Reflection electrode structural member and ion source

A technology for reflecting electrodes and structural parts, applied in the field of ion sources, can solve the problems of reduced plasma generation efficiency, reduced electron reflection efficiency, etc., and achieve the effects of improving metal aluminum ionization efficiency, compact reflecting electrode structural parts, and increasing ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

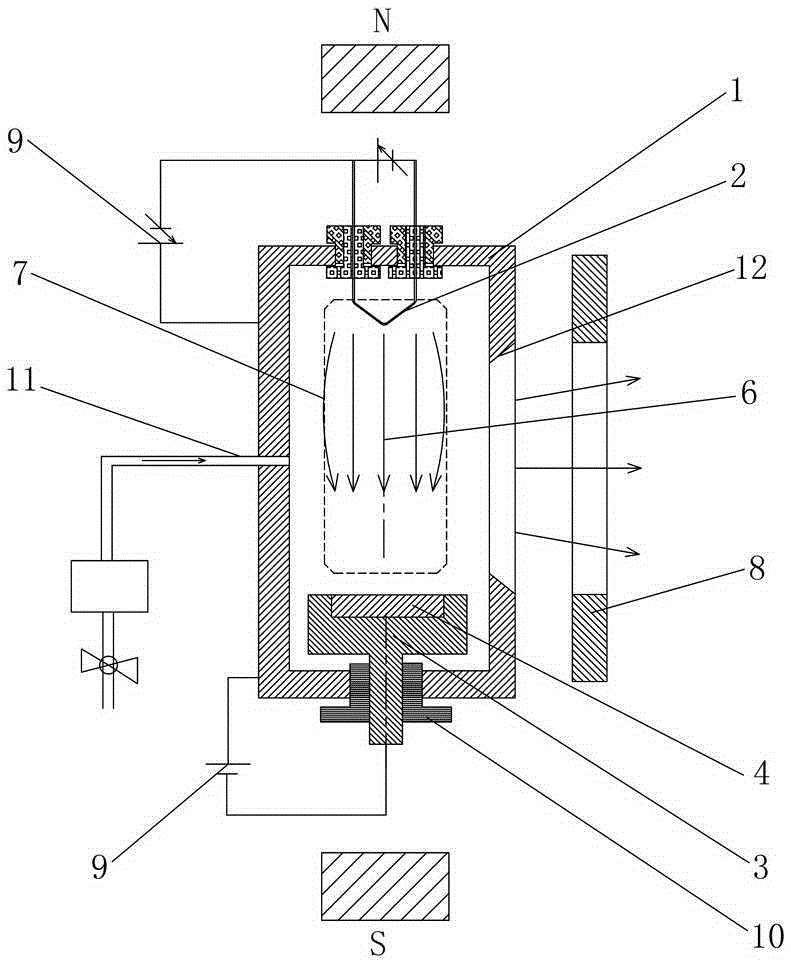

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

