Positioning basketry for glass processing

A glass and basket technology, applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve the problems of increasing production cost, increasing glass breakage, glass breaking, etc., to ensure accuracy, reliability, consistency, and The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

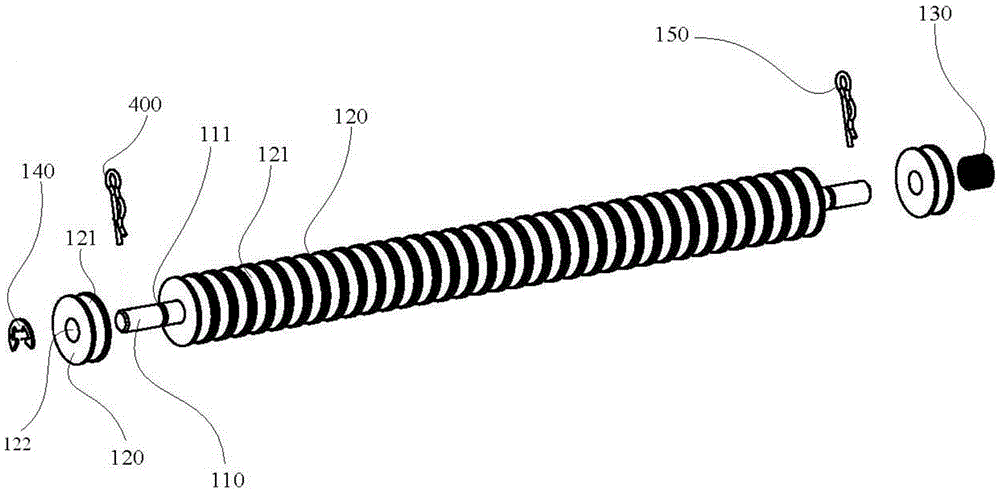

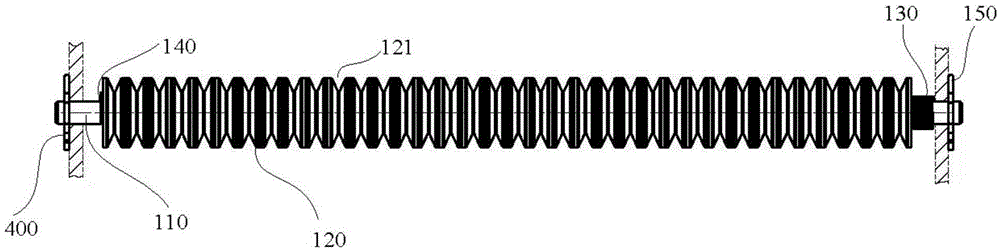

[0034] A positioning rack used in a positioning basket for glass processing, such as figure 1 As shown, it includes: a support rod 110, a toothed bead 120, an elastic member 130, a first fixing member 140 and a second fixing member 150, and the said supporting rod 110 is provided with a toothed bead 120 and an elastic member 130 which are closely installed in sequence, There are several tooth beads 120, all of which are set side by side on the pole 110, and the tooth beads 120 are provided with positioning grooves 121 for placing glass; the first fixing part 140 and the second fixing part 150 are used to place The position of the tooth bead 120 and the elastic member 130 in the axial direction of the strut 110 is fixed, such as figure 2 shown.

[0035] The above positioning rack 100 for glass processing adopts a plurality of tooth beads 120 closely arranged side by side, and each tooth bead 120 is provided with a positioning groove 121 to form a rack-shaped structure for pla...

Embodiment 2

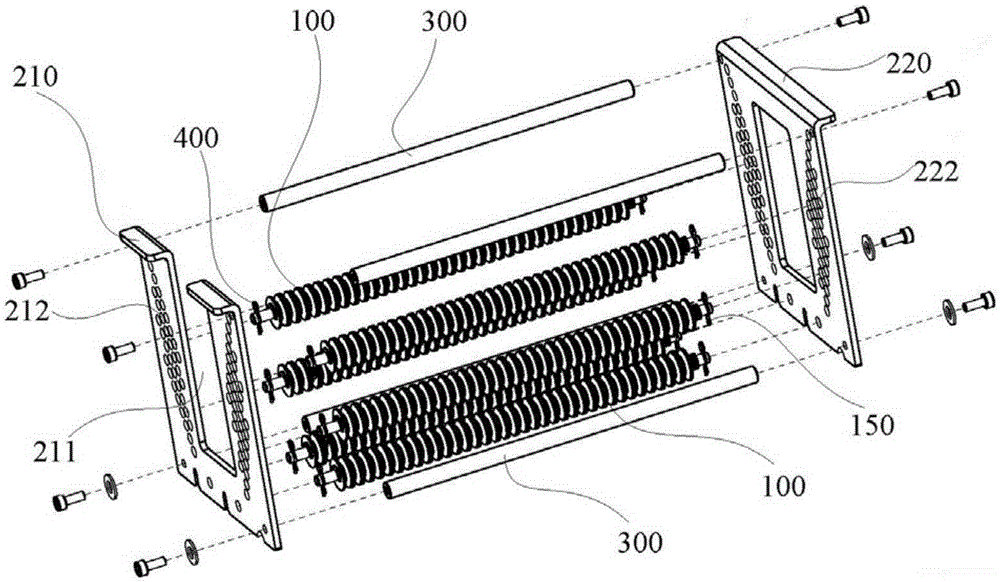

[0044] A positioning basket for glass processing, the positioning basket includes: a positioning rack 100, a side plate, a support rod 300, such as image 3 shown.

[0045] The positioning rack 100 is the positioning rack described in Embodiment 1.

[0046] The side plate includes a first side plate 210 and a second side plate 220, the first side plate 210 is provided with a first rack hole 212, and the second side plate 220 is provided with a second rack hole 222 One end of the pole 110 is fixed on the first side plate 210 through the first rack hole 212 , and the other end is fixed on the second side plate 220 through the second rack hole 222 .

[0047] One end of the support rod 300 is fixed on the first side plate 210 , and the other end is fixed on the second side plate 220 , and the side plate and the support rod form a frame structure.

[0048] In this embodiment, the first side plate 210 is also provided with a U-shaped groove 211, and the U-shaped groove 211 is open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com