Rolling time domain tracking control method for batch injection molding process

A tracking control, rolling time domain technology, applied in the field of automation, can solve problems such as difficulty in improving controller performance, reducing economic benefits and interference of predictive control systems, and achieve good control effects, improving tracking performance and anti-interference effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Take the injection speed control in the batch injection molding process as an example:

[0052] The injection speed control in the injection molding process is a typical batch process, and the adjustment method is to control the valve opening of the proportional valve.

[0053] Step 1. Establish a state-space model of injection velocity, the specific method is:

[0054] 1.1 First collect the input and output data of the batch injection molding process, and use the data to establish the model of the batch injection molding process in the form as follows

[0055] A(z -1 )y(z)=B(z -1 )u(z)

[0056] A(z -1 )=1+L 1 z -1 +L 2 z -2 +…+L n z -n

[0057] B(z -1 )=S 1 z -1 +S 2 z -2 +…+S m z -m

[0058] where y(z), u(z) are the output and input z transformations of the batch process, respectively, and S, L are the polynomials A(z -1 ), B(z -1 ), m and n are the corresponding coefficients in A(z -1 ), B(z -1 ) of the largest order.

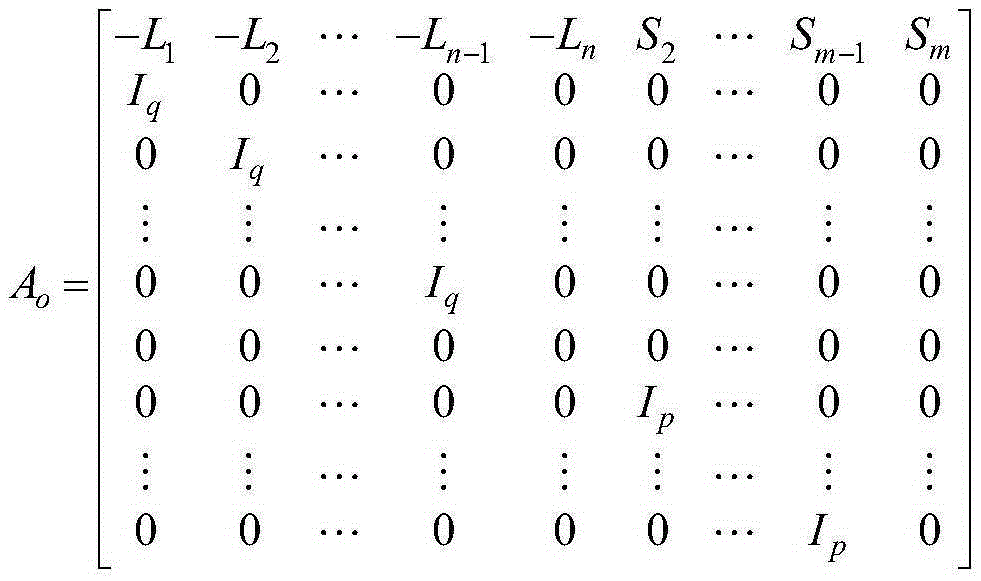

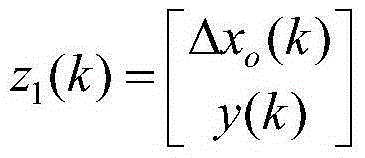

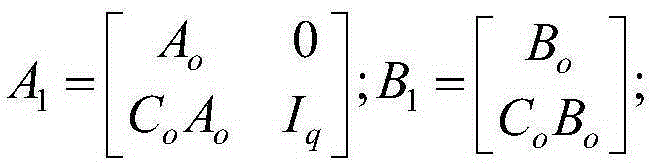

[0059] 1.2 Further proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com