Pipe components and methods of manufacture

A technology of riser components and flexible pipes, applied in the direction of pipes/pipe joints/fittings, drill pipes, casings, etc., can solve problems such as large oscillation motion, failure of standpipe system, etc., to prolong life and suppress vortex-induced vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

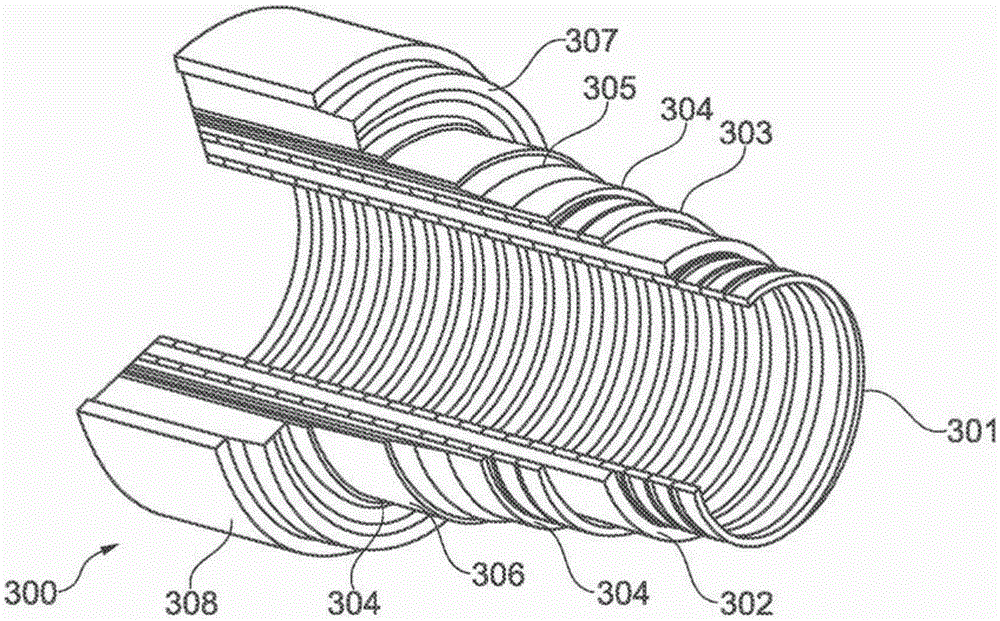

[0040] Throughout this specification reference is made to flexible pipe. It should be understood that flexible pipe is an assembly of a portion of a pipe body and one or more end fittings in each of which a respective end of the pipe body terminates. image 3 It is shown how the tube body 300 is formed from a combination of layered materials forming a pressurized conduit according to an embodiment of the present invention. although image 3 Some specific layers are shown in , but it should be understood that the invention is broadly applicable to coaxial pipe body structures comprising two or more layers fabricated from a wide variety of possible materials. It should be further noted that layer thicknesses are shown for illustrative purposes only.

[0041] Such as image 3 As shown, the tube body includes an optional carcass layer 301 . The carcass provides an interlocking construction that can be used as the innermost layer to fully or partially prevent rupture of the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com