Backflow anti-blocking drip irrigation system and anti-blocking drip irrigation capillary

A technology of anti-clogging and return pipes, which is applied in the direction of climate change adaptation, horticulture, botany equipment and methods, etc., can solve the problems of high water quality requirements for drip irrigation water sources, and the inability to realize sand and sand discharge, so as to improve the potential of sand and sand discharge , Improve anti-clogging performance, reduce the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

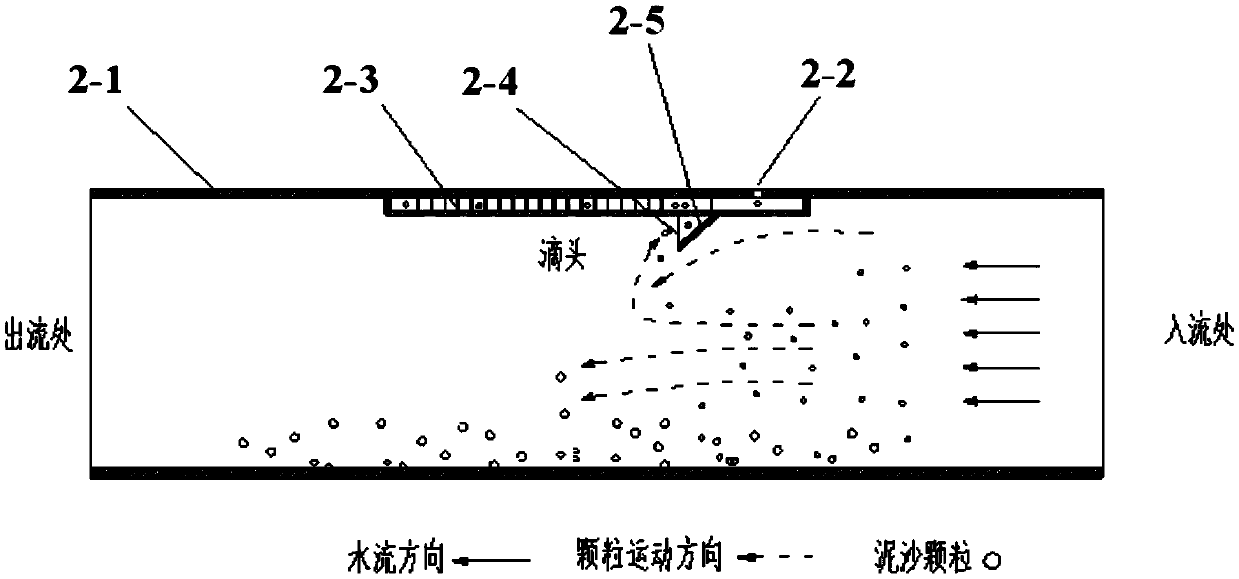

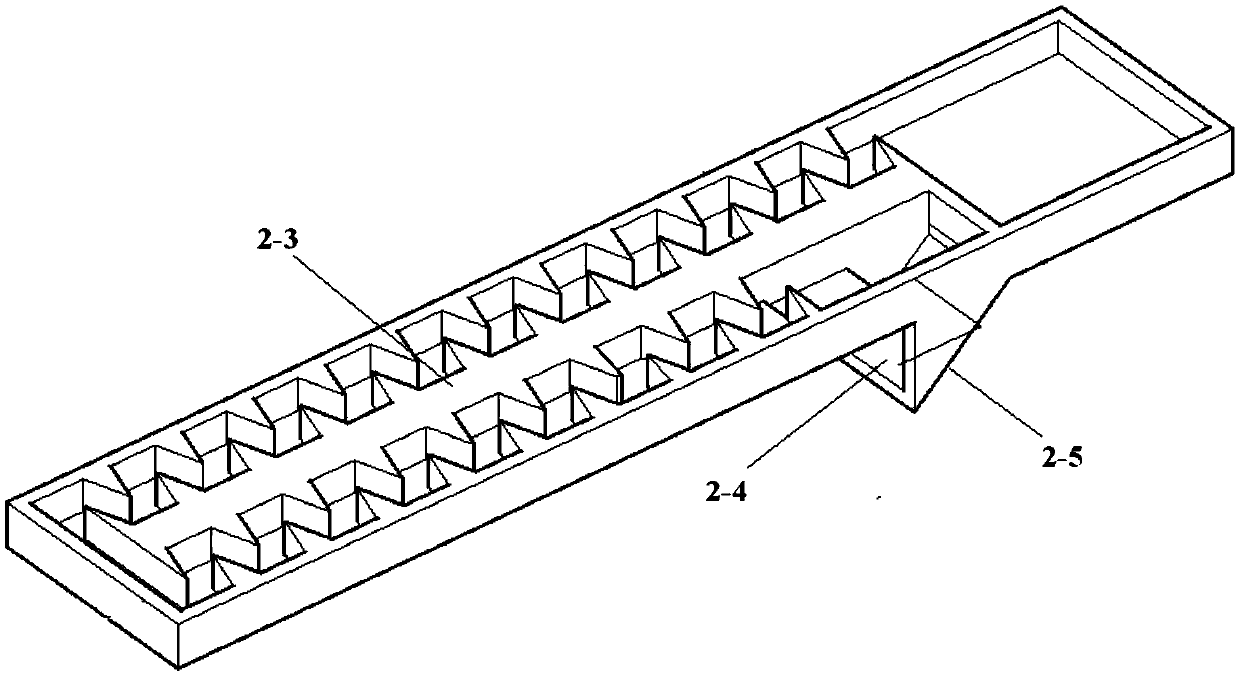

[0031] This embodiment provides a kind of anti-clogging drip irrigation capillary, such as Figure 2 to Figure 4 As shown, the capillary main body 2-1 is included, the capillary main body 2-1 is provided with a water outlet hole 2-2, and the position where the water outlet hole 2-2 is located on the inner wall of the capillary main body 2-1 is installed with an energy dissipation baffle 2-3, the energy dissipation baffle 2-3 is provided with a water inlet 2-4, and the water inlet 2-4 is provided with a semi-closed inclined baffle 2-5, and the opening of the water inlet 2-4 is in the same direction as The mainstream direction of the capillary main body 2-1 is the same, and the water in the capillary main body 2-1 enters the energy dissipation baffle 2-3 from the water inlet 2-4 countercurrently, and then is discharged from the water outlet hole 2-2.

