Static mixing device for oil and alkaline and method for using cotton-seed mixed oil to prepare cotton-seed refined oil by using same

A static mixing device and technology for mixing oil, applied in fluid mixers, mixers, separation methods, etc., can solve the problems of solvent volatilization, high safety, and high energy consumption, avoiding volatilization, high mixing efficiency, and reducing power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

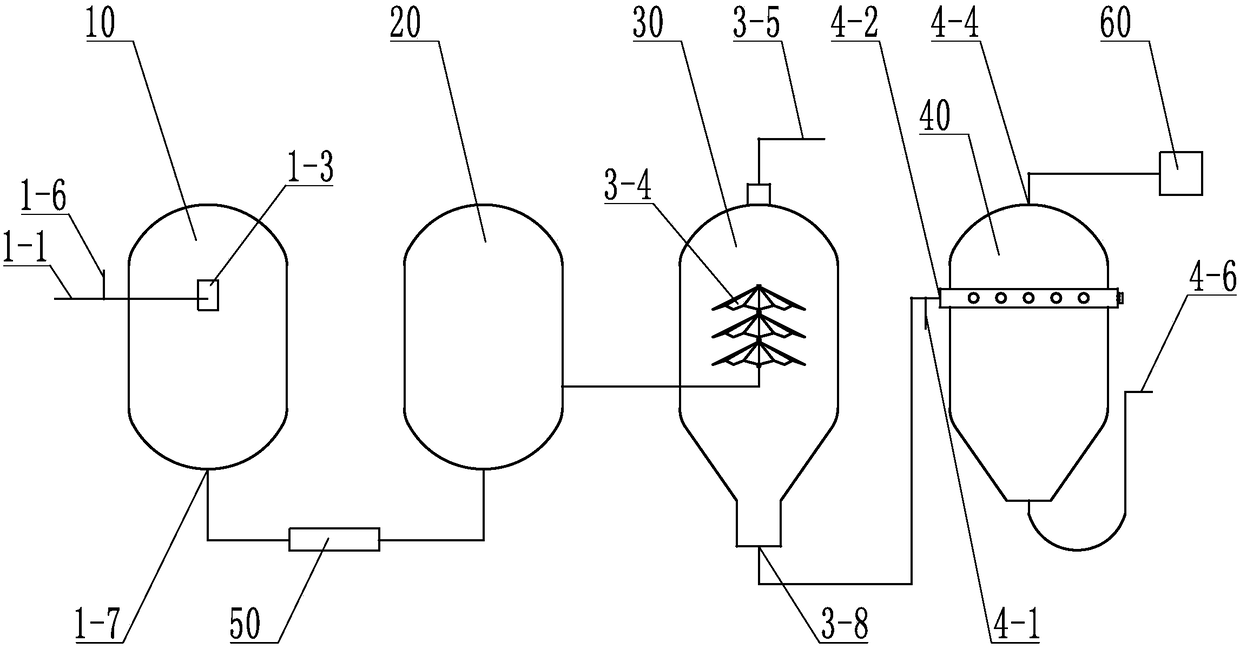

[0058] Embodiment 1: This embodiment discloses a method for refining cottonseed mixed oil, which is characterized in that it at least includes an oil-alkali mixing step. The oil-alkali mixing step is to mix cottonseed mixed crude oil with lye, and then heat for alkali refining after mixing , When mixing, use an oil-alkali static mixing device, and then heat the alkali refining.

