Automatic partial pressure double gear pump

A duplex gear pump and gear pump technology, applied in the directions of rotary piston pump, rotary piston/swing piston pump combination, rotary piston/swing piston pump components, etc. Balance, cascade pump life reduction, easy damage and other problems, to achieve long service life, eliminate instantaneous pressure pulse, and close service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

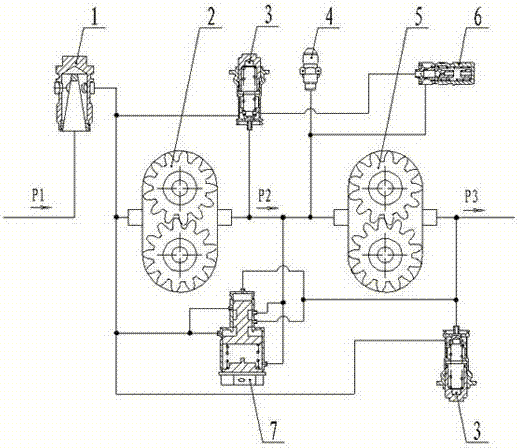

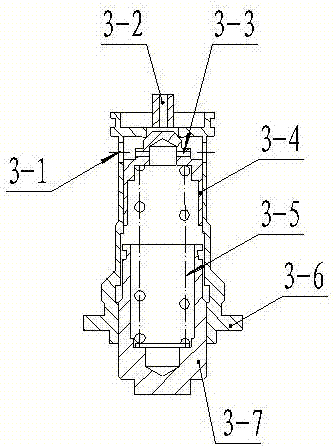

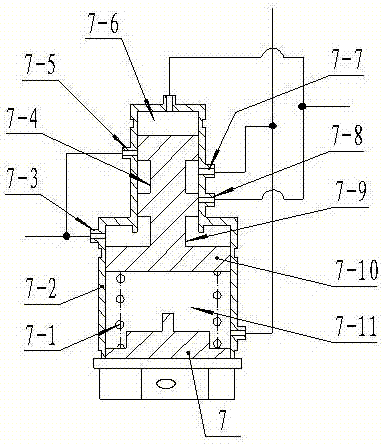

[0012] Such as Figure 1~3 As shown: the first-stage gear pump 2 (that is, the booster pump) is connected in series with the second-stage gear pump 5 (that is, the high-pressure pump); the partial pressure adjustment device 7 is separated by the shell 7-2, which is located in the shell and separates the inside of the shell It is composed of the piston 7-10 of the high-pressure chamber 7-6 and the low-pressure chamber 7-11, and the spring 7-1 that presses the piston tightly in the low-pressure chamber 7-11; there is a first oil port 7-1 on the housing 7-2. 3. The second oil port 7-5, the third oil port 7-7 and the fourth oil port 7-8, the piston 7-10 has a first annular groove 7-4 and a second annular groove 7-9. The first oil port 7-3 and the second oil port 7-5 are respectively connected to the inlet end of the first-stage gear pump 2 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com