Method for synthesizing high acid resistant MOR zeolite molecular sieve membrane from fluorine-containing dilute solution

A zeolite molecular sieve membrane and zeolite molecular sieve technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as not meeting the requirements of industrial applications, achieve reduced usage, broad application prospects, and save energy The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

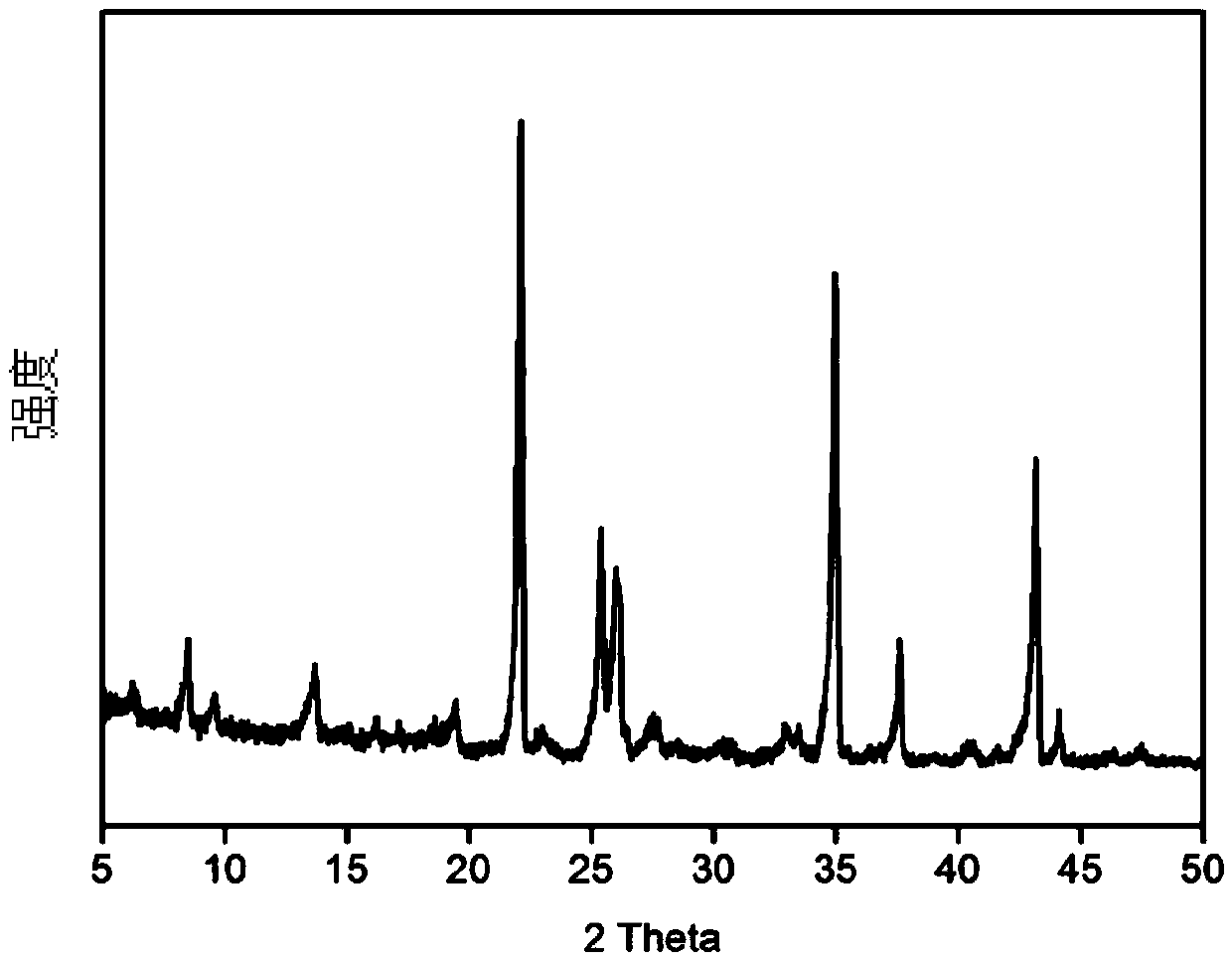

[0030] Prepare the MOR zeolite molecular sieve membrane as follows:

