Optimizing and designing system for dynamic property of fluidic-resistance suspension of automobile powertrain

A technology of automotive powertrain and hydraulic mount, which is applied to mechanical equipment, liquid shock absorbers, combustion engines, etc., can solve the problems of lack of theoretical basis for hydraulic mount, shorten the development cycle, reduce adjustments, Reduce the effect of work on structural improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

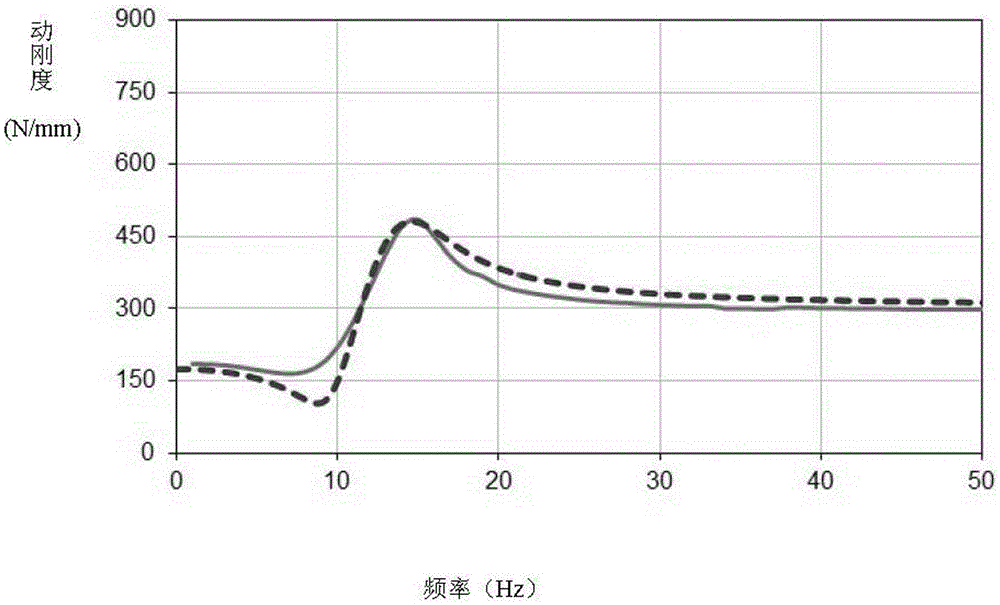

[0021] Depend on Figure 1-4 As shown in Fig. 1, the optimal design of the dynamic characteristics of a horizontal three-point engine side hydraulic mount. Finally, the optimally designed dynamic characteristic curve generated in the optimization design system and the dynamic test of the mount sample optimized by using the optimized design parameters are measured. line contrast.

