Microfluidic inspection device and method for operating thereof

An inspection device and microfluidic technology, applied in the direction of measuring devices, fluid controllers, chemical instruments and methods, etc., can solve the problems of low stability wax valve technology difficulty, misjudgment of cardiovascular diseases, etc., to improve stability and seriousness Reality, low price, effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

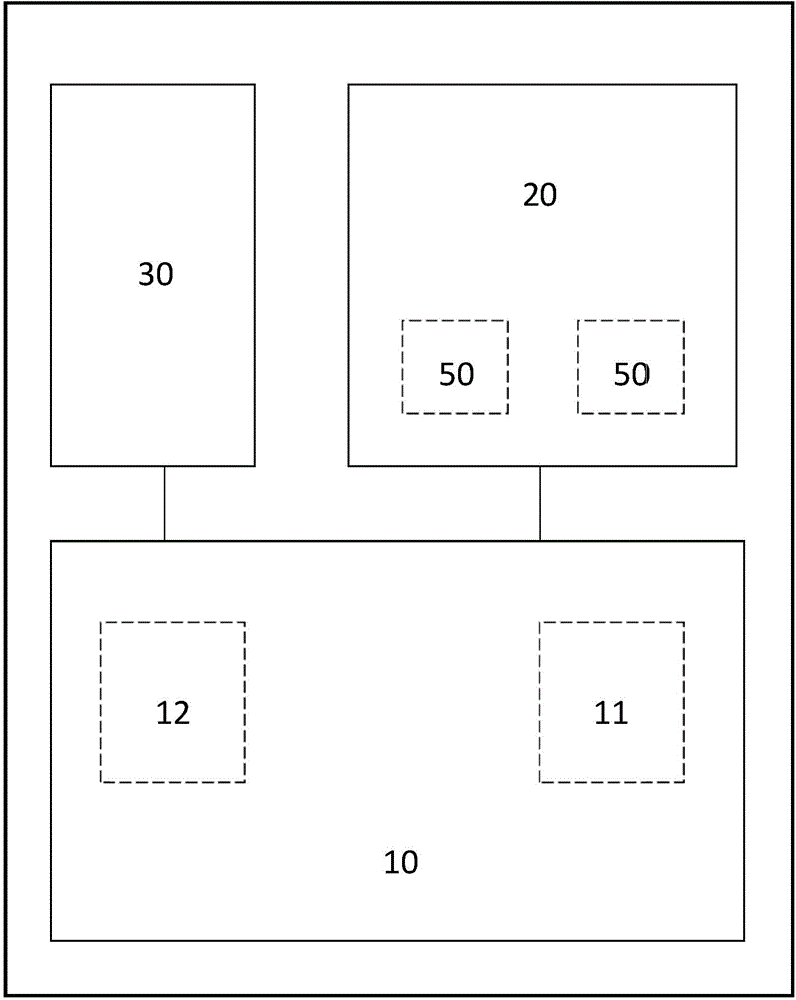

[0030] At least one embodiment of the present invention is a microfluidic testing device, which includes a power module and a microfluidic platform. Wherein, the power module has a rotating unit and an oscillating unit, which are used to drive and control the movement of the microfluidic platform. The microfluidic platform is placed on the power module, has a rotation center and at least one microfluidic structure, and is used for sample pretreatment and sample quantification. Each microfluidic structure further includes a sample injection tank, a certain volume tank and a reaction tank.

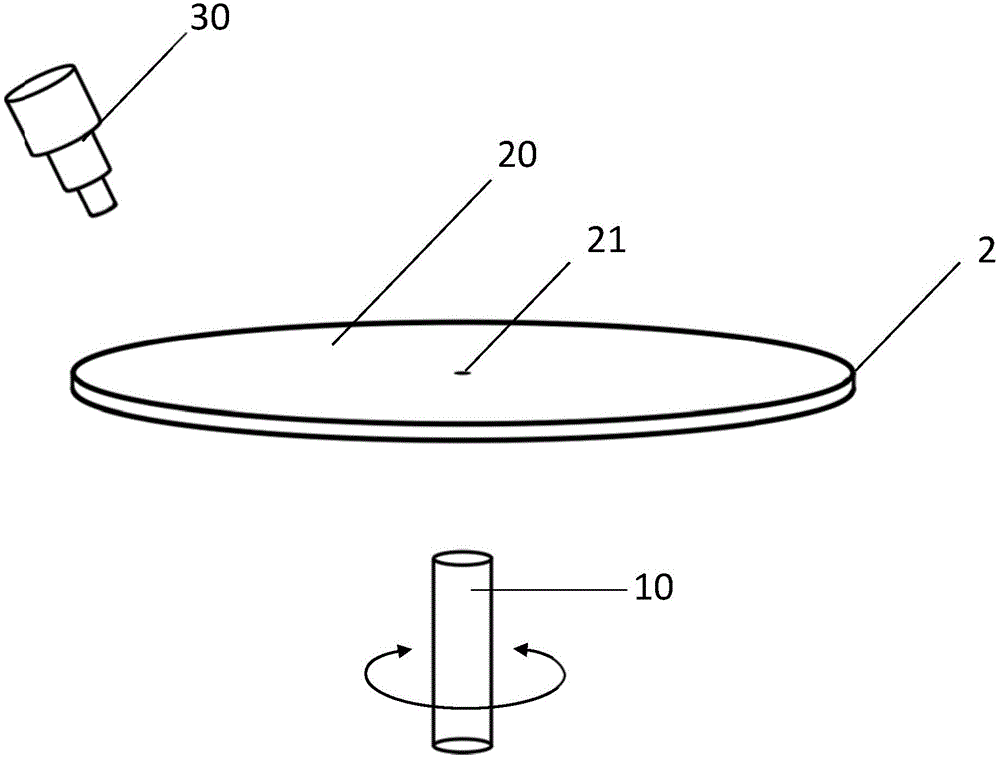

[0031] Figure 1A and Figure 1B It is a schematic diagram of a microfluidic testing device in some embodiments of the present invention. The microfluidic testing device includes a power module 10 and a microfluidic platform 20 . Wherein, the power module 10 has a rotation unit 11 and an oscillation unit 12, which are used to drive and control the movement of the microfluidic platform 20;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com