[0032] The included angle between the semi-enclosed inclined baffle 2-5 and the energy dissipation baffle 2-3 is 30°-65°.

[00...

Embodiment 2

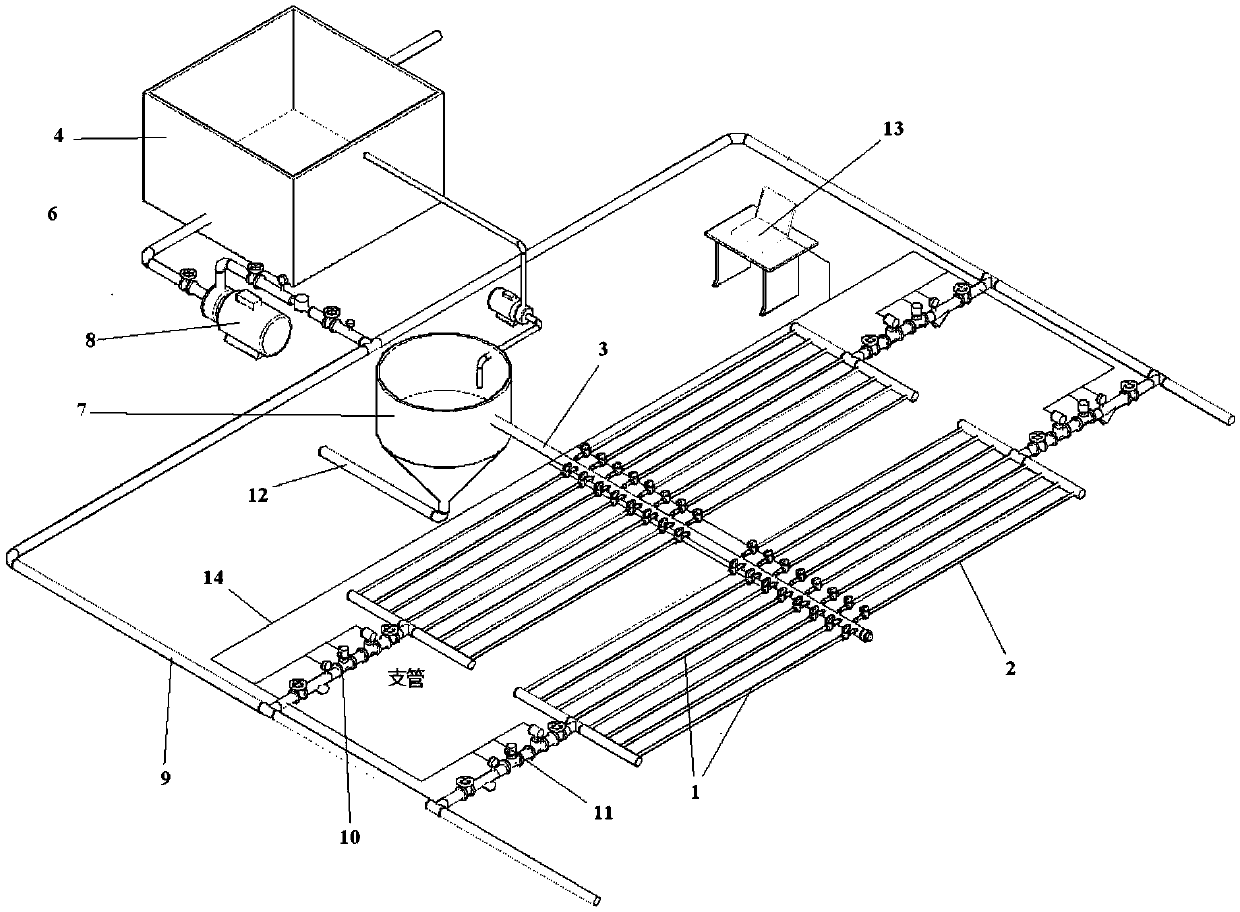

[0037] This embodiment provides a kind of backflow anti-clogging drip irrigation system, such as Figure 1 to Figure 6 As shown, the drip irrigation belt 1 is included, and the drip irrigation belt 1 is composed of a plurality of anti-clogging drip irrigation capillaries 2, and the tail ends of the plurality of anti-clogging drip irrigation capillaries 2 are connected with the return pipe 3, and the return pipe 3 is connected with the water storage tank 4 to form Closed loop drip irrigation system;

[0038] The anti-clogging drip irrigation capillary 2 adopts the anti-clogging drip irrigation capillary in Example 1.

[0039]The tail ends of the plurality of anti-clogging drip irrigation capillaries 2 are all communicated with the return pipe 3 through the return speed regulating valve 5 and the connecting elbow 6 .

[0040] A sediment filter 7 is also arranged between the return pipe 3 and the water storage tank 4 .

[0041] The pressurized water pump 8 at the head end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com