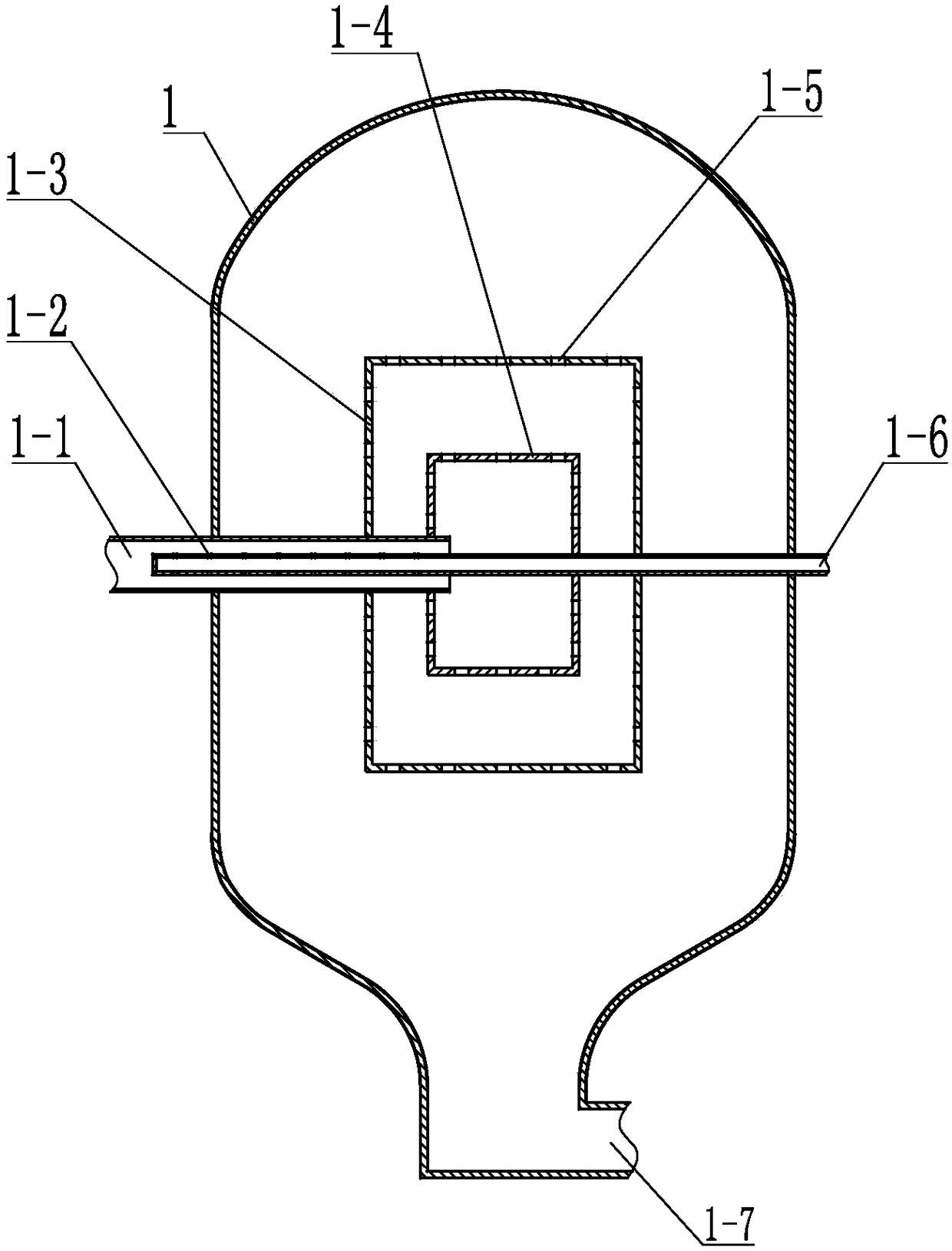

[0059] The oil-alkali static mixing device comprises a tank body A (1), a mixed oil inlet pipe (1-1), an alkali liquor inlet pipe (1-6) and a mixing chamber B (1-4), and the mixing chamber B (1 -4) Set in the tank body A (1), the shell surface of the mixing chamber B (1-4) is provided with a mixed solution seepage hole (1-5), the mixing chamber cavity and the tank body A (1) The inner cavity is communicated through the mixed liquid seepage hole (1-5), the outlet end of the mixed oil inlet pipe (1-1) is placed in the mixing chamber cavity, and at least one section of the lye inlet pipe (1-6) is placed ...

Embodiment 2

[0067] Embodiment 2: This embodiment discloses a method for refining cottonseed mixed oil, which is characterized in that it includes at least a saponin separation step, which is to separate the liquid obtained after the cottonseed mixed oil is refined by alkali, and the saponin separation step Soap and oil are separated by a soap separation device, and the separated oil and soap are collected separately.

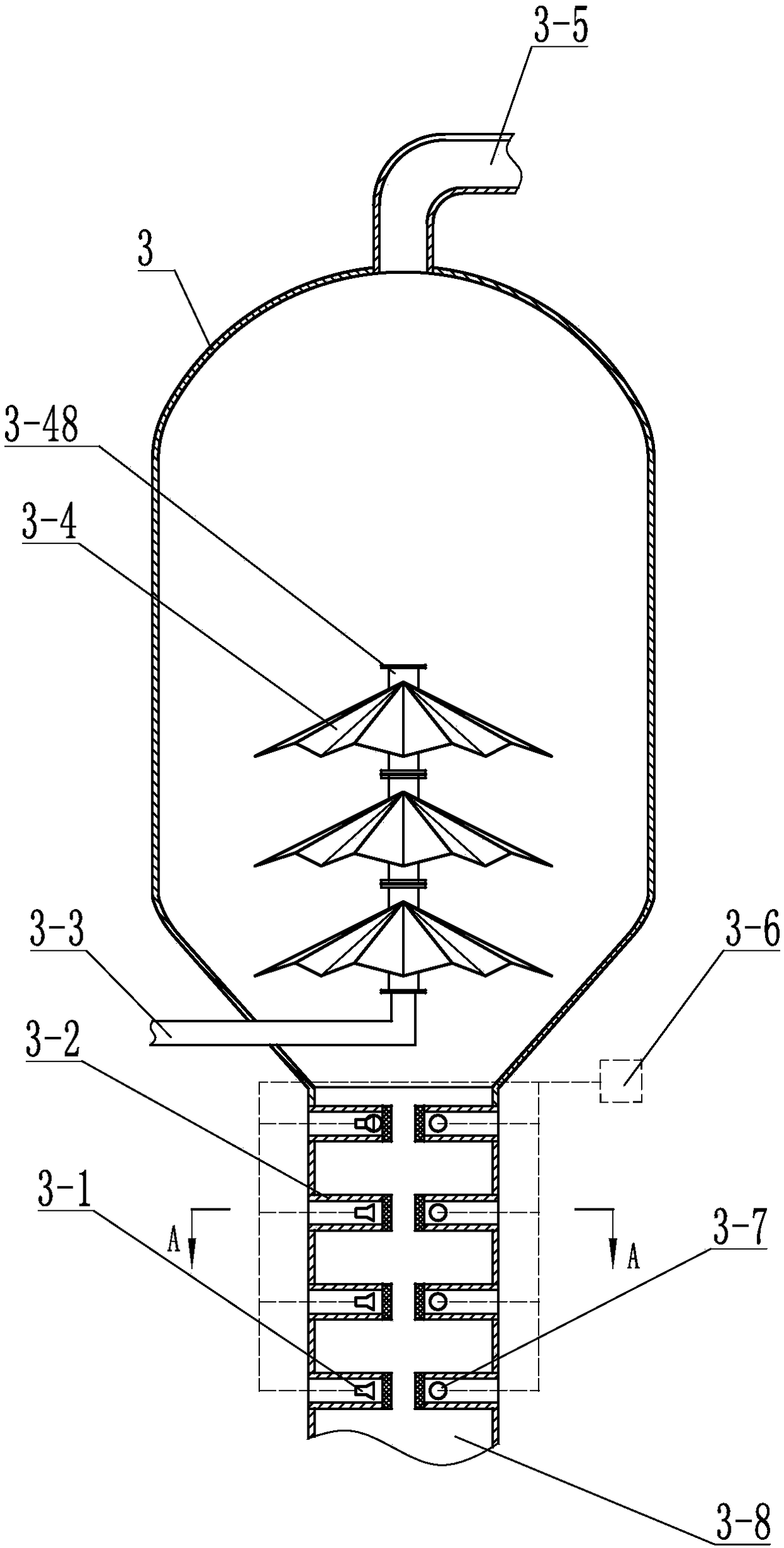

[0068]Said saponin separation device comprises a tank body B (3), said tank body B (3) is provided with an oil outlet (3-5), a saponin discharge pipe (3-8) and a material inlet (3-3) , the oil outlet (3-5) is located at the top of the tank B (3), the saponin discharge pipe (3-8) is located at the bottom of the tank B (3), the oil outlet (3-5) and the drain There is at least one set of soap oil separation discs (3-4) between the soap tubes (3-8), the material inlet (3-3) is connected with the soap horn separation disc (3-4), and the material inlet (3-4) 3) The liquid that e...

Embodiment 3

[0089] Embodiment 3: This embodiment discloses a method for refining cottonseed mixed oil, which is characterized in that: it at least includes a saponin desolventization step, and the saponin desolventization step is to perform desolventization treatment on the soapy liquid obtained in the saponin separation step, And recover the solvent in the desolventization step, the desolventization step uses a saponin desolventization device to perform desolventization, and recover the solvent and saponin.

[0090] Described saponin desolventizing device comprises tank body C (4), and described tank body C (4) top is provided with solvent steam outlet (4-4), and the bottom is provided with saponin discharge pipe (4-6), and described The tank body C (4) is provided with a heating and mixing device,

[0091] The heating and mixing device comprises: a liquid inlet pipe (4-2), a steam inlet (4-1) and an outer cover (4-3) containing dissolving saponin, and the outer cover (4-3) is sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com