Small-hole high-frequency noise eliminator

A muffler and high-frequency technology, applied in the field of small-hole high-frequency mufflers, can solve the problem of limited noise reduction effect, and achieve the effect of improving the effect, reducing the noise, and improving the effect of eliminating noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

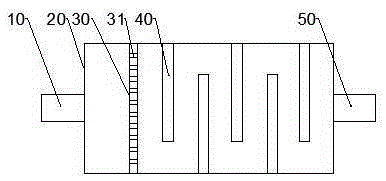

[0018] Such as figure 1 As shown, the small-hole high-frequency muffler has a scheme of: comprising a housing 20, one end of the housing 20 is connected to the intake pipe 10, the other end of the housing 20 is connected to the outlet pipe 50, and the housing 20 is provided with a vertical partition 30. The plate 30 divides the inside of the housing 20 into two chambers, left and right. Small holes 31 are uniformly arranged on the partition 30. The total area of the small holes 31 is larger than the cross-sectional area of the intake pipe 10. A deflector 40 is arranged in the right chamber. , the deflectors 40 are radially staggered in the right chamber to form an S-shaped flow channel in the right chamber, and the deflectors 40 are provided with a sound-absorbing layer.

[0019] In addition, in this embodiment, the shell 20 is provided with sound-absorbing materials. The advantage is that the effect of noise reduction is further improved. The sound-absorbing material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com