Ultrasonic guided wave transducer that can be built into the inspection pipeline

A technology for guiding ultrasonic waves and detecting pipelines, which is applied in pipeline systems, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It is inconvenient to place the probe on the outer surface of the profile, and the detection efficiency is low, so as to achieve the effects of adjustable pressure, high sensitivity, and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings. Obviously, this is an embodiment of the present invention but not limited thereto. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without making creative efforts belong to the protection scope of the present invention.

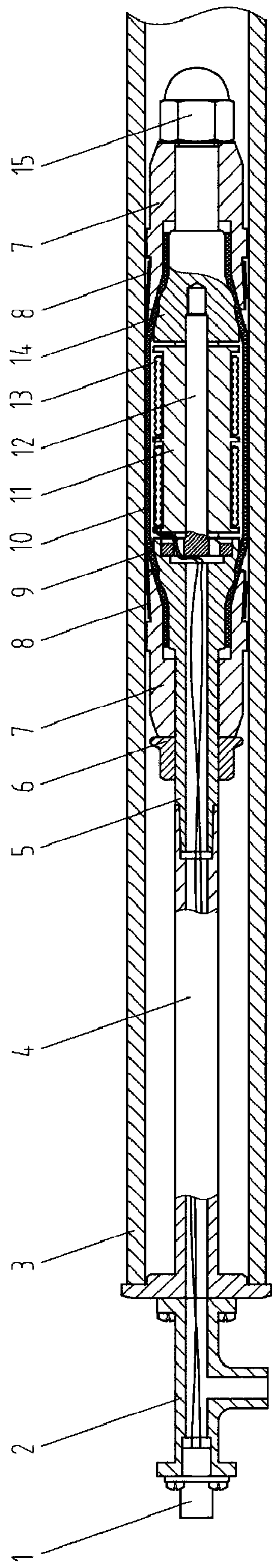

