Clutch of electric power unmanned aerial vehicle

An unmanned helicopter and clutch technology, which is applied to clutches, automatic clutches, mechanical equipment, etc., can solve the problems of affecting the flight safety of electric unmanned helicopters, excessive clearance of the triangular base, loss of power transmission of the clutch, etc. Fracture, good impact resistance, ensure the effect of power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

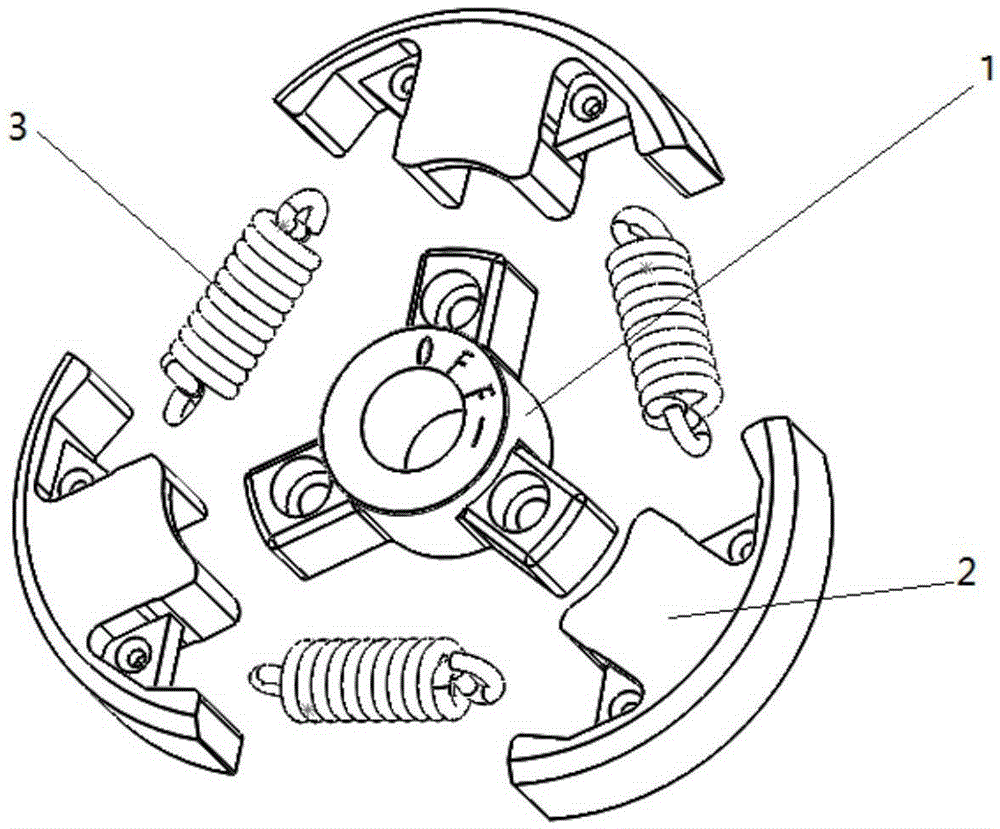

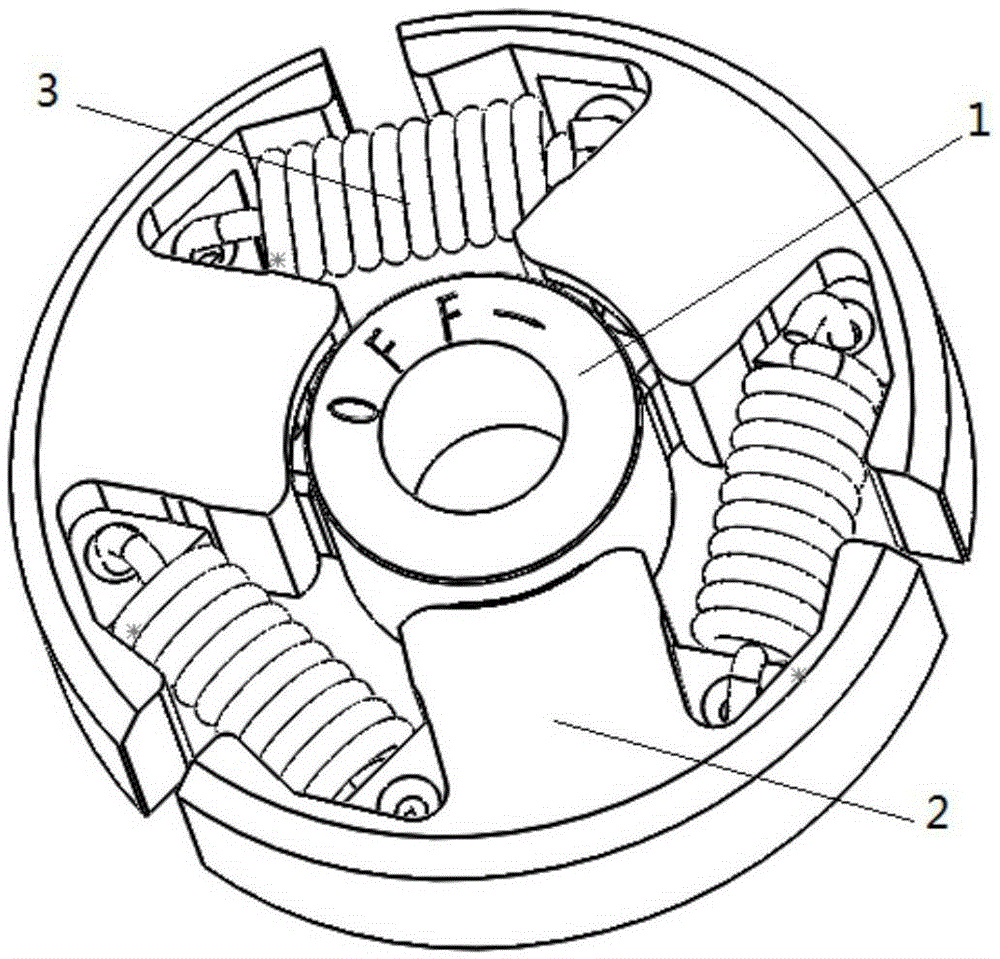

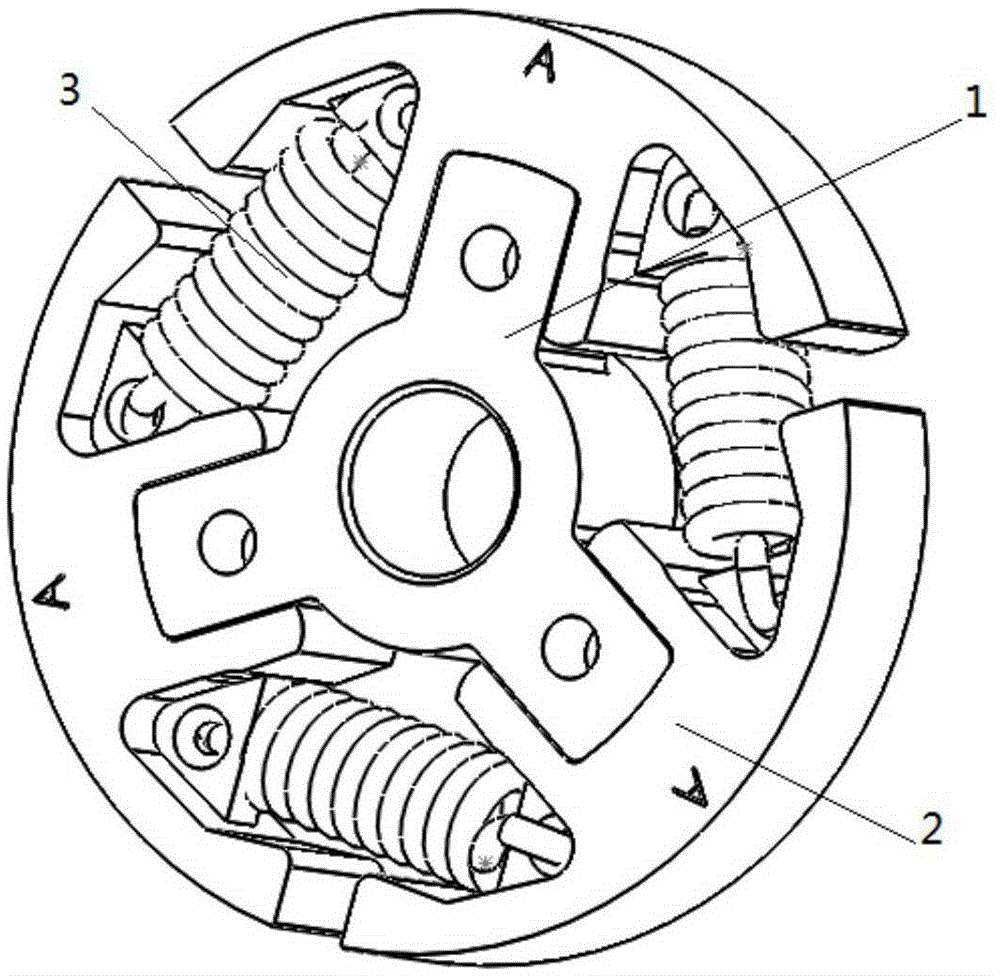

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is an improved clutch for an electric unmanned helicopter, which includes a triangular base 1, a clutch throwing block 2, and a return spring 3. Three fastening bolts 7 are fixed on the driving disk of the engine, and a washer 6 is placed between the fastening bolts and the driving disk of the engine. After tightening the bolts, the same speed as the output shaft of the engine is guaranteed; the three clutch blocks are distributed and installed at 120° On the triangular base; the three clutch throwing blocks rely on three return springs to tighten each other so that the throwing blocks are close to the triangular base; the three clutch throwing blocks and the triangular base are all made of 40Cr material instead of the original powder metallurgy material , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com