Rotary blind rivet

A blind rivet and rotary technology, applied in the direction of rivets, etc., can solve the problems of increasing processing cost and assembly cost, axial force deviation, unstable installation, etc. The effect of loosening performance and reliability in use, saving processing costs and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

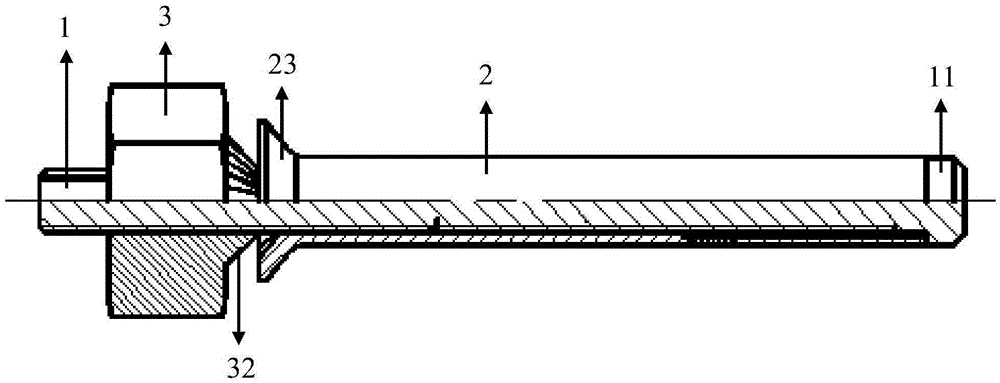

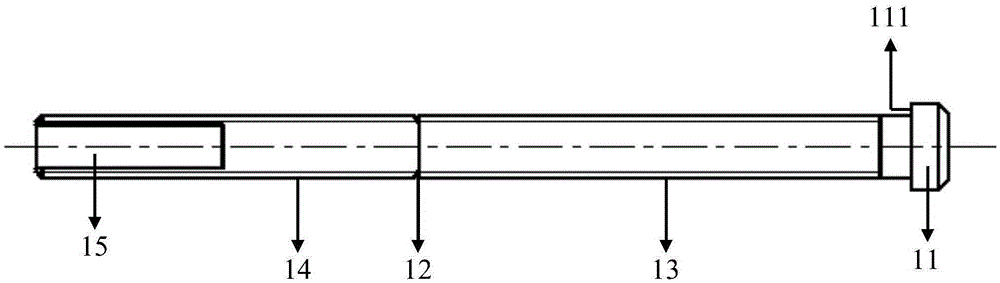

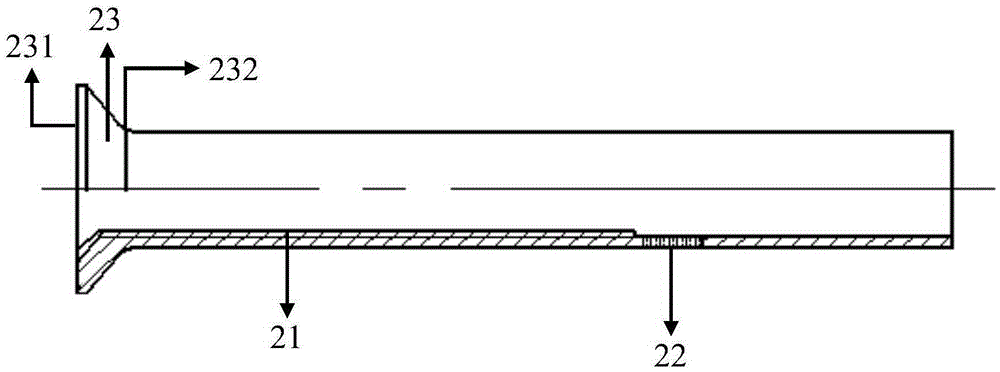

[0020] The present invention creates an embodiment of the structure such as Figure 1-4 As shown, it includes a core rod 1 and a sleeve body 2; one end of the core rod 1 is provided with a head protrusion 11, and the middle part is provided with a broken neck groove 12; A first thread segment 13 is provided from the side facing the head protrusion 11 and toward the head protrusion 11; From one side of the tail of the core rod, a second thread segment 14 is provided in the direction of the tail of the core rod; the sleeve body 2 can be sleeved on the core rod 1, and the sleeve body 2 has a The sleeve body thread segment 21 that the first thread segment 13 is engaged with; when one end of the sleeve body 2 is located on the inner end face 111 of the convex body 11 of the head of the core rod 1, the first thread segment 13 is partially or fully engaged with the threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com