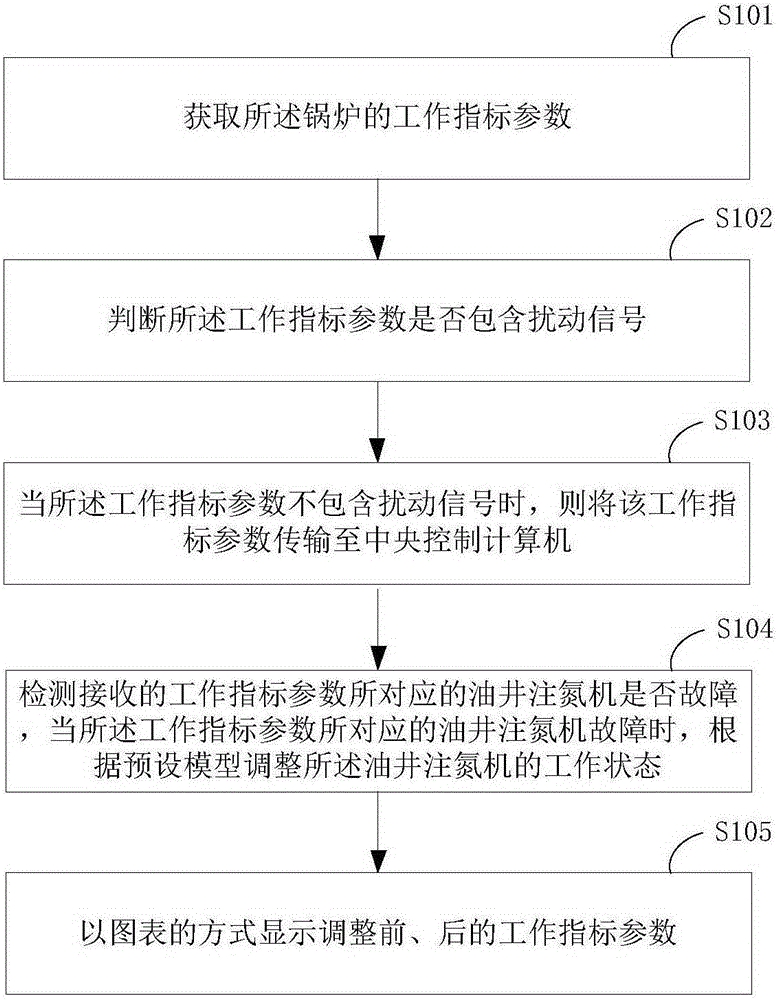

Boiler monitoring method based on Internet of things

An Internet of Things, boiler technology, applied in electrical testing/monitoring, testing/monitoring control systems, program control, etc., can solve problems such as easy accidents, low boiler life, and inability to monitor the working status of boilers in real time, so as to improve accuracy. , to avoid the effect of false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

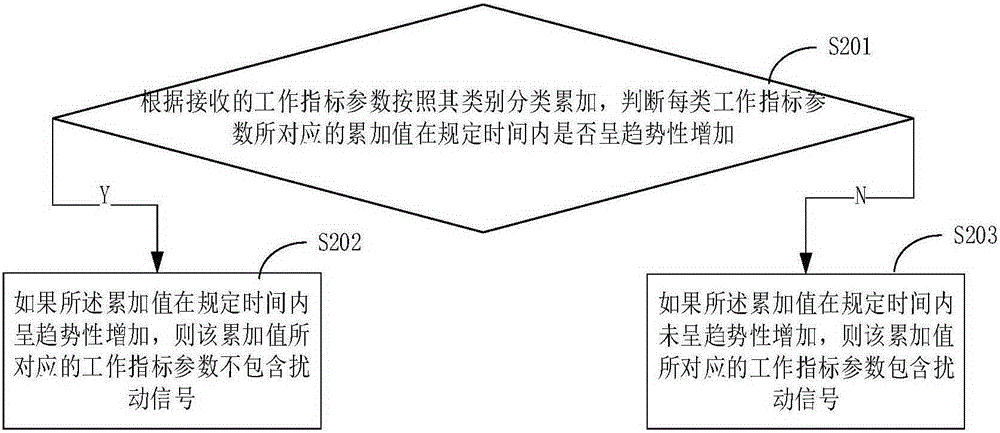

[0045] Such as figure 2 As shown, it is a first implementation of the step S102 of the boiler monitoring method based on the Internet of Things in the embodiment of the present invention; the details are as follows:

[0046] Step S201, according to the classification and accumulation of the received work index parameters according to their categories, it is judged whether the cumulative value corresponding to each type of work index parameter shows a trend increase within a specified time;

[0047] Step S202, if the accumulated value shows a trend increase within the specified time, then the working index parameter corresponding to the accumulated value does not contain a disturbance signal;

[0048]Step S203, if the accumulated value does not show a trend increase within the specified time, then the working index parameter corresponding to the accumulated value contains a disturbance signal;

Embodiment 2

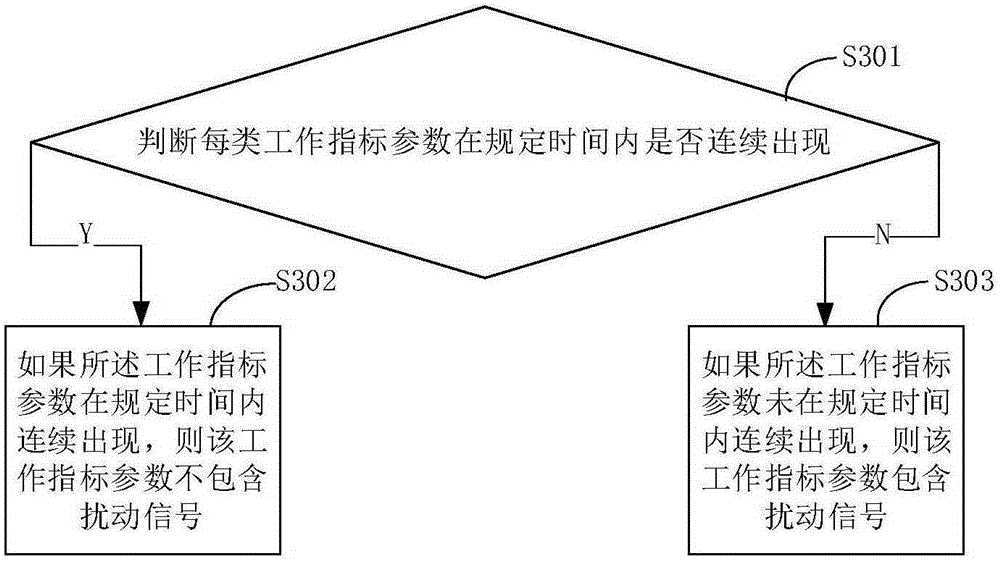

[0050] Such as image 3 As shown, it is a second implementation of the step S102 of the boiler monitoring method based on the Internet of Things in the embodiment of the present invention; the details are as follows:

[0051] Step S301, judging whether each type of work index parameter appears continuously within the specified time;

[0052] Step S302, if the work index parameter appears continuously within the specified time, the work index parameter does not contain a disturbance signal;

[0053] Step S303, if the work index parameter appears continuously within a specified time, the work index parameter contains a disturbance signal.

[0054] In this embodiment, the working index parameters collected by each sensor in the sensor are transmitted to the controller, after A / D conversion, the controller performs analysis and judgment, and the judgment item is whether it is a disturbance signal. Current monitoring products use pulse-triggered alarms for information collection,...

Embodiment 3

[0057] It also includes a mobile terminal, which sends a corresponding query command to the central control system through the mobile terminal, and calls the mobile terminal corresponding to the working state of the boiler according to the received query command, wherein the mobile terminal is a mobile phone, a tablet computer, a palmtop computer, Any one or more of MP4 and MP5. In this embodiment, the corresponding APP program is logged in through the mobile terminal, and the display results of the central control computer are queried or monitored on the mobile terminal.

[0058] When users need to know the working status of boilers across the country, arrange and adjust the operation of oil fields, they only need to sit in the monitoring room and use the central control computer to query the corresponding charts of each boiler based on their working index parameters, or rely on mobile The APP program of the terminal is interconnected with the central control computer to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com