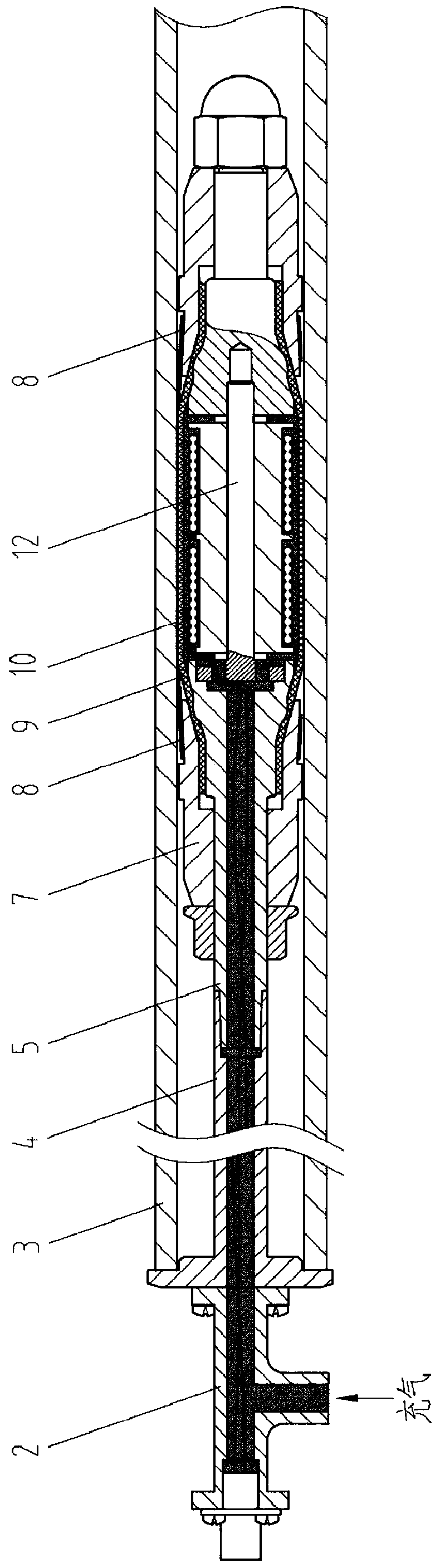

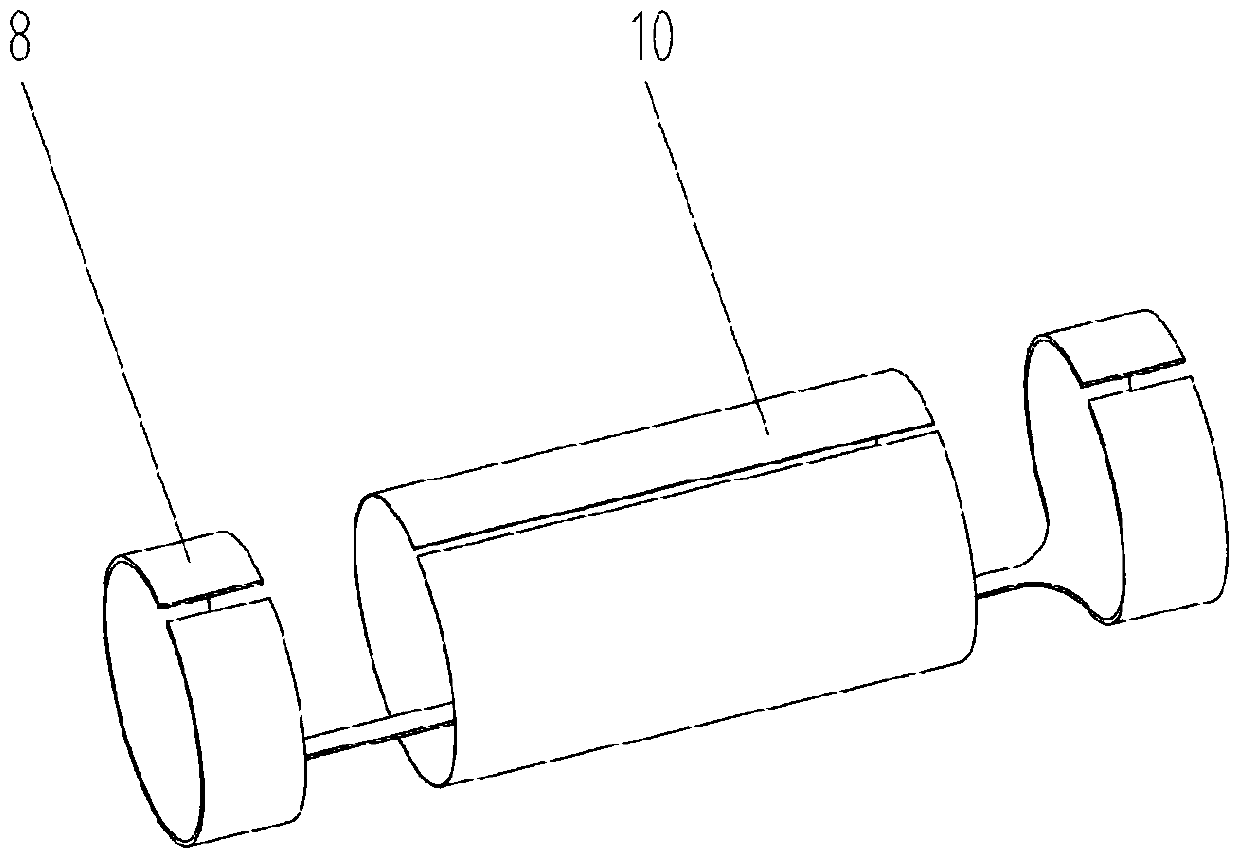

[0027] Such as figure 1 As shown, the present invention includes a connector 1 connected in sequence, an electrical separation tee 2 and a connecting pipe 4, and an ultrasonic guided wave transducer mechanism connected at the end of the connecting pipe 4 and extending into the metal pipe 2 to be detected. The wave transducing mechanism includes a magnetic coil structure and a magnetostrictive strip 10 . The magnetostrictive strip 10 is used to generate and receive guided waves. A permanent magnet is used to magnetize the strip in the axial direction, leaving residual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com