Method of removing a contaminant from a contaminant-containing biological composition useful as a biofuel feedstock

A technology of pollutants and compositions, which is applied in the direction of fat production, fat oil/fat refining, etc., and can solve the problem of unobtainable downstream refining processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The following examples and data are provided to illustrate the invention without intending to limit its scope.

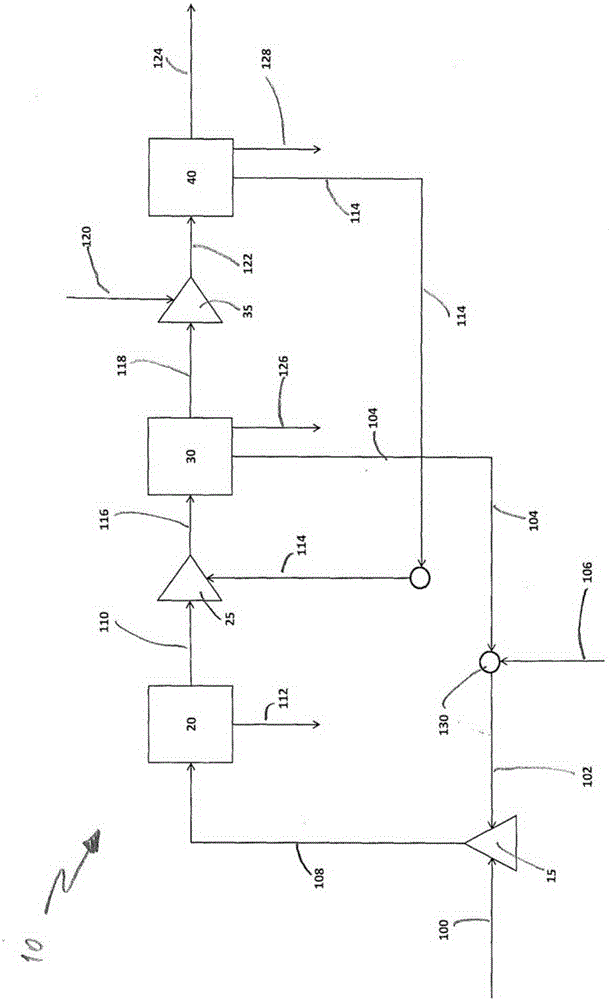

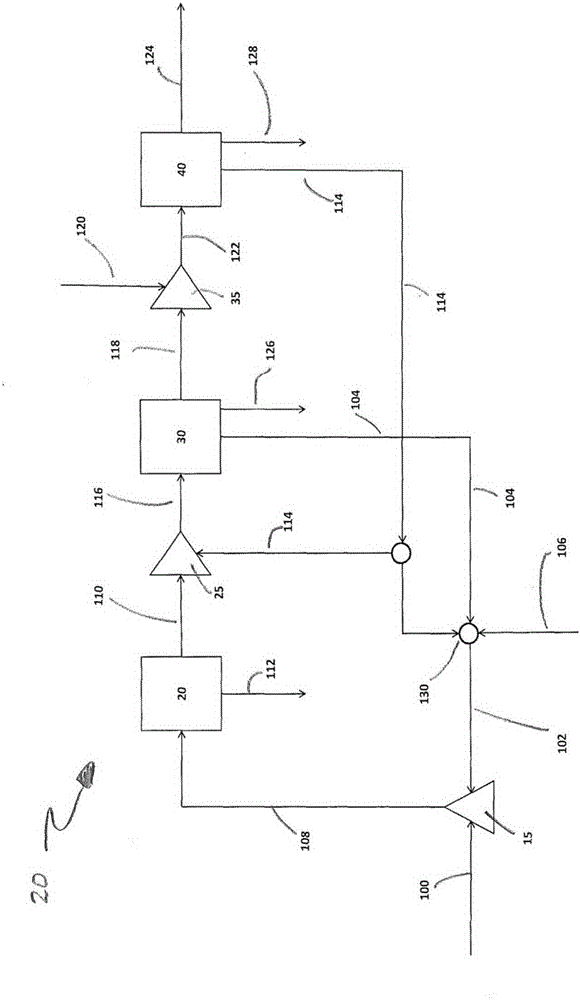

[0041] A pilot scale process was prepared for the tests disclosed below. The process used is as figure 1 with 2 shown, unless otherwise noted.

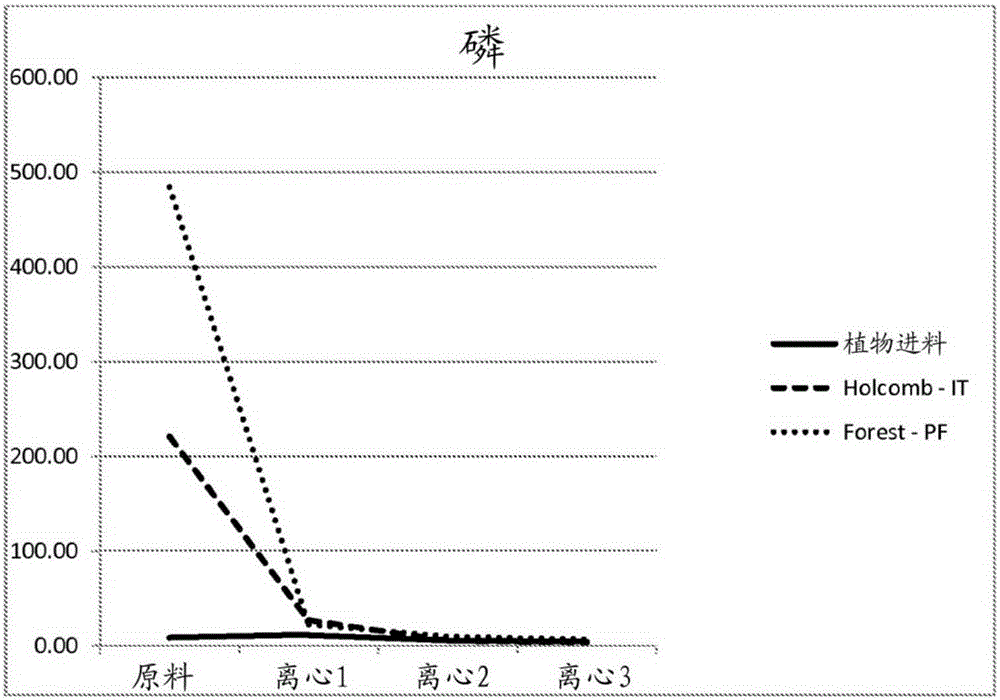

[0042] Water Preparation: This involves mixing the current factory HDO charge pump material with clean deionized water to make the initial water recovered from the third centrifuge. This water is used as the first round of all feed water for the first centrifuge 20 and the second centrifuge 30 respectively. After the first sample of contaminant-containing biological composition (referred to herein as "FOG") has passed through all three centrifugation cycles, the water recovered from the second centrifuge 30 (stream 104) is mixed with the water from the third centrifuge 40. Water (stream 114 ) is used 50 / 50 in the first centrifuge 20 .

[0043] Raw FOG was not filtered. All mixing was simulated by using the blen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com