A large texturing machine

A texturing machine, a large-scale technology, applied in the direction of textiles and papermaking, etc., can solve the problems affecting the quality of finished yarns, yarns are easy to entangle with each other, and yarn tension is unstable, so as to improve equipment production efficiency and avoid yarn shedding , Guarantee the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

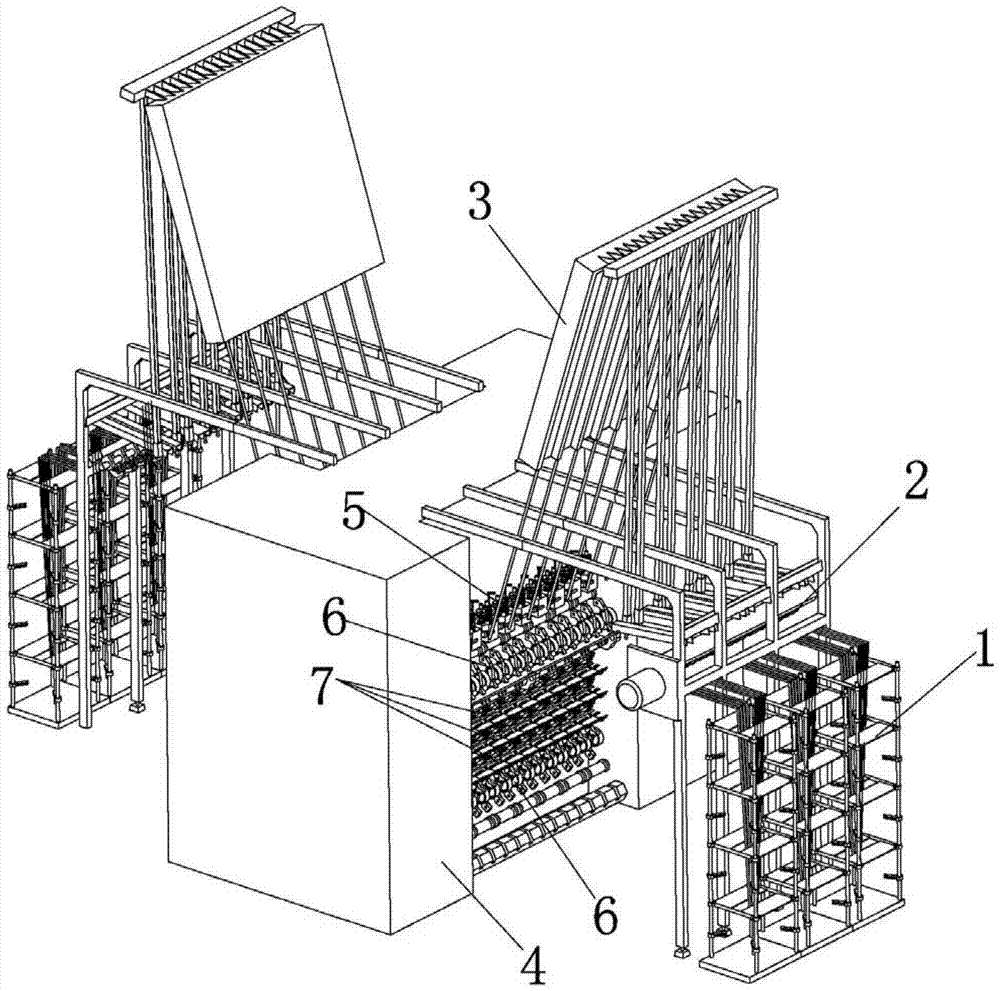

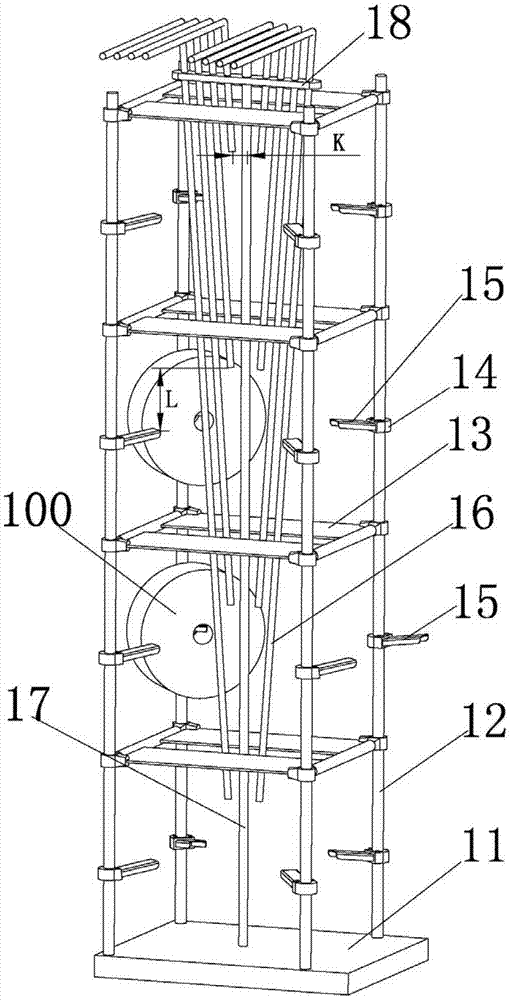

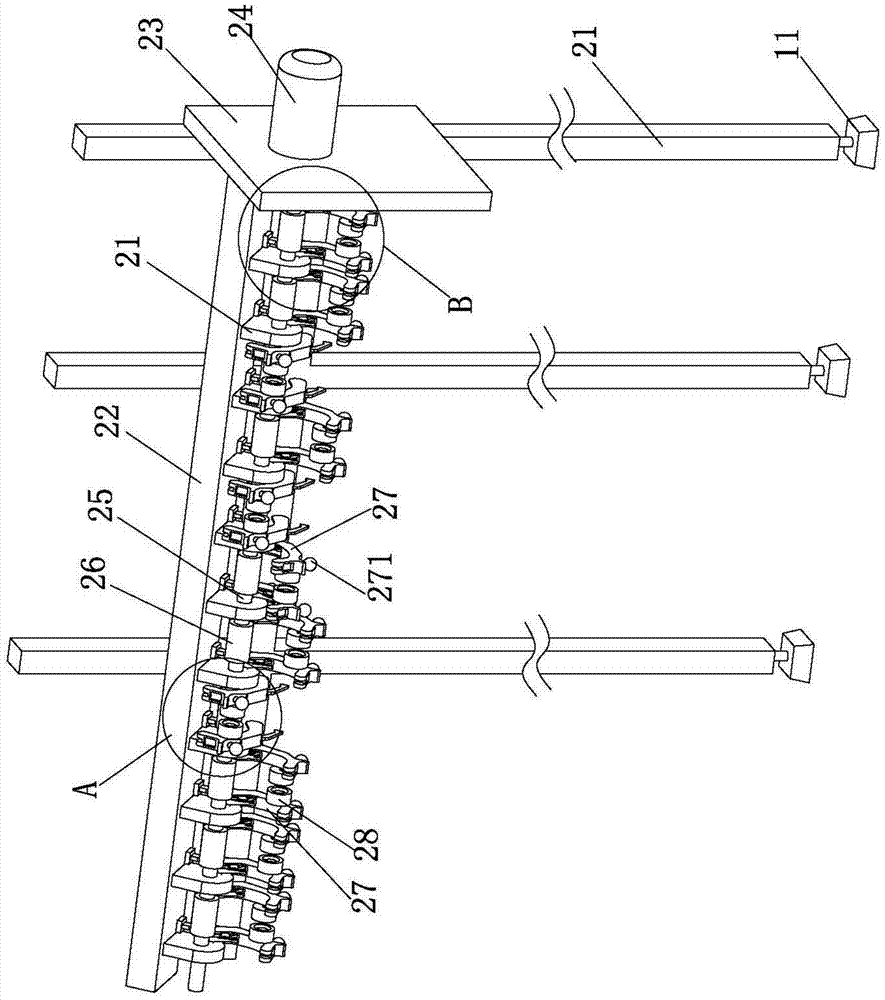

[0041] Please refer to the attached figure 1 To attach Figure 8 Shown, the present invention is a kind of large-scale texturing machine, and it is left-right symmetrical arrangement, by creel device 1, the first yarn feeding roller mechanism 2, deformation heating box 3, main frame 4, false twister 5, the second sending Several parts such as yarn roller mechanism 6 and winding mechanism 7 are formed.

[0042] Wherein, the creel device 1 is arranged outside the main frame 4, on which the raw silk bobbin 100 can be placed. The first yarn feeding roller mechanism 2 is installed on the top side of the creel device 1, and it is used for conveying raw silk. The deformation heating box 3 is arranged above the creel device 1 and the main frame 4, and it is used to heat the raw silk, thereby facilitating the deformation of the raw silk. The false twister 5, the second yarn delivery roller mechanism 6, the three-layer winding mechanism 7 and the second yarn delivery roller mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com