Injection molding bolt for automobile spare tire and production process of injection molding bolt

A production process and bolt technology, applied in the direction of bolts, screws, mechanical equipment, etc., can solve the problems of scrapped injection-molded bolts and insufficient torsional strength, and achieve the effect of convenient installation and disassembly, high torsional strength, and increased output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

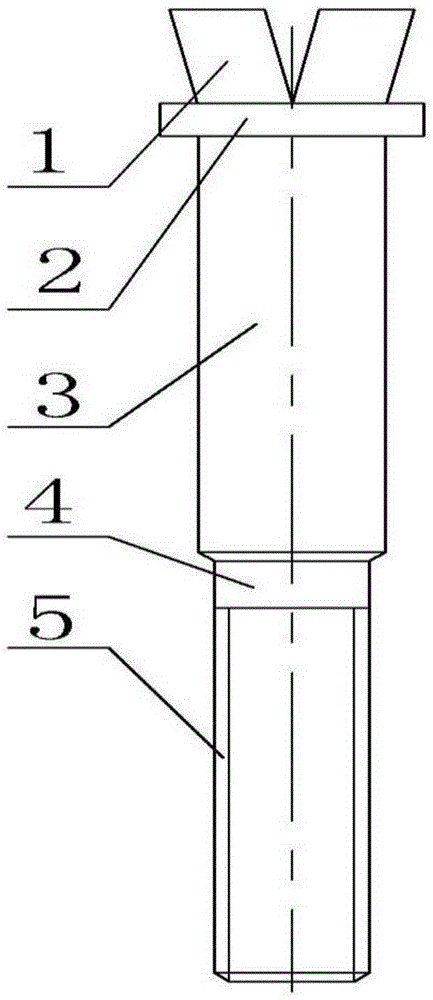

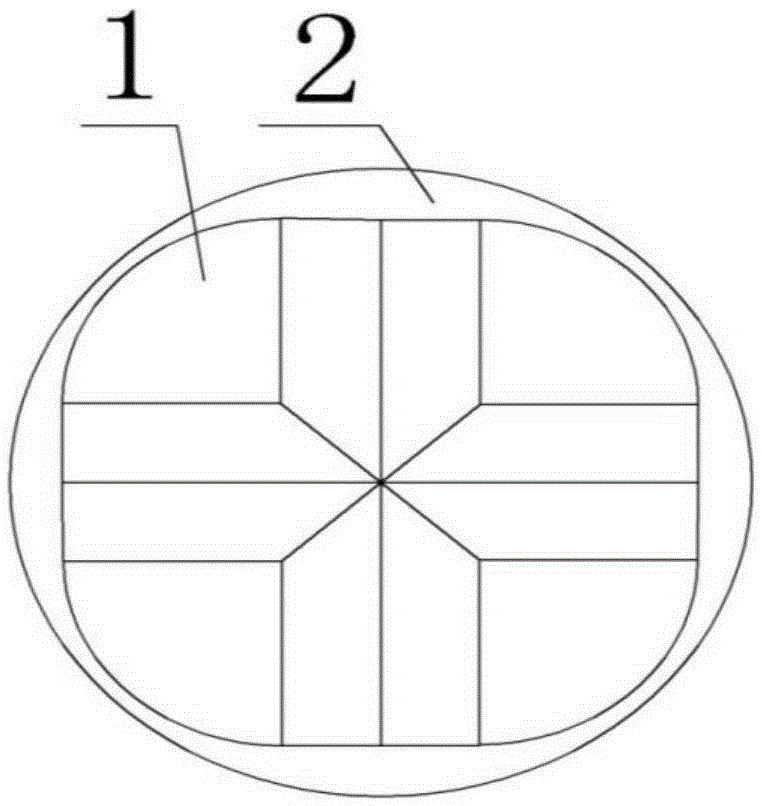

[0022] like figure 1 and figure 2 Shown, a kind of injection molding bolt of automobile spare tire comprises bolt body 3, and bolt body 3 bottom is provided with bolt tail 4, and bolt tail 4 is provided with thread 5, and bolt body 3 top is provided with bolt head 2, and bolt head 2 top Processed with a "ten"-shaped head 1; the length of the thread 5 on the bolt tail 4 is 32-60 mm; the stamping depth of the "ten"-shaped head 1 is 4-10 mm; the outermost side of the bolt head 2 is connected to the bolt body The distance of 3 is 2-5 millimeters.

[0023] When working, the bolt and the injection molded part are injection molded together, and the bolt and the device are fixed together through the thread 5, and the staff can tighten the injection bolt knob by hand. When excessive external force acts, the bolt will not rotate with the head of the injection molded part, which is safe and reliable, and the fixation between the injection molded bolt and the device is completed.

[0...

Embodiment 2

[0034] A kind of production technology step of automobile spare tire injection molding bolt is as follows:

[0035] (1) material selection and initial processing: select a bar stock with a diameter of 23 mm, and initially process the bar stock into a bar stock with a diameter of 20 mm and a length of 1250 mm on a lathe;

[0036] (2) Stamping forming: Put the pre-processed bar into the stamping die, stamp the head of the bar, and process a "ten"-shaped head;

[0037] (3) Finishing and machining threads: the bar is carried out to finish machining to obtain the final size, and the tail of the bar is extruded with an extruder to process the thread, and the length of the thread is 46 millimeters to obtain the preliminary product of the automobile spare tire injection bolt;

[0038] (4) Heat treatment: Firstly quench the finished product of the injection molded bolt for the spare tire of the automobile, then put it into the tempering furnace for tempering, take out the finished prod...

Embodiment 3

[0043] A kind of production technology step of automobile spare tire injection molding bolt is as follows:

[0044] (1) Material selection and initial processing: select a bar with a diameter of 30 mm, and process the bar on a lathe into a bar with a diameter of 28 mm and a length of 1400 mm. If the length of the bar exceeds 1400 mm, the material will be damaged. waste;

[0045] (2) Stamping forming: Put the pre-processed bar into the stamping die, stamp the head of the bar, and process a "ten"-shaped head;

[0046] (3) Finishing and machining thread: the bar is carried out to finish machining to obtain the final size, and the tail of the bar is extruded with an extruder to process the thread. The length of the thread is 60 millimeters to obtain the preliminary product of the automobile spare tire injection bolt;

[0047] (4) Heat treatment: Firstly quench the finished product of the injection molded bolt for the spare tire of the automobile, then put it into the tempering fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com