F35mm mechanical passive-type athermalization lens and assembly method therefor

A passive, lens technology, applied in installation, optics, instruments, etc., can solve the problem of fewer types of lenses, achieve high transmittance, compensate image plane drift, and large relative aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

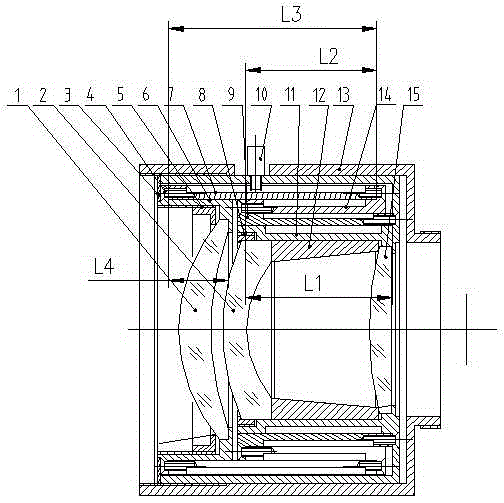

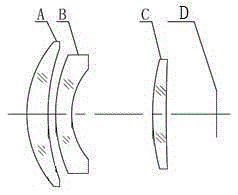

[0026] Such as Figure 1~2 As shown, a f35mm mechanically passive athermalized lens includes an optical system and a mechanical structure. In the optical system of the lens, a positive lens A, a negative lens B, and a positive lens C are sequentially arranged along the light incident direction. The mechanical of the lens The structure includes a front lens barrel 6 and a main lens barrel 11 arranged in sequence along the light incident direction, the front lens barrel 6 is fixedly connected to the main lens barrel 11, a positive lens A is housed in the front lens barrel 6, and the main lens A negative lens B and a positive lens C are accommodated in the barrel 11 .

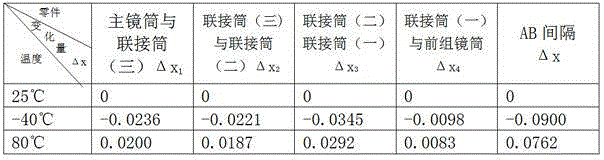

[0027] In this embodiment, the air gap between the positive lens A and the negative lens B is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com