Bleaching treatment process for modified poplar material for furniture manufacturing

A processing technology and modification technology, applied in wood treatment, wood treatment details, wood processing appliances, etc., can solve the problems of late wood color difference of heartwood, uneven color of surface wood, unable to meet the requirements of furniture production, etc., to meet the requirements , good bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

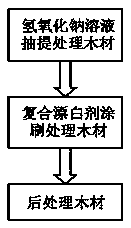

Image

Examples

Embodiment 1

[0019] The specific processing method is as follows:

[0020] a) Sodium hydroxide solution extracts and treats wood. First, a sodium hydroxide solution with a concentration of 0.18% is prepared, and then the surface of the modified poplar board is sanded with a semi-automatic sander and No. 80 sandpaper, and then the surface is sanded with sodium hydroxide The modified poplar wood board was treated by solution extraction for 18h. This extraction treatment can increase the permeability of the bleaching agent during bleaching and the stability of the color of the bleached wood.

[0021] b) Compound bleaching agent brushing treatment of wood, the specific treatment process is as follows: first, mix 42% hydrogen peroxide, 8% ammonia water, and 50% water evenly according to the mass percentage, and prepare a compound bleaching agent, in which the concentration of hydrogen peroxide is 30% , the concentration of ammonia water is 25%; then the modified poplar board treated in step a)...

Embodiment 2

[0024] The specific processing method is as follows:

[0025] a) Sodium hydroxide solution extracts and treats wood. First, a sodium hydroxide solution with a concentration of 0.24% is prepared, and then the surface of the modified poplar board is sanded with a semi-automatic sander and No. 80 sandpaper, and then the surface is sanded with sodium hydroxide The modified poplar board was treated with solution extraction for 15 hours. This extraction treatment can increase the permeability of the bleaching agent during bleaching and the stability of the color of the bleached wood.

[0026] b) Treat wood with compound bleaching agent by brushing. The specific treatment process is: first, mix 44% hydrogen peroxide, 9% ammonia water, and 47% water according to the mass percentage to prepare a compound bleaching agent. The concentration of hydrogen peroxide is 30%. , the concentration of ammonia water is 25%; then the modified poplar board treated in step a) is bleached for the firs...

Embodiment 3

[0029] The specific processing method is as follows:

[0030] a) Sodium hydroxide solution extracts and treats wood. First, a sodium hydroxide solution with a concentration of 0.3% is prepared, and then the surface of the modified poplar board is sanded with a semi-automatic sander and No. 80 sandpaper, and then the surface is sanded with sodium hydroxide The modified poplar wood board was treated by solution extraction for 12 hours. This extraction treatment can increase the permeability of the bleaching agent during bleaching and the stability of the color of the bleached wood.

[0031] b) Treat wood with compound bleaching agent by brushing. The specific treatment process is: first, mix 45% hydrogen peroxide, 10% ammonia water, and 45% water according to the mass percentage to prepare a compound bleaching agent. The concentration of hydrogen peroxide is 30%. , the concentration of ammonia water is 25%; then the modified poplar board treated in step a) is bleached for the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com