Steel ball continuous emission device for ball grinder impact detection

A technology of launching device and ball mill, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problems of high cost, bulky, high launch speed and difficult to control, and achieve simple structure, convenient installation, and device The effect of the right size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

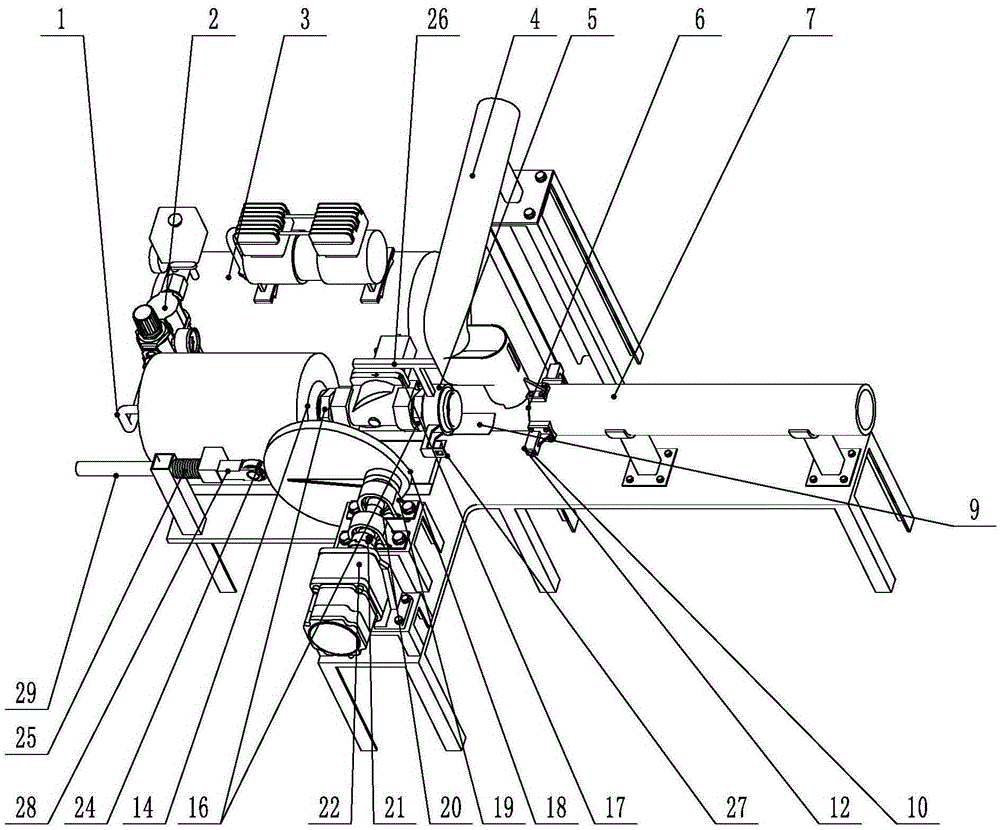

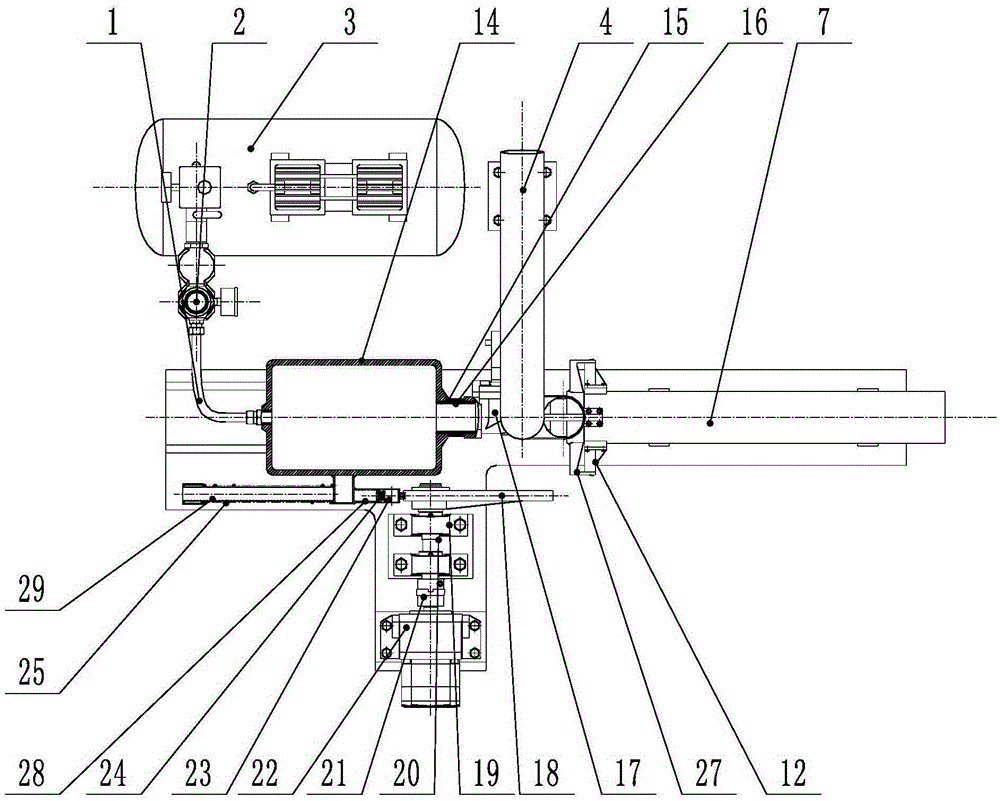

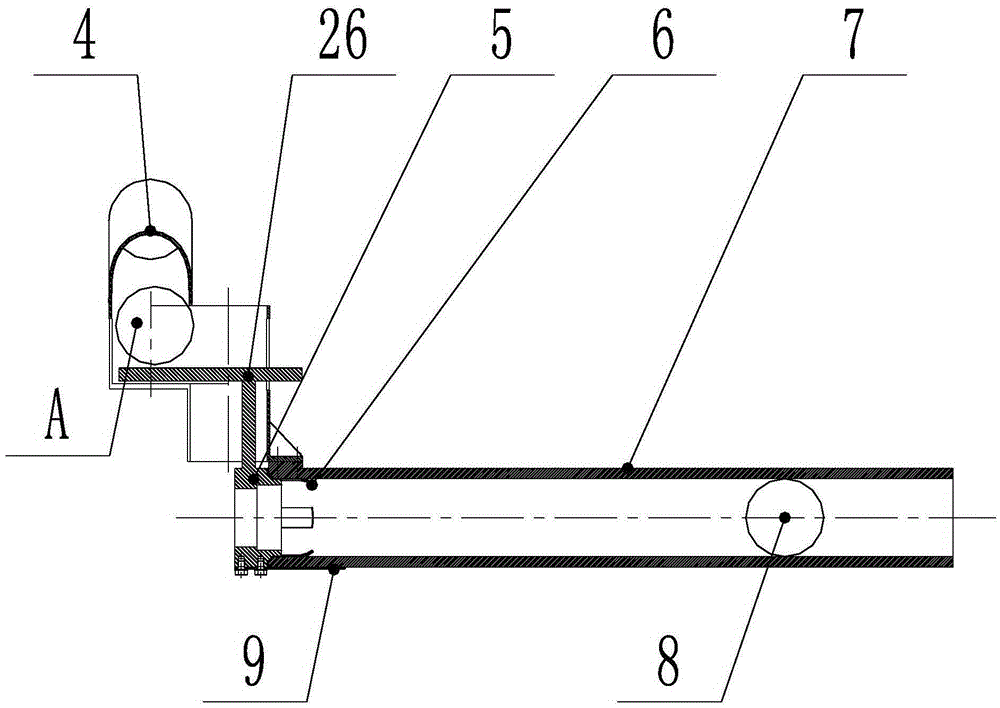

[0023] refer to Figure 1-Figure 5 , the present invention is used for the continuous impact launching device of ball mill impact friction test, comprises air compressor 3, decompression valve 2, air chamber 14, goal pipe 4, gun bore 7 and cam mechanism, and air chamber 14 is connected by flexible pipe 1 The pressure reducing valve 2 is connected to the air outlet of the air compressor 3, the air outlet of the air chamber 14 is connected to the electromagnetic shut-off valve 17 through the external thread pipe joint 16, and the electromagnetic shut-off valve 17 is connected to the external thread pipe joint 16 is connected with the inlet end plate 5, and the electromagnetic shut-off valve 17 is used to control the closing and opening of the air outlet of the air chamber 14, wherein: use the external threaded pipe joint 16 to connect to realize the pneumatic passage, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com