Bidirectional transient voltage suppression device

A transient voltage suppression and device technology, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems that the electrostatic protection ability of the device cannot be fully exerted, the failure of the ESD protection device, and the small discharge current of the device, etc., to achieve The effect of improving electrostatic discharge capacity, increasing maintenance voltage, and increasing device area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

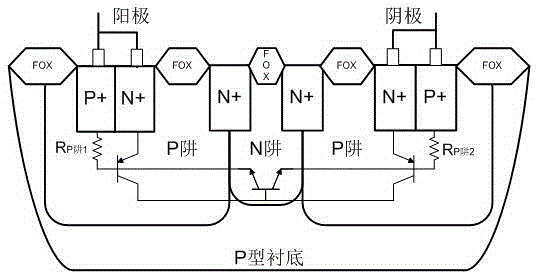

[0021] Such as Figure 5 As shown, the bidirectional transient voltage suppression device of the present invention includes five layers, wherein the bottom layer is a P-type substrate 100; the second layer is an N-type deep well 200 arranged on the P-type substrate 100; the third layer is formed on The first P well 301 and the second P well 302 on the N-type deep well 200; the fourth layer is the first N well 402 formed on the N-type deep well, and the second N well 401 formed in the P well 301, The third N well 403 formed in the P well 302; the fifth layer is six heavily doped regions: in the first P well 301, from left to right are the first P+ implantation region 501 and the first N+ implantation region 502 , the second N+ implantation region 503, wherein the second N+ implantation region 503 straddles the first P well 301 and the N well 401, and the left boundary of the second N+ implantation region 503 is flush with the left boundary of the second N well 401; the second P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com