Supercharging system integrated steel pipe hydrostatic testing machine water-filling apparatus

A technology of hydraulic testing machine and pressurization system, which is applied in the direction of applying stable tension/pressure to test material strength, liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problem of difficult increase of pressure test pressure and production efficiency Low cost, high operating cost and other issues, to achieve the effect of reducing leakage points, low cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

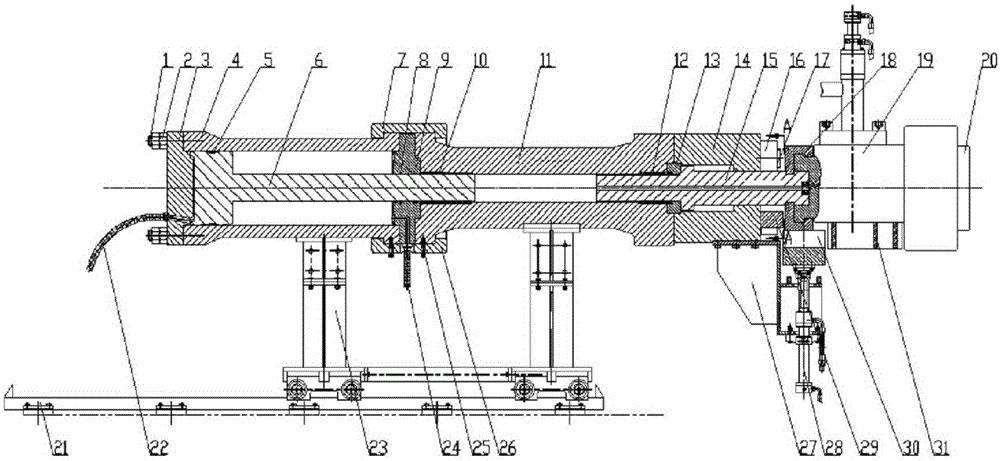

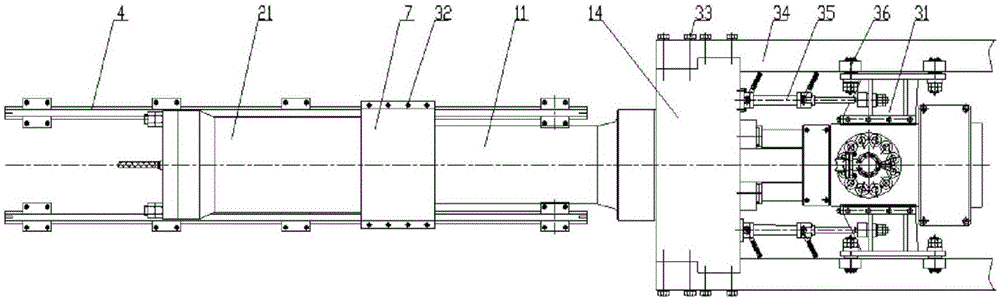

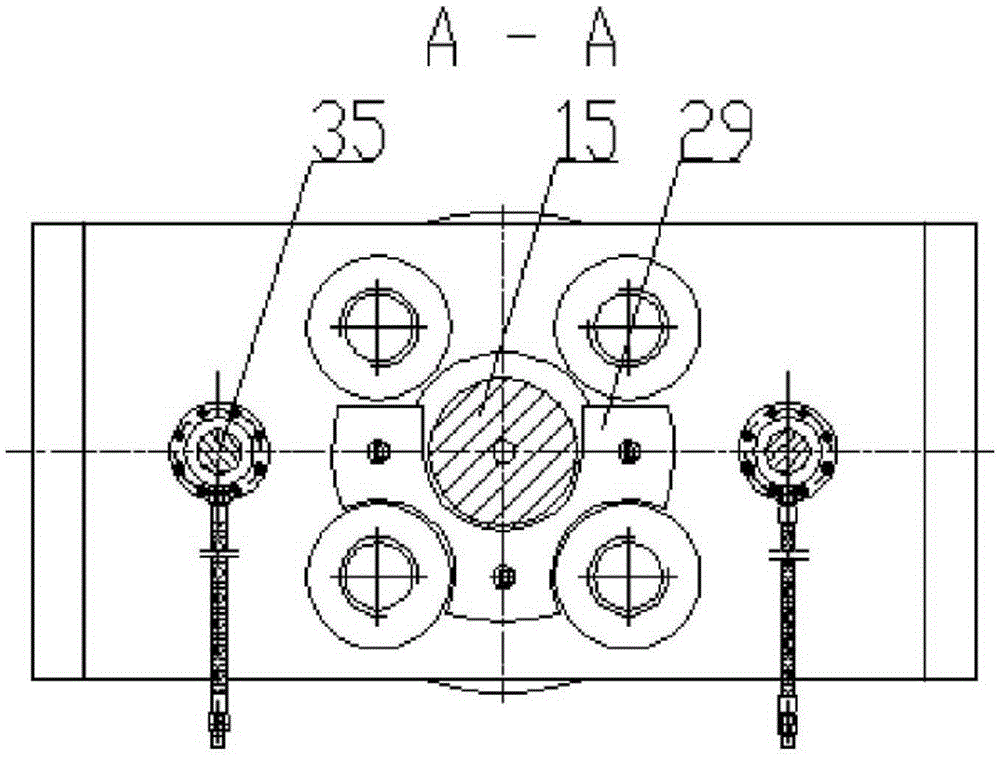

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] refer to figure 1 , figure 2 , image 3 , a pressurization system integrated steel pipe hydraulic testing machine water filling device, including a gland 3, the gland 3 is connected to the low-pressure cylinder 4 through the first stud 1 and the first nut 2, and the gland 3 is equipped with an oil inlet Pipeline 22; low-pressure cylinder 4 is equipped with piston rod 6, and the end of piston rod 6 is equipped with combined seal 5, which can prevent the oil on both sides of piston rod 6 from communicating; low-pressure cylinder 4 is also connected to the inside of cylinder connecting block 9 One end of the guide ring 8 and the other end of the guide ring 8 are connected to the high-pressure cylinder 11, and an oil return pipeline 24 is installed in the middle of the guide ring 8; the upper connecting gland 7 and the lower connecting gland 26 connect the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com