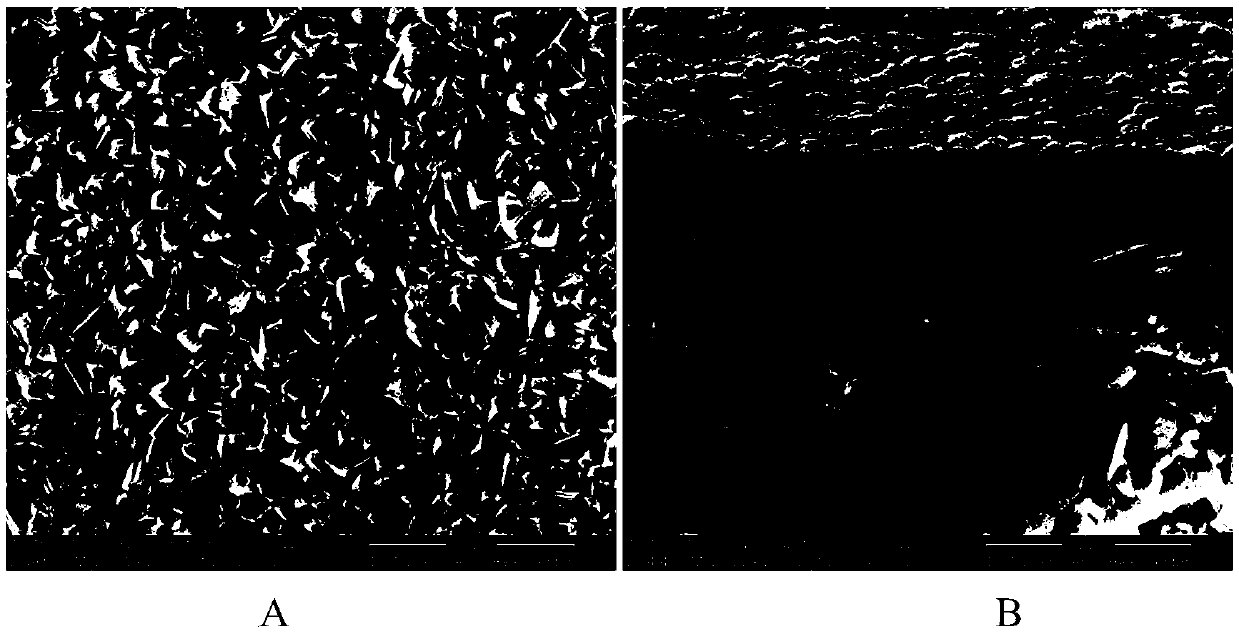

[0031] (1) Treatment of porous carrier tube: the porous carrier used in the synthesis of MOR zeolite molecular sieve membrane is α-Al 2 o 3 The carrier tube has an average pore diameter of 2-3 μm and a porosity of 30%-40%. α-Al 2 o 3 Before the crystal coating, the carrier tube was polished to a smooth surface with sandpaper, then ultrasonically cleaned with deionized water, and finally dried overnight in an oven at 80°C.

[0032] (2) Preparation of MOR zeolite molecular sieve seed liquid: Take 0.5g MOR zeolite molecular sieve (Shanghai Zhuohua) and add 100g deionized water to prepare a mass fraction of 0.5wt% MOR zeolite molecular sieve aqueous solution as the seed liquid, and ultrasonically stir the seed liquid After each 30min, the α-Al 2 o 3 The above-mentioned MOR zeolite molecular sieve was introduced into the carrier tube, dried at 80° C. for 8 hours, and then used as a seed tube for future use....

Embodiment 2

[0041] The same operation as in Example 1, except that the seed liquid concentration (MOR zeolite molecular sieve aqueous solution) is 0.2wt%, the pervaporation separation performance of the synthesized MOR zeolite molecular sieve membrane is slightly lower than that of Example 1, but the separation factor remains. Up to 10,000 or more. For dehydration of 90wt% acetic acid, at 75°C, the permeate flux is 0.64kg / m 2 h.

Embodiment 3

[0043] The same operation as in Example 1, except for α-Al 2 o 3 The pore diameter of the carrier tube is about 100 nm, and the pervaporation separation performance of the synthesized MOR zeolite molecular sieve membrane is better than that of Example 1. For dehydration of 90wt% acetic acid, at 75°C, the permeate flux is 0.92kg / m 2 h, the separation factor is as high as 10,000 or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com