Transmission chain type feeding positioning mechanism

A positioning mechanism and transmission chain technology, applied in metal processing and other directions, can solve the problems of high labor intensity, low precision, low work efficiency, etc., and achieve the effects of good versatility, high positioning accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

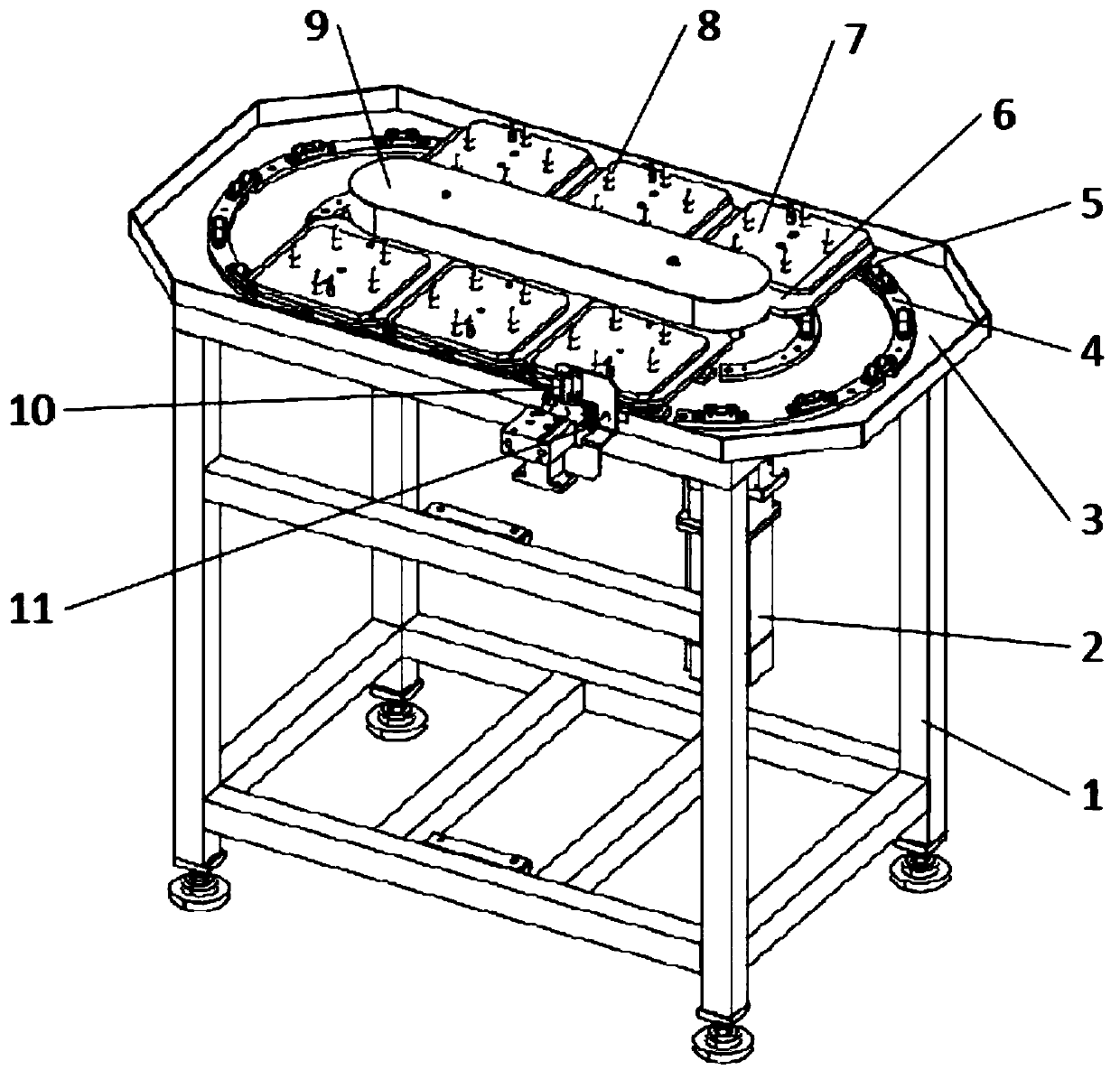

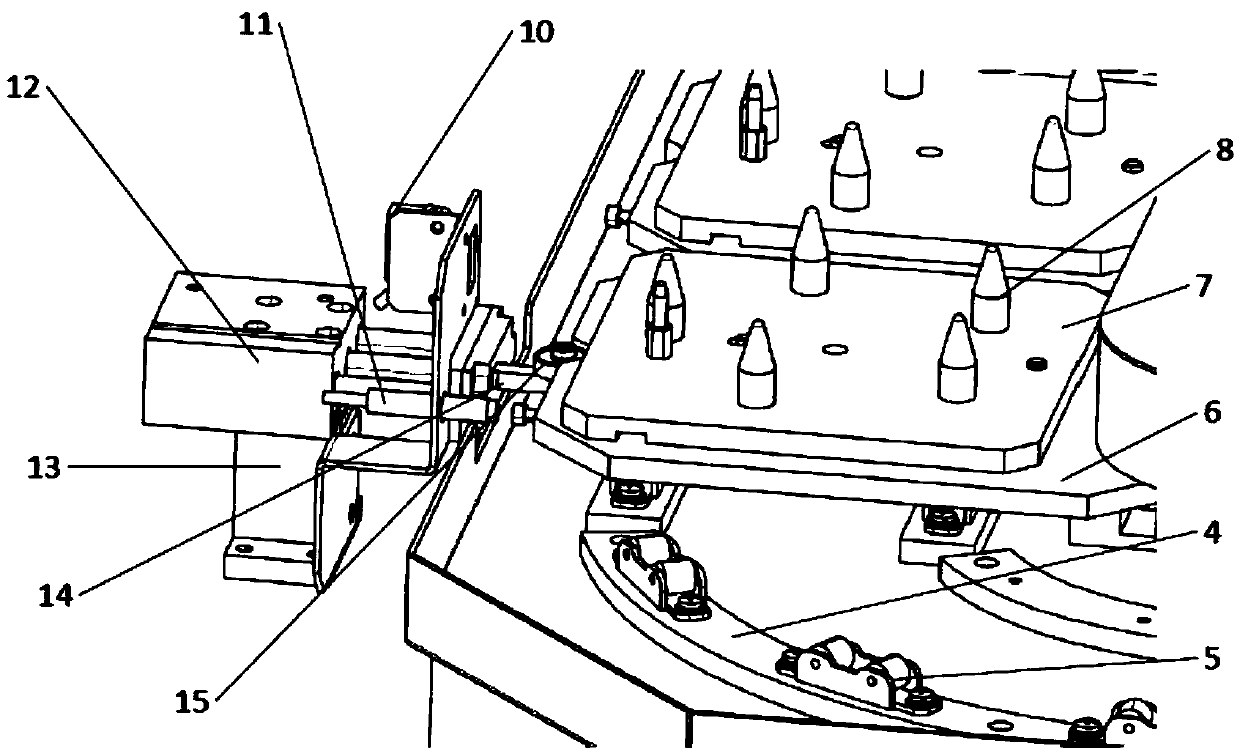

