under normal pressure and stir for 1 hour, then continue to raise the temperature to 250°C to react and vacuumize, observe the water outlet, when the esterification rate reaches 96%, continue to maintain high vacuum And raise the temperature to 285 ℃ for 5 hours, after the melt viscosity reaches 0.54, stop the reaction, cool and cut into pellets, and obtain the modified polyester copolymer masterbatch, that is, 2-hydroxyethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com