Environment-friendly medical sterilizing system

A sterilization system and environmentally friendly technology, applied in the field of medical waste treatment, can solve the problems of poor sterilization effect, failure to achieve sterilization, high cost, etc., to avoid the possibility of secondary contact, save simple structure, and thoroughly classify sterilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, invention is described in further detail.

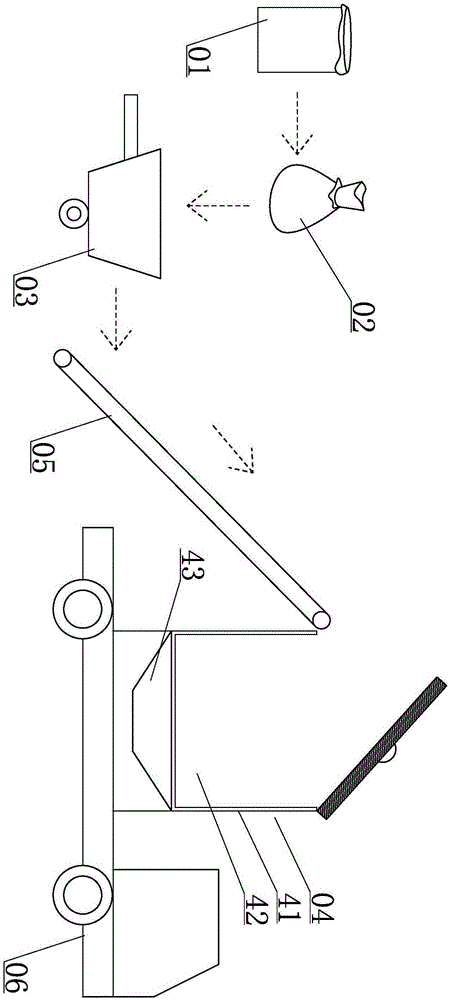

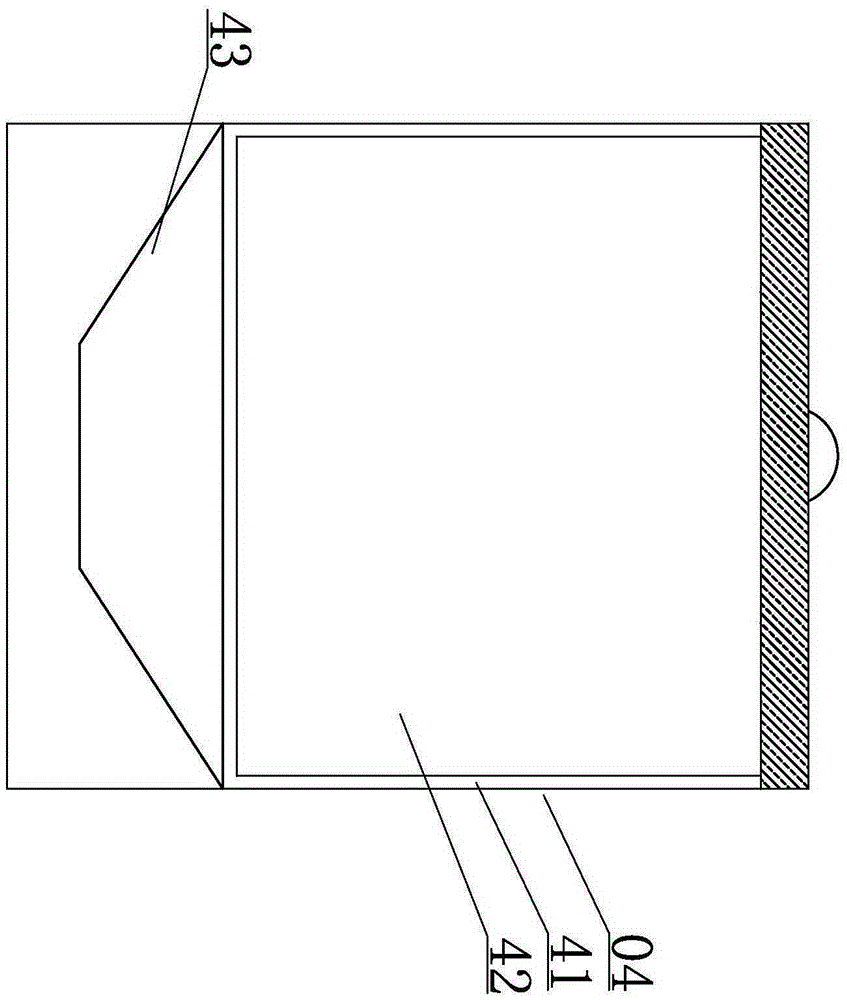

[0013] like Figure 1-2 As shown, an environmentally friendly medical sterilization system includes a collection barrel 01, a non-imitation cloth bag 02 for collecting medical waste and a trolley 03 for transferring a plurality of non-imitation cloth bags 02 filled with medical waste, And the sterilizer 04 that cooperates with the trolley 03 to transport a plurality of non-imitation cloth bags 02 inside for sterilization. The sterilizer 04 includes a housing 41 , a vacuum heating container 42 containing a plurality of non-imitation cloth bags 02 and a high-temperature heating furnace 43 provided on the vacuum heating container 42 . The temperature in the vacuum heating vessel 42 is 250°C-290°C, preferably 270°C. It also includes a carburetor provided on one side of the sterilizer 04. Between the dolly 03 and the vacuum heating container 42, a conveyor belt 05 is arranged to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com