Embodiment approach

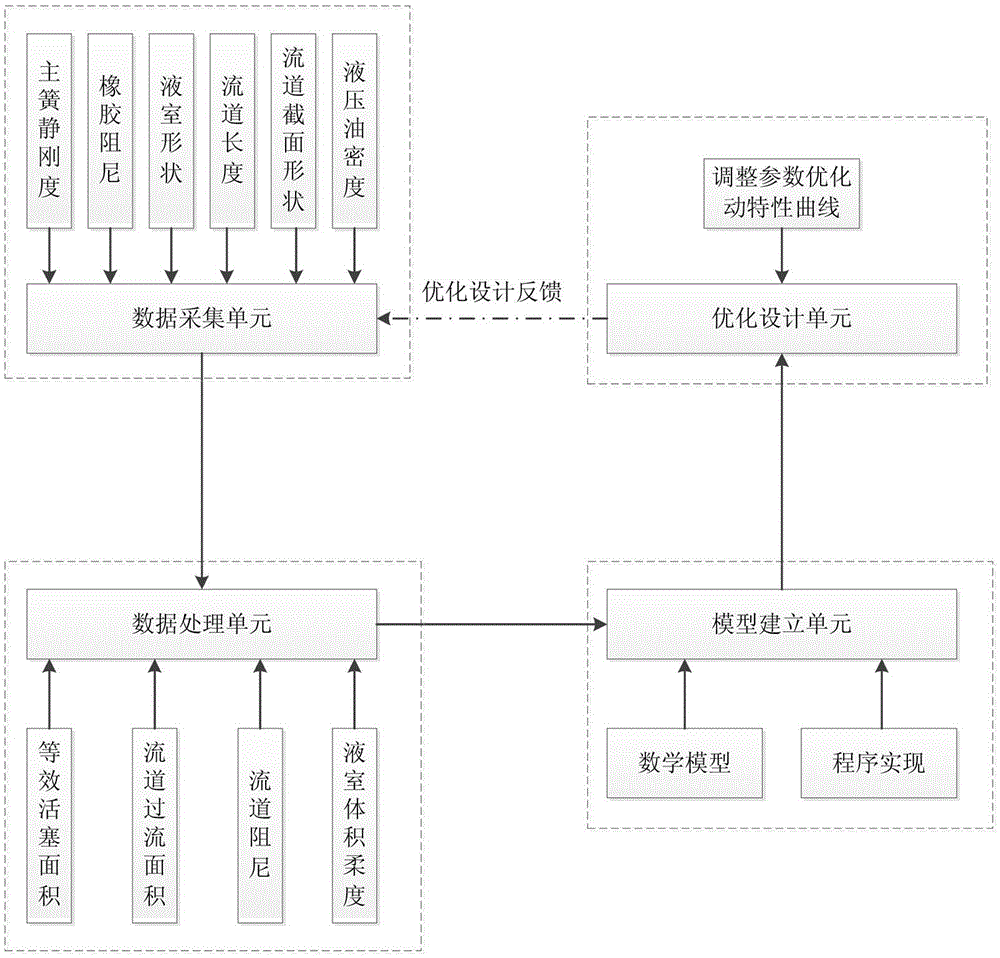

[0022] According to the optimization design system of the suspension dynamic characteristics of the present invention, according to figure 1 The specific implementation method of the system structure schematic diagram in is as follows:

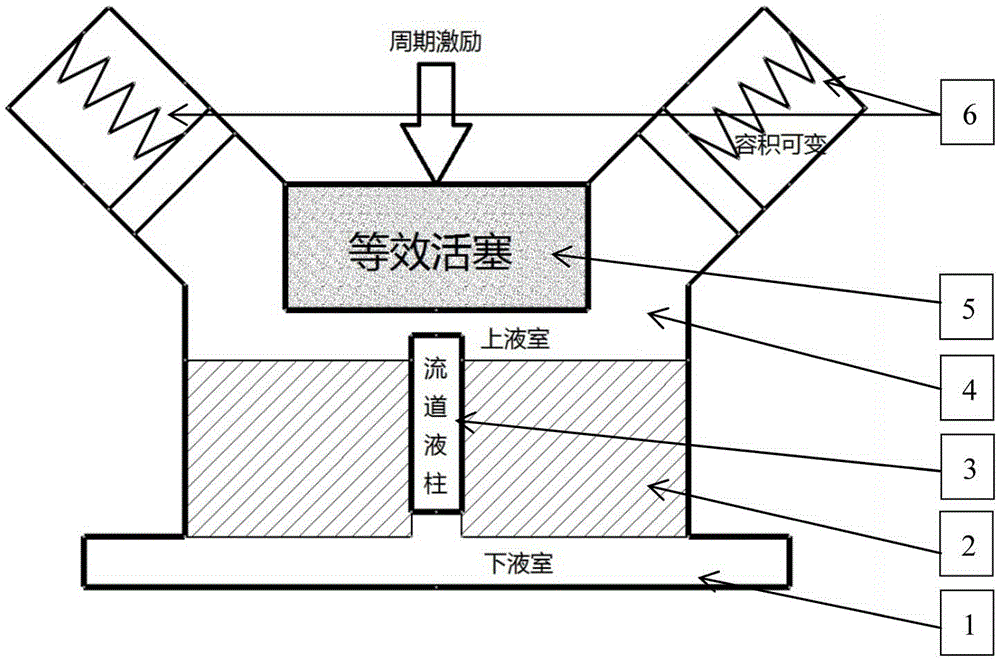

[0023] It includes a data acquisition unit for determining or identifying the relevant parameters of the rubber main spring, the relevant parameters of the liquid chamber, the relevant parameters of the flow channel and the relevant parameters of the hydraulic oil. Connection; the output end of the data processing unit is connected with the input end of the model building unit, and the output end of the model building unit is connected with the input end of the optimization analysis unit;

[0024] The data processing unit refers to performing summary processing according to the collected parameters to obtain the key abstract parameters affecting the dynamic characteristics of the liquid resistance mount required for model building; the model e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com