Method for testing anti-cracking performance of asphalt binder

A technology of asphalt binder and anti-crack performance, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems that cannot explain the law of crack crack propagation and cannot accurately characterize the anti-crack performance of asphalt binder. Achieve stable and reliable test results, simple and easy test process, simple and cheap equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

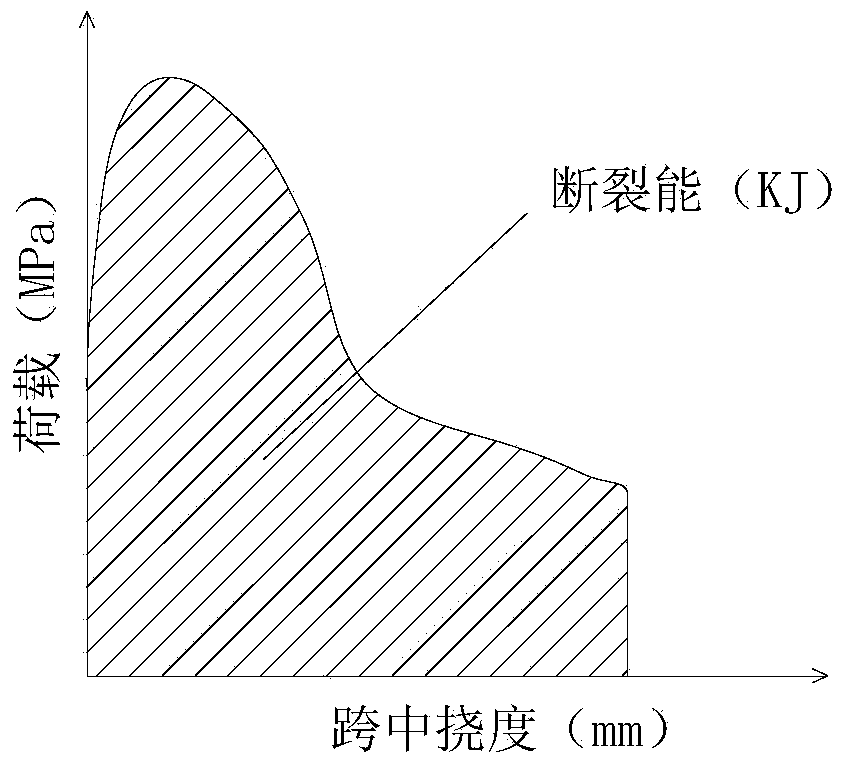

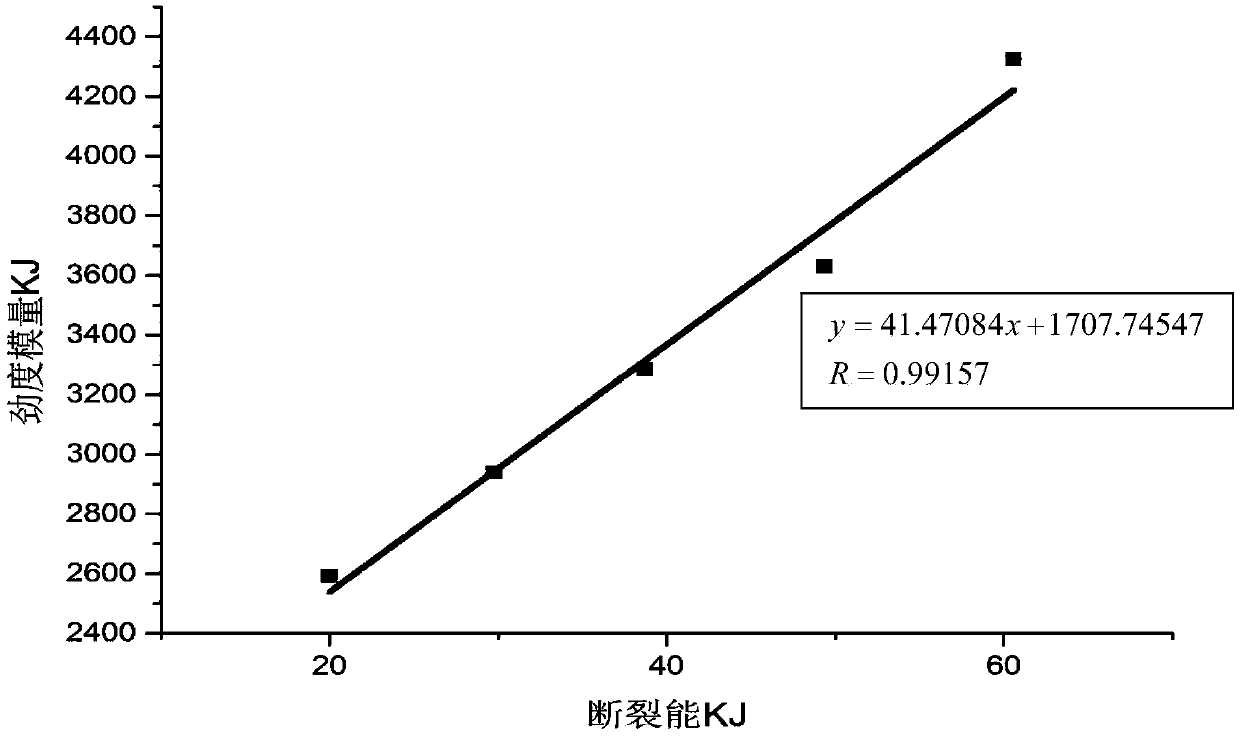

[0023] The test of this embodiment is realized by means of the bending beam creep test instrument (BBR), and the method for specifically testing the crack resistance of asphalt binder consists of the following steps:

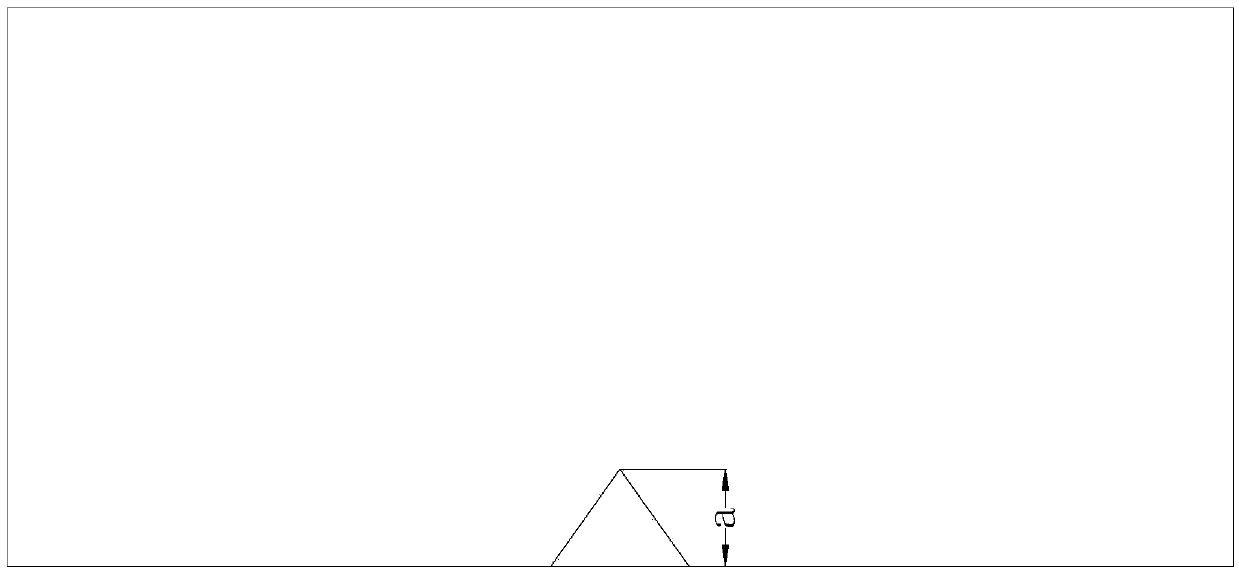

[0024] (1) After the asphalt binder to be tested is slowly heated to a flow state, it is poured into a mold for molding. After the pouring is completed, the mold is cooled at room temperature. When the demoulding condition is reached, the mold is removed and the test piece is transferred out of it. , to obtain a rectangular parallelepiped sample with a cut in the middle of the edge of one side, such as figure 1 As shown, after demoulding, put the sample into a constant temperature bath that reaches the experimental temperature, and keep the temperature at 45°C for 60 minutes.

[0025] In order to ensure the simulation accuracy of the experimental results, the section of the notch is processed into an isosceles triangle with an apex angle of 60°, and the depth a ...

Embodiment 2

[0034] In this example, step (1) is to slowly heat the asphalt binder to be tested to a fluid state, then pour it into a mold for molding, and after pouring is completed, place the mold at room temperature to cool, and when the demoulding condition is reached, remove the mold , transfer the test piece out of it, and obtain a cuboid sample with a cut in the middle of the edge on one side. After demoulding, put the sample into a constant temperature bath that reaches the experimental temperature, and keep it at a constant temperature within 0°C for 65 minutes; in this example, the cut The cross-section is processed into an isosceles triangle with a vertex angle of 58°, and the depth a of the incision and the height w of the sample satisfy: a / w=1 / 10.

[0035] Step (2) is: use a bending beam creep test instrument to perform a single edge bending rheological experiment on the sample, a displacement sensor is arranged in the cutout of the sample, and a hydraulic loading device is use...

Embodiment 3

[0038] Step (1) of this embodiment is to slowly heat the asphalt binder to be tested to a fluid state, then pour it into a mold for molding, after pouring is completed, place the mold at room temperature to cool, and when the demoulding condition is reached, remove the mold, Transfer the test piece out of it to obtain a cuboid sample with a cut in the middle of the edge on one side. After demoulding, put the sample in a constant temperature bath that reaches the experimental temperature, and keep it at 60°C for 55 minutes. The cross-section of the notch is processed into an isosceles triangle with an apex angle of 62°, and the depth a of the notch and the height w of the sample satisfy: a / w=1 / 15.

[0039] Step (2) is to use a bending beam creep test instrument to perform a single-edge bending rheological experiment on the sample. A displacement sensor is arranged in the cutout of the sample, and a hydraulic loading device is used to test the middle part of the sample on the oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com