Fresh air system

A fresh air and air filter technology, applied in the direction of charging system, fuel air filter, fuel air intake, etc., can solve the problems of laborious, complicated replacement of filter elements, and complicated structure of fresh air system, etc. Simple structure, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

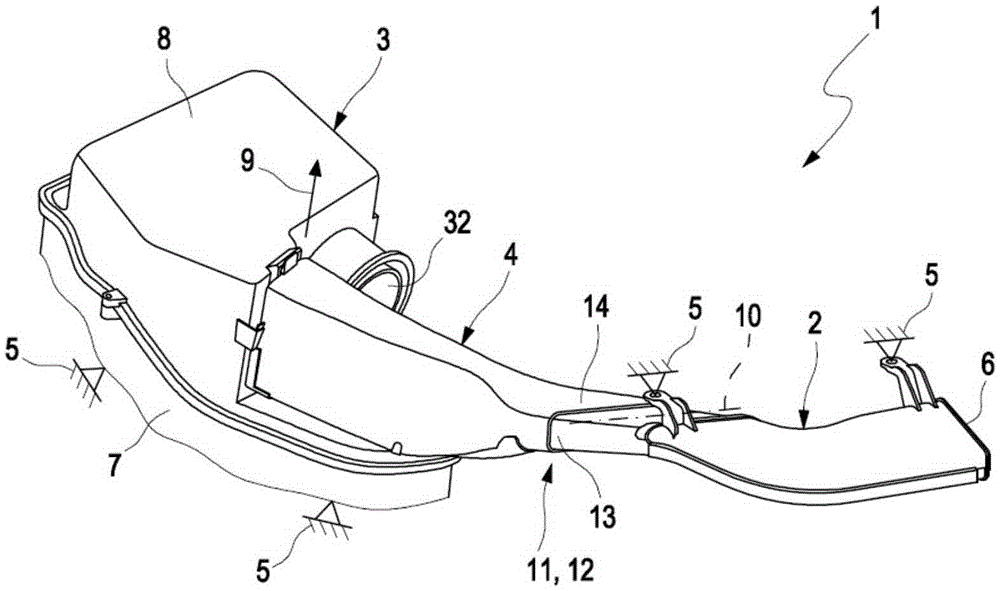

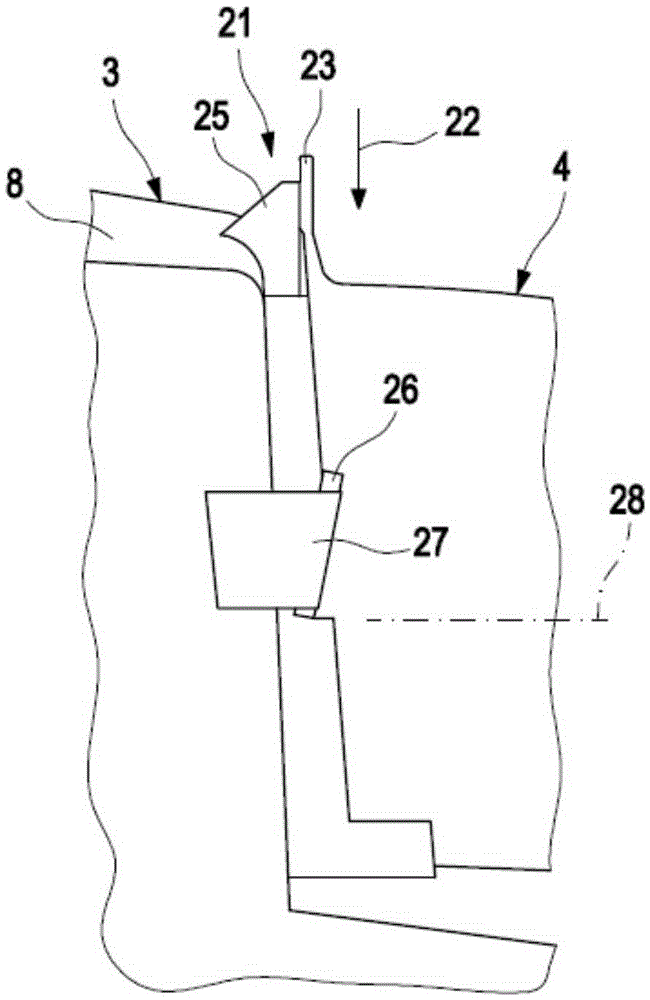

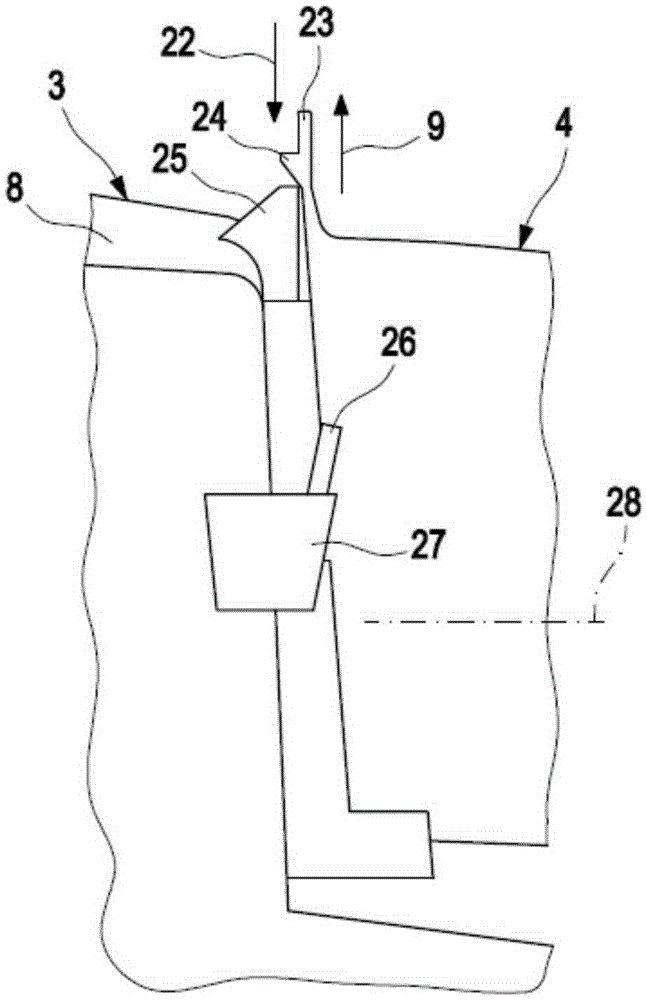

[0037] according to Figures 1 to 8 , a fresh air system 1 of which only a part is shown here, which is used to supply fresh air to the combustion chamber of an internal combustion engine (not shown here) when installed, the fresh air system 1 comprises an inlet section 2, an air filter 3 and Connect segment 4.

[0038] In the installed state, the inlet section 2 is fixedly connected to the periphery 5 of the internal combustion engine (indicated here only symbolically). Typically, the internal combustion engine is arranged in the engine compartment of the vehicle, so that the periphery 5 can be represented by an attachment point inside said engine compartment. The inlet section 2 has an inlet opening 6 through which fresh air can enter the fresh air system 1 from the environment. In this case the inlet opening 6 can in principle open directly to the environment. It is also possible that the inlet opening 6 can adjoin a correspondingly shaped air inlet (not shown here).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com