Water circulating system for absorbing heat of cooking bench

A technology of water circulation and heat, which is applied in the field of water circulation system, can solve the problems of insufficient energy saving, ineffective use of invalid heat energy, and insufficient constant temperature, etc., to achieve energy saving and environmental protection needs, solve heating demand problems, and improve energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

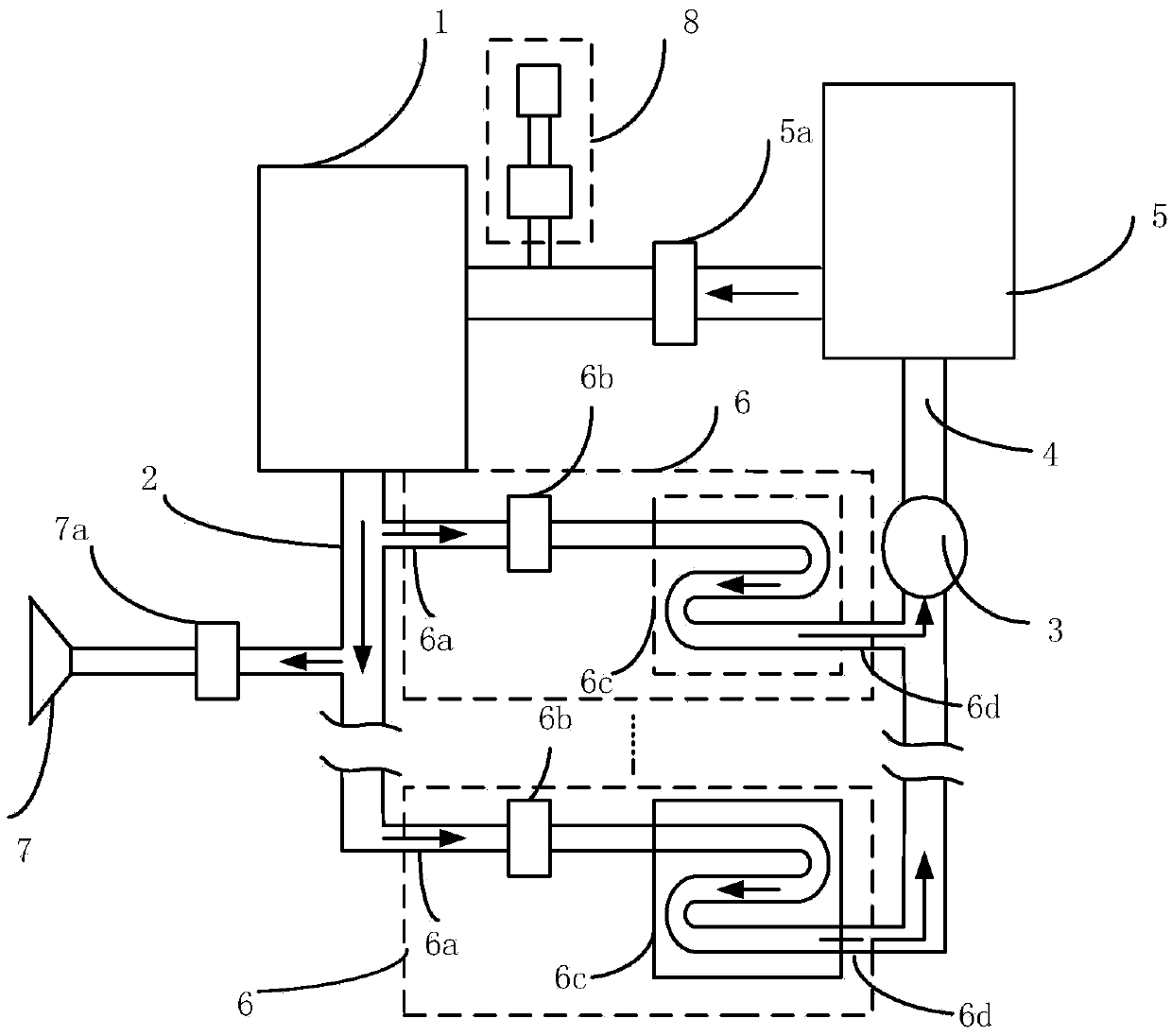

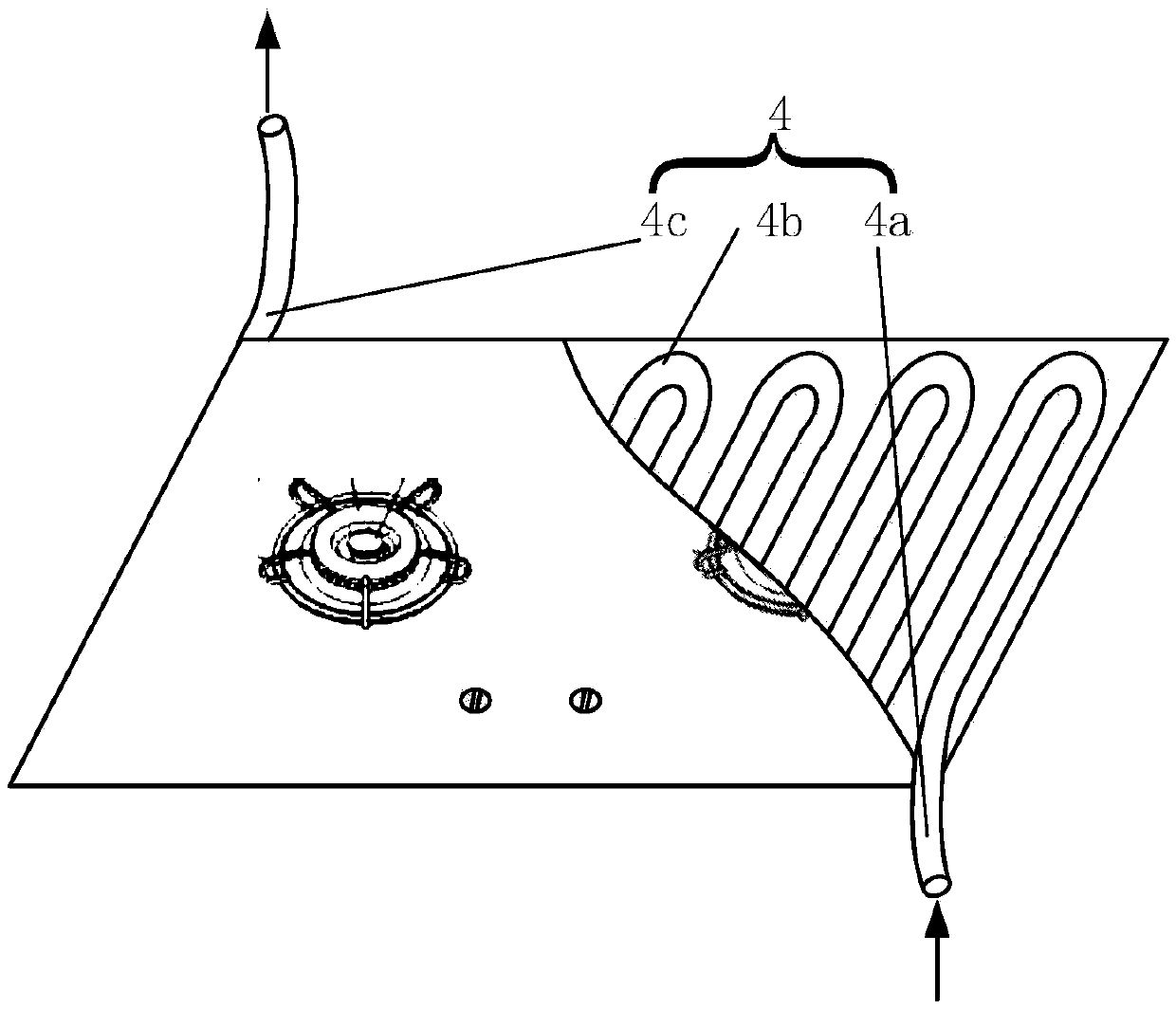

[0011] Such as figure 1 The shown water circulation system for absorbing the heat of the stove includes a water supply module 8 connected to the water inlet of the water heater 1, a hot water output pipe 2 connected to the water outlet of the water heater 1, and the hot water output pipe 2 is connected to a shower head through a manual switch 7a 7. The key point is that at least one heating module 6 is connected to the hot water output pipe 2. The upstream of the heating module 6 is the water inlet pipeline 6a, the midstream is the heat exchange pipeline 6c, and the downstream is the return water pipeline 6d , the return pipes 6d of each heating module 6 flow into the same confluence pipe 4 through the water pump 3 for confluence, and the confluence pipe 4 includes a drain pipe inlet pipe 4a, a drain pipe 4b and a drain pipe outlet pipe 4c, figure 2 It is a partial sectional view of the installation relationship between the manifold 4 and the gas cooker panel, from figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com