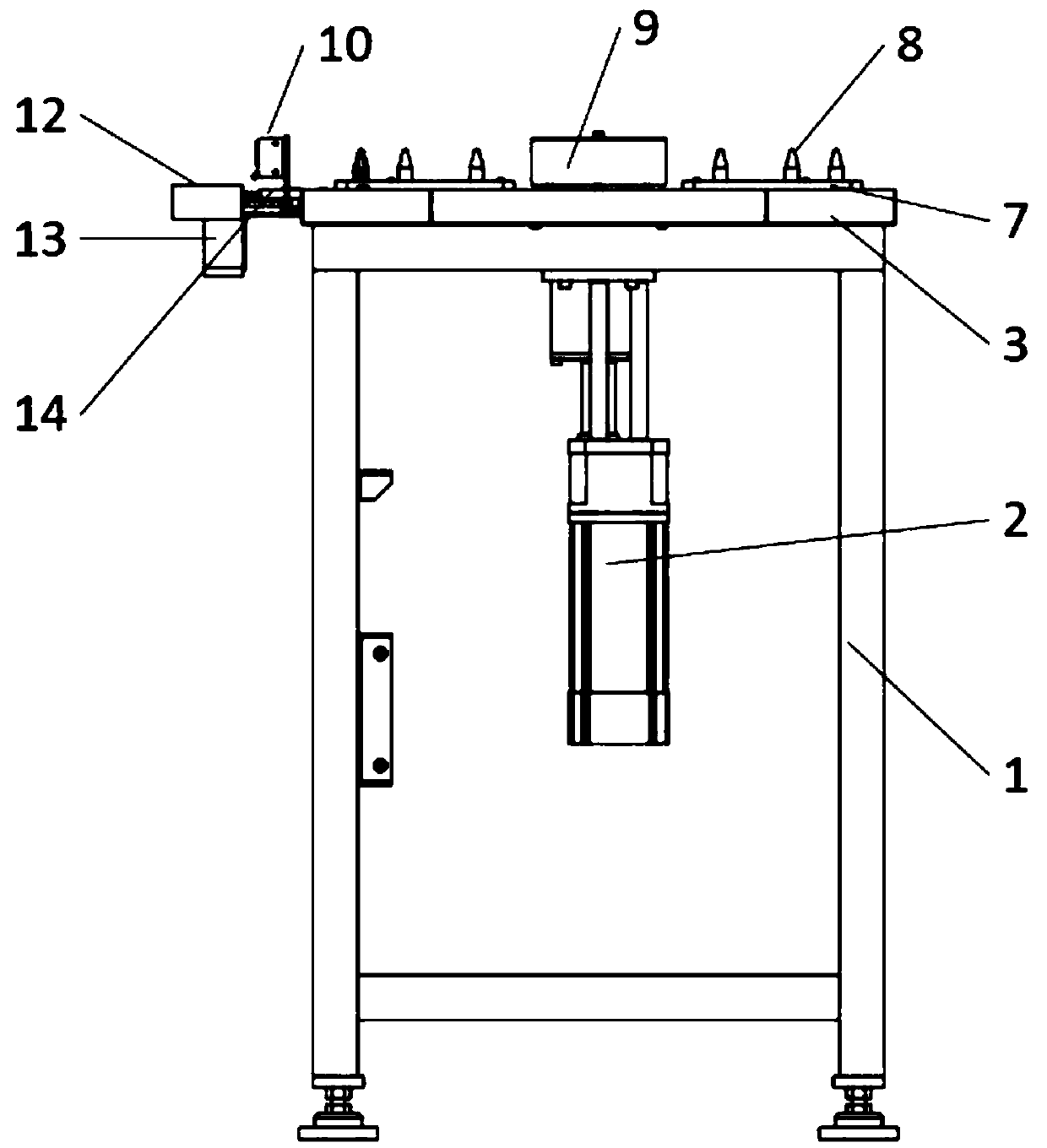

[0014] refer to Figure 1 ~ Figure 3 , a transmission chain type feeding positioning mechanism, comprising a chassis 1, a feeding table 3 and a transmission chain device 9, the upper end surface of the feeding table 3 is provided with a ring guide rail 4, and the ring guide rail 4 is provided with a pulley 5. The pulley 5 is fixed on the pulley guide rail 4 by screws; the pulley 5 is provided with a base 6, one end of the base 6 is fixed with the transmission chain device 9, the base 6 is provided with a tray 7, and the tray 7 is provided with Locating pin 8, is used for fixing parts to be grasped; The lower end face of described feeding table top 3 is provided with the drive motor 2 that is used to drive transmission chain device 9; One side of described feeding table top 3 is provided with positioning photoelectric sensor 11 and The reflective photoelectric sensor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com