Gluing device for packing paper

A gluing device and wrapping paper technology, applied in the field of packaging, can solve the problems of affecting processing efficiency, processing quality, increasing labor intensity, poor continuity of processing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

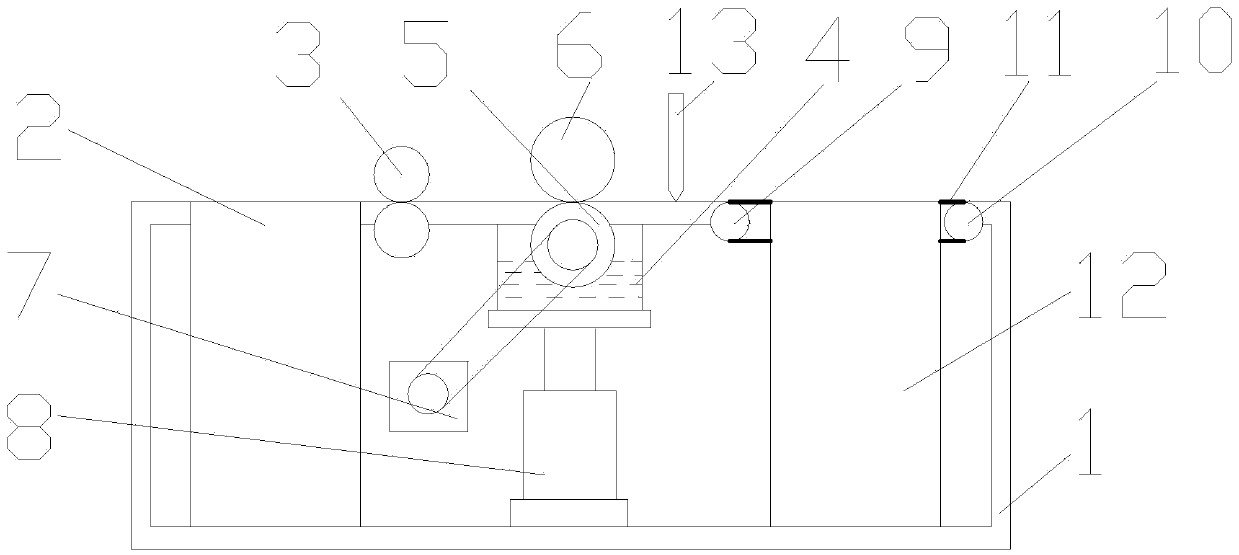

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a wrapping paper gluing device proposed by the present invention.

[0013] refer to figure 1 A wrapping paper gluing device proposed by the present invention includes: a frame 1, a feeding platform 2, a material guiding mechanism, a gluing mechanism, a discharging mechanism and an operating platform; a feeding platform 2, a material guiding mechanism, a gluing mechanism, The discharge mechanism is arranged on the frame 1 in turn, the material guide mechanism includes at least one material guide roller 3; the glue application mechanism includes a glue storage tank 4, a glue roller 5, a pressure roller 6, a first drive device 7, and a second drive device 8 and the liquid level sensor, the glue roller 5 is located above the glue storage tank 4, the glue roller 5 is driven to rotate by the first drive device 7, the pressure roller 6 is located above the glue roller 5, and between the pressure roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com