Anti-floating device suitable for glass fiber reinforced plastic integrated pumping station

A technology that integrates pumping stations and glass fiber reinforced plastics. It is used in pumping stations, protection devices, water supply devices, etc., which can solve problems such as corrosion caused by long-term use, and achieve the effect of reducing workload, ensuring normal work, and increasing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

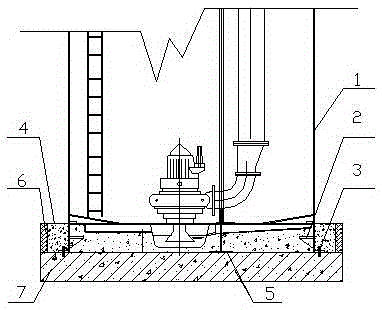

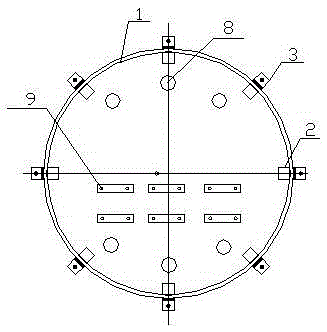

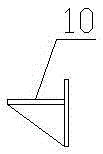

[0026] The manufacture and use of the anti-floating device is to connect the inner and outer metal anti-floating devices on the glass fiber reinforced plastic base plate with the reinforced concrete bottom plate under the glass fiber reinforced plastic base, and cooperate with the concrete poured on site twice to make the metal anti-floating device, glass fiber reinforced plastic anti-floating device, reinforced concrete The base plate and the secondary cast-in-place concrete are integrated to ensure that the gravity of the pumping station plus the concrete is greater than the buoyancy of the water, avoiding the pumping station from floating.

[0027] The specific implementation process is shown in the attached figure of the manual:

[0028] Firstly, the structural form of the anti-floating base is determined according to the model of the water pump, and then the basin bottom mold is made, the FRP bottom basin is made, and the FRP bottom basin is assembled with the pump station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com