Wedge-shaped base leveling device

A wedge-shaped, base-level technology, applied in the direction of architecture and building structure, can solve the problems of polluting the construction site environment, affecting construction efficiency, affecting leveling quality, etc., and achieve the effects of improving the construction environment, controlling decoration costs, and reducing construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

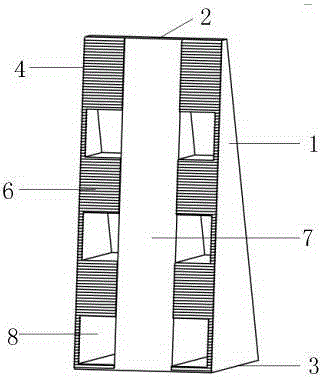

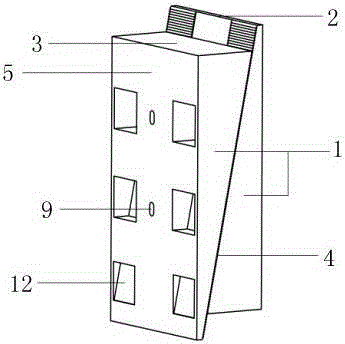

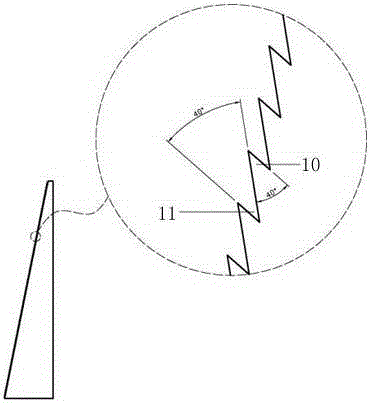

[0017] Such as figure 1 , figure 2 As shown, a wedge-shaped base leveling device of the present invention is composed of two wedge-shaped leveling parts connected by buckles. The structures of the two wedge-shaped leveling parts are exactly the same. The upper bottom surface 2 and the lower bottom surface 3 of the part are rectangles with the same length and different widths, the upper part is small and the lower part is large, the front side is the slope 4 of the leveling part, and the back side corresponding to the slope 4 is a smooth rectangular surface 5; the vertical side of the slope 4 Divided into three parts, the two sides are serrated slopes 6 with the same width, the middle is a smooth slope 7, and the sawtooth slopes 6 on both sides of the slope 4 have three first wedge-shaped slots 8 distributed at equal intervals; There are also three second wedge-shaped slots 12 equally spaced on both sides of the rectangular surface 5 .

[0018] In this invention, the base-le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com