Novel heat accumulating type compressed air energy storage system

A technology of compressed air energy storage and compressed air, applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve the problems of low system operation efficiency, low heat energy utilization rate, unreasonable system flow, etc., and achieve simple and compact structure, High system efficiency and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

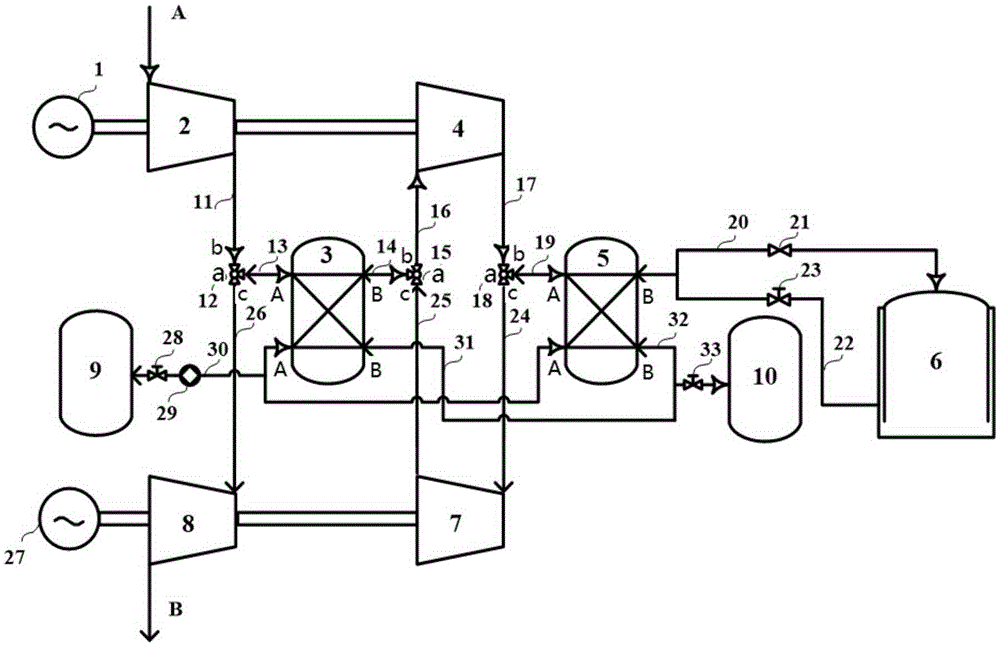

[0032] Such as figure 1 As shown, the novel regenerative compressed air energy storage system of the present invention includes: drive unit 1, compressors 2 and 4, heat exchangers 3 and 5, compressed air storage device 6, expanders 7 and 8, generator 27. Cold tank 9, hot tank 10, three-way reversing valve 12, 15 and 18, pump 29, valves 21, 23, 28 and 33, pipelines 11, 13, 14, 16, 17, 19, 20, 22, 24, 25, 26, 30, 31 and 32.

[0033] Specifically, the novel regenerative compressed air energy storage system of the present invention includes compressor units 2, 4, heat storage system, expansion units 7, 8 and compressed air storage device 6, and the compressor units 2, 4 include at least two-stage compressors, Wherein, the inlet of the first-stage compressor 2 is connected to the air source A, and the last-stage heat exchanger 5 is arranged on the ventilation pipeline between the outlet of the last-stage compressor 4 and the inlet of the compressed air storage device 6, with two a...

Embodiment 2

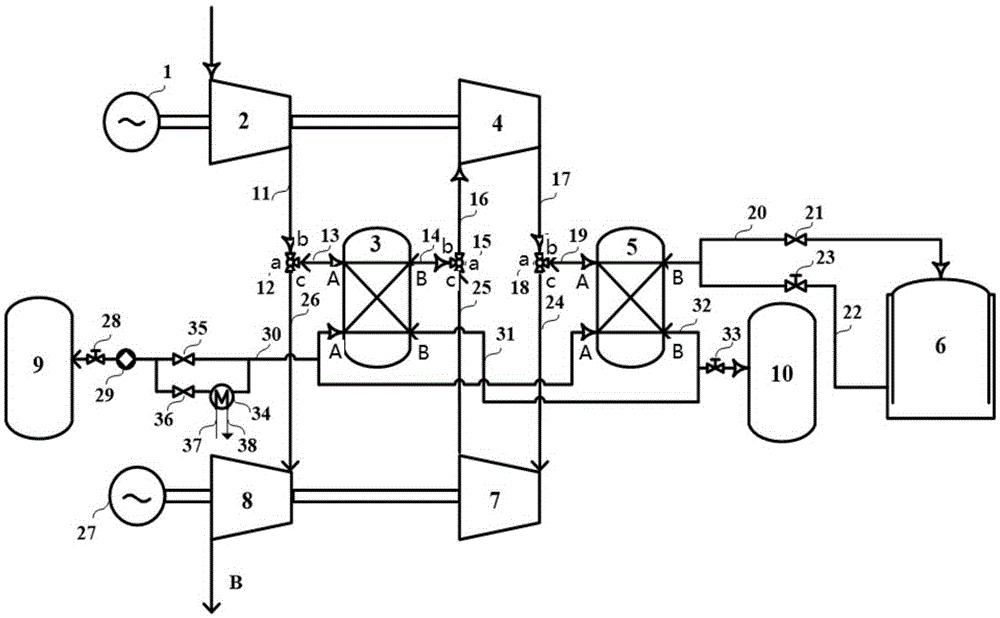

[0045] Such as figure 2 As shown, the main structure of Embodiment 2 of the present invention is the same as that of Embodiment 1, and a cooler 34, valves 35 and 36, and pipelines 37 and 38 connected to the outside world are added. Wherein, during energy storage, valve 36 is closed and valve 35 is opened, and the working process is consistent with Embodiment 1; when energy is released, valve 35 is closed and valve 36 is opened. The temperature of the heat exchange medium coming out of the liquid side enables the cold tank 9 to provide a lower temperature heat exchange medium for the liquid sides of the heat exchangers 3 and 5 during the energy storage stage, further enhancing the heat storage capacity and improving the system efficiency. In addition, the pipelines 37 and 38 connecting the cooler 34 with the outside world can be connected with systems such as heat pumps, so that they can be used for different purposes such as air conditioning and refrigeration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com