The working platform of the slag mechanism

A technology of working platform and traveling mechanism, which is applied to conveyors, mechanical conveyors, rotary conveyors, etc., can solve the problems of small working range of slag smashing machine, and achieve the effects of small investment, reduced load and large working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

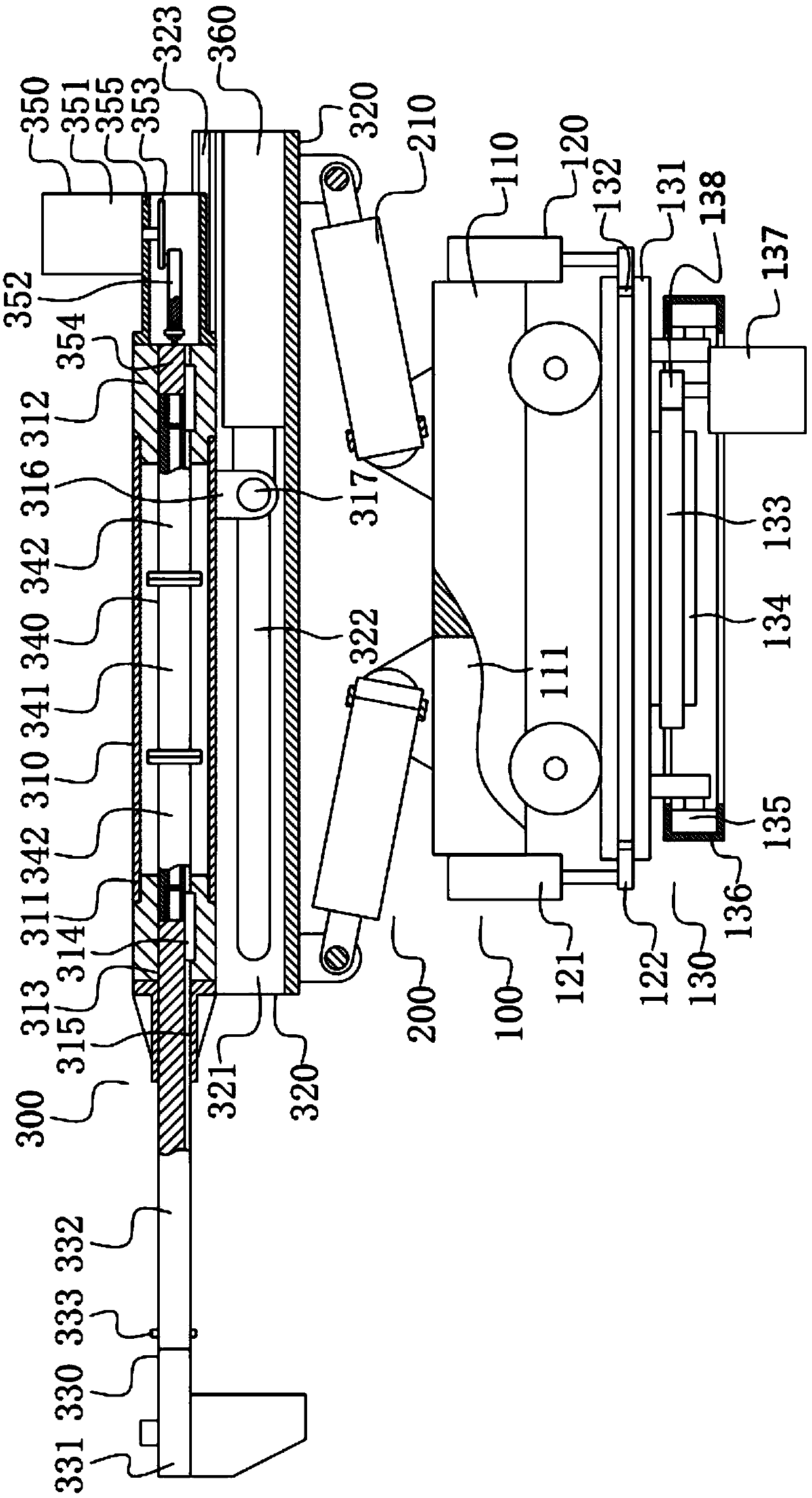

[0014] The working platform of the slag mechanism of the present invention includes a traveling mechanism 100, a turning mechanism 200 and a hydraulic system, and the hydraulic system and the traveling mechanism 100 are split structures; the traveling mechanism 100 includes a trolley 110, a locking mechanism 120 and a rotating mechanism 130; the rotating mechanism 130 includes an annular guide rail 136 and a turntable 131, the turntable 131 is installed on the annular guide rail 136, the trolley 110 is fixed on the turntable 131 through the locking mechanism 120 and rotates around the axis of the turntable 131 with the turntable 131; Turning mechanism 200 comprises a pair of turning oil cylinder 210 and support arm 320, and the cylinder body and piston rod of described turning oil cylinder 210 are respectively hinged with traveling mechanism 100 and supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com