Automobile air conditioner blower driven by brushless direct current motor

A technology for brushless DC motors and automotive air conditioners, applied in machines/engines, components of pumping devices for elastic fluids, electric components, etc., can solve the problems of low efficiency, unreasonable heat dissipation structure, carbon Brush and commutator heating and other problems, to achieve the effect of light weight, reliable performance and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

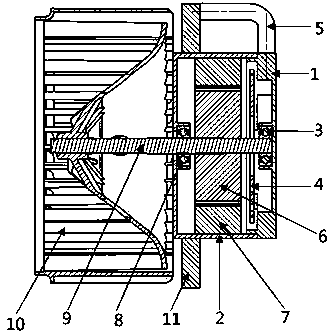

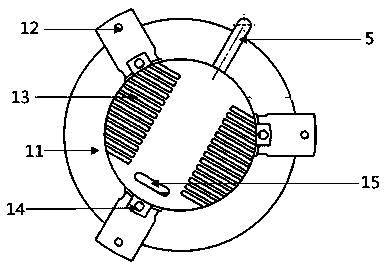

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0025] like figure 1 and figure 2 As shown, an automobile air-conditioning blower driven by a DC brushless motor, including a wind wheel 10 and a DC brushless motor, is driven by a DC brushless motor, cancels the use of carbon brushes and commutators, and the friction force is greatly reduced when the fan is running. Small, smoother operation, lower noise, high efficiency, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com