Plastic logistics tray provided with stress pieces

A stress sheet, plastic technology, applied in the direction of measuring force, rigid container, measuring device, etc., can solve the problems of damage to the deep structure of the plastic logistics tray, complicated detection process, stress change detection, etc., to improve the detection speed and efficiency, and simplify the detection. Process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Referring to the accompanying drawings, the present invention will be described in detail below.

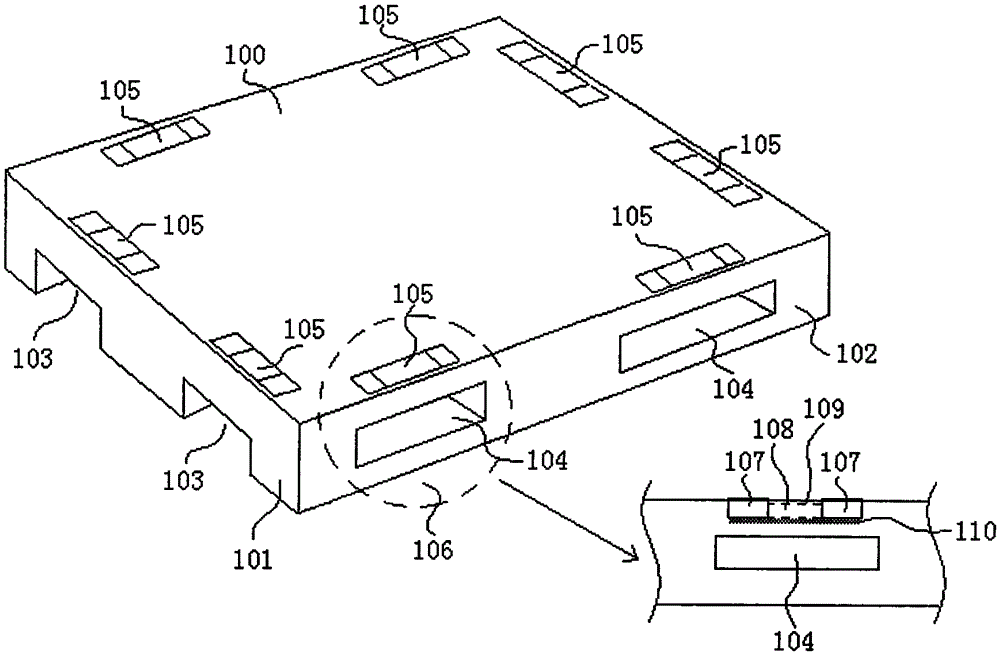

[0015] Such as figure 1 As shown, the structure diagram of a plastic logistics tray with its own stress sheet in the present invention, the plastic logistics tray 100 is a double-entry double-fork structure, and there are two slots 103 at the bottom of the plastic logistics tray 100 from the side 101 of the Chuan shape. The position where the fork arm is inserted during forklift operation, and the two slots 103 run through the bottom of the plastic logistics pallet 100, showing a symmetrical structure, and the fork arm of the forklift can be inserted from any Chuan-shaped side 101;

[0016] There are two jacks 104 at the bottom of the plastic logistics tray 100 from the side 102 of the Japanese shape, which are the positions where the fork arm is inserted when the automatic shuttle machine is in operation, and the two jacks 104 run through the plastic logistics tray 100, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com