device for reducing the displacement of an elevator car caused by load changes

An elevator car and load change technology, applied in the field of displacement devices, can solve the problems of starting the motor multiple times, uneconomical energy efficiency, falling, etc., and achieve the effects of achieving economies of scale, optimizing energy consumption, and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

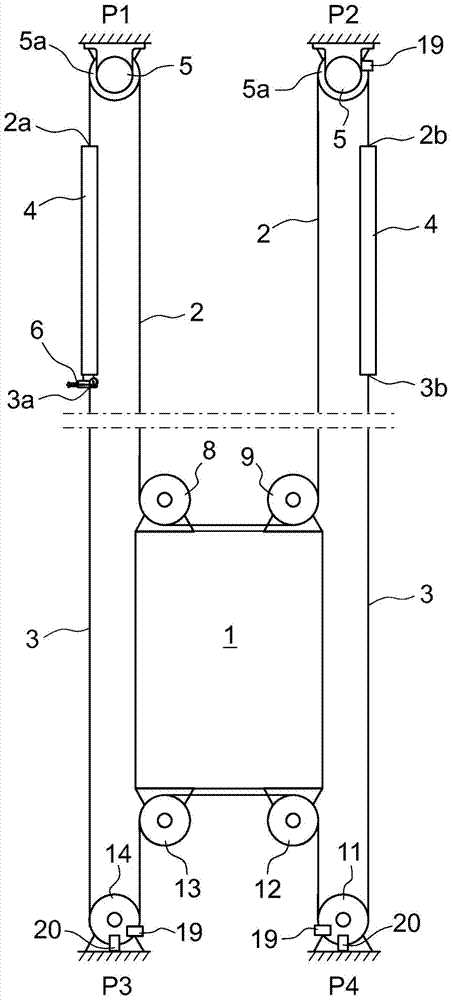

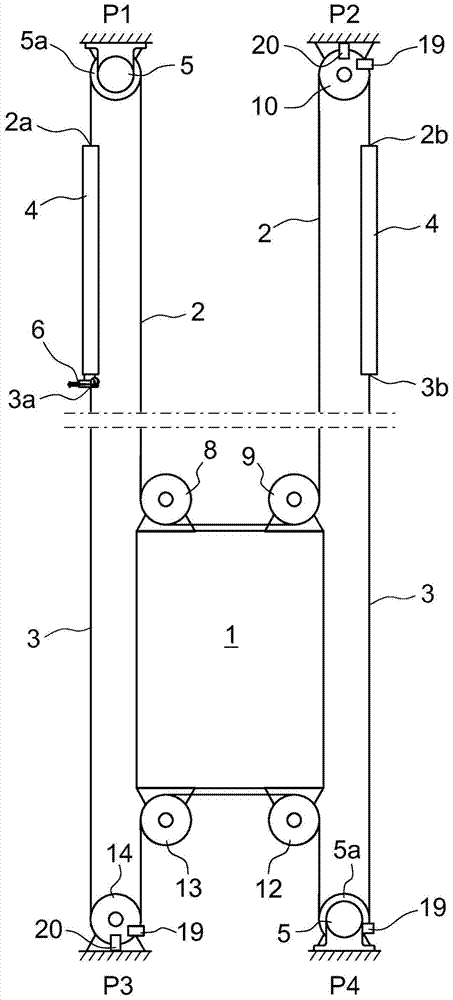

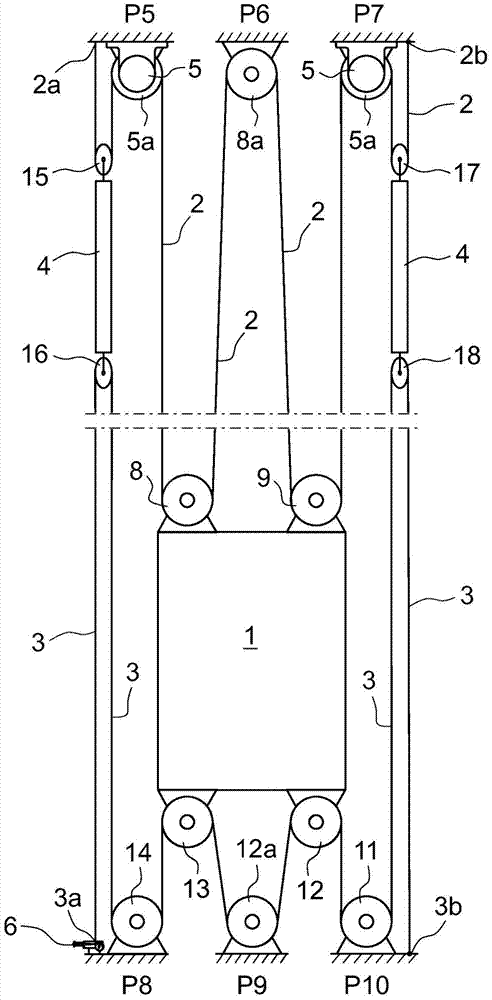

[0020] The displacement of the elevator car and the elongation of the elevator ropes supporting the elevator car caused by load changes, i.e., more precisely, by load changes of the elevator car, can be substantially achieved by using one or more (for example two ) counterweights and are substantially reduced by connecting the counterweights to each other at their bottom ends by means of rope elements or by means of corresponding flexible elements serving in part to support the load. Suspensions of this type, referring to closed systems, are stiffer than conventional suspensions, and expressly this enables smaller displacements to be induced by loads.

[0021] figure 1 A simplified and schematic side view of an elevator installation according to the invention is shown with a 1:1 suspension in which there are two traction machines 5 of the elevator arranged at or close to the top of the elevator shaft. The elevator car 1 and the two counterweights 4 used as compensating weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com