Leveling and self-aligning micro-motion workbench

A workbench and work platform technology, applied in the field of precision measurement, can solve the problems of difficulty in meeting the actual needs of the project, insufficient hinge stiffness and strength, and insufficient compact structure, etc., and achieve the effect of compact structure, simple manufacturing process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the present invention is not limited to the following embodiments.

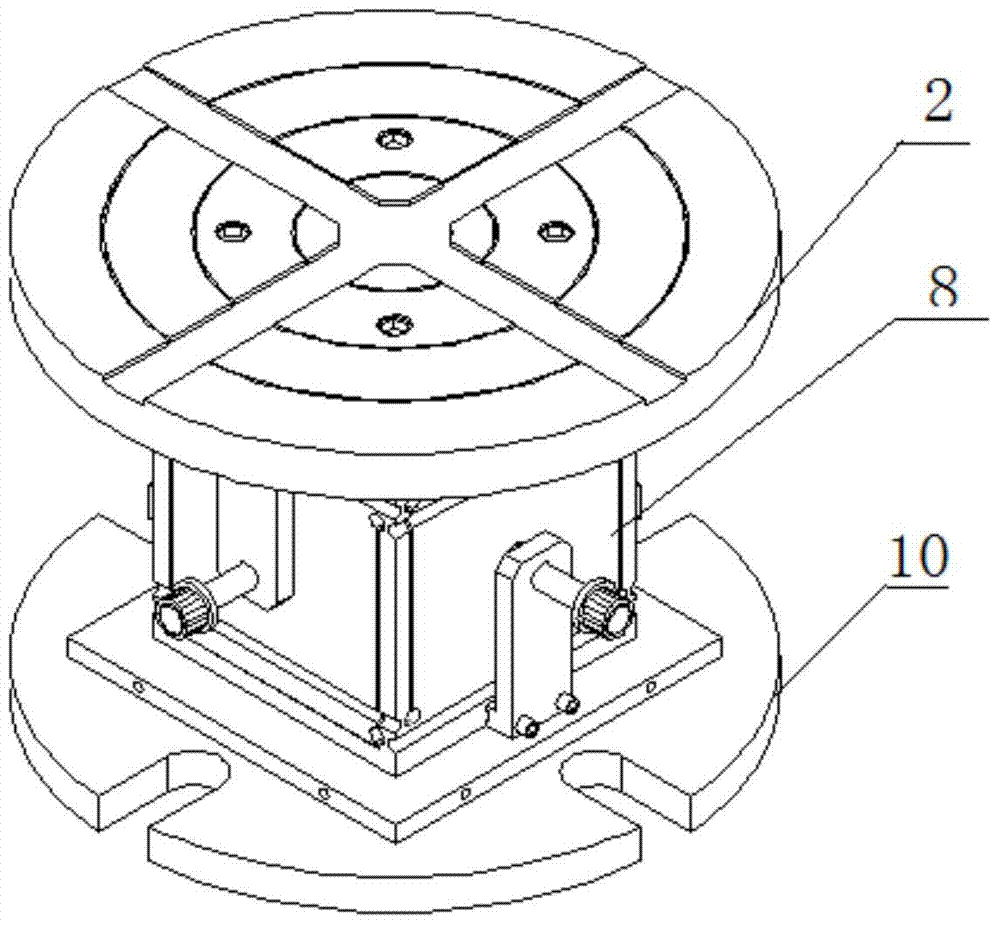

[0038] Such as figure 1 As shown, the leveling and centering micro-motion workbench of the present invention mainly includes a base 10, a leveling and centering body 8 installed on the base 10, and a working platform 2 for placing workpieces. Establish on leveling and centering body 8 and comprise centering mechanism and leveling mechanism.

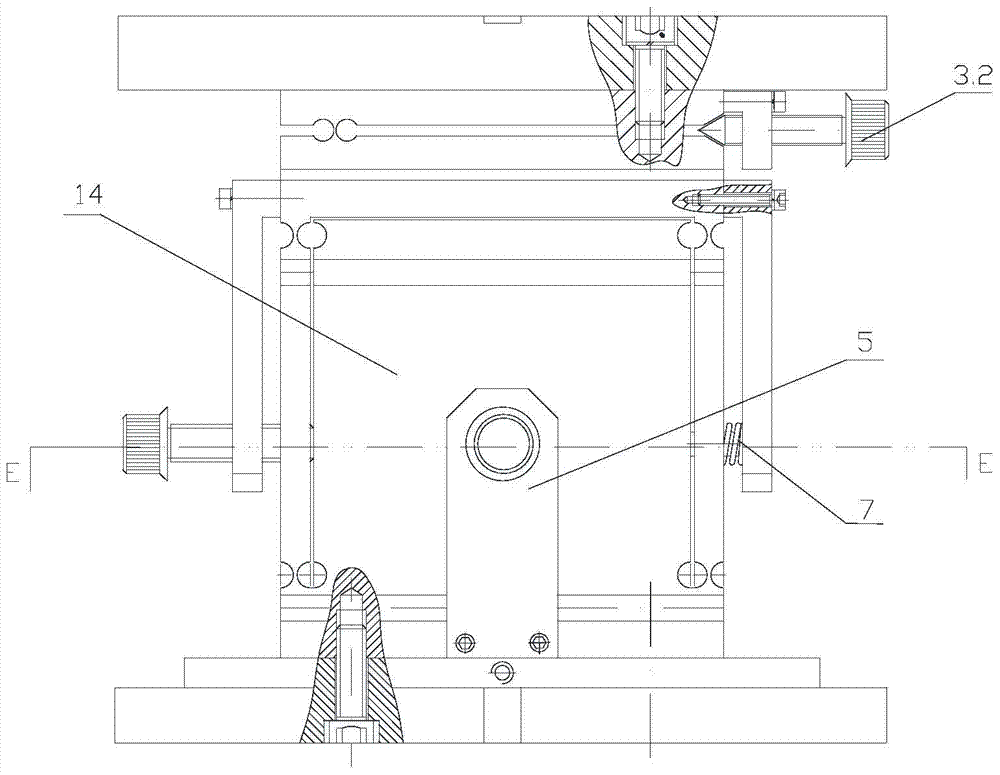

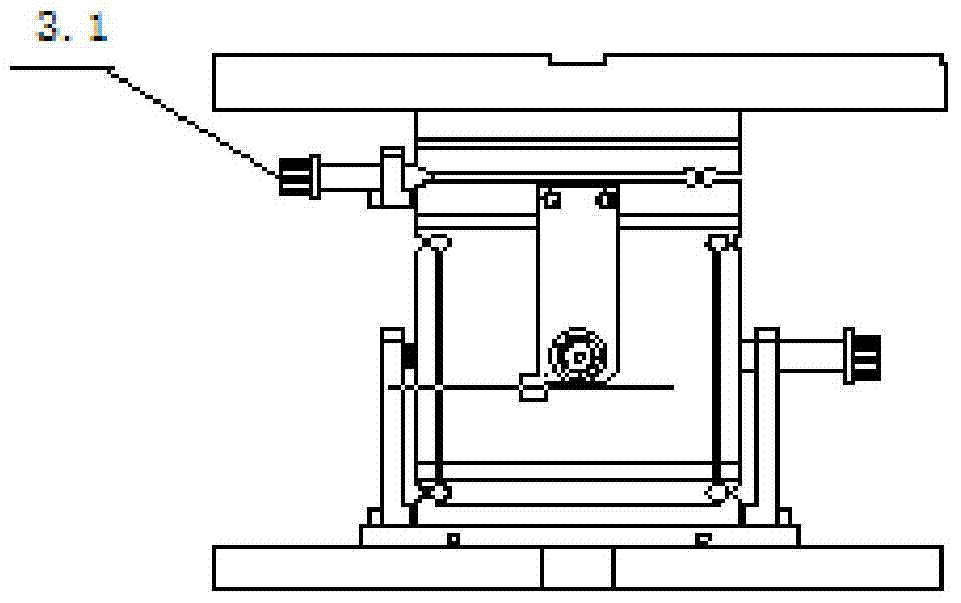

[0039] Such as Figure 2 to Figure 9 , the whole leveling and centering body 8 is formed by wire cutting of a cuboid steel block. The leveling mechanism adopts the four-point leveling principle and the flexible hinge mechanism to realize the leveling function. The leveling mechanism is divided into three layers. The upper layer ① is connected with the working platform 2 where the workpiece is placed by four screws, and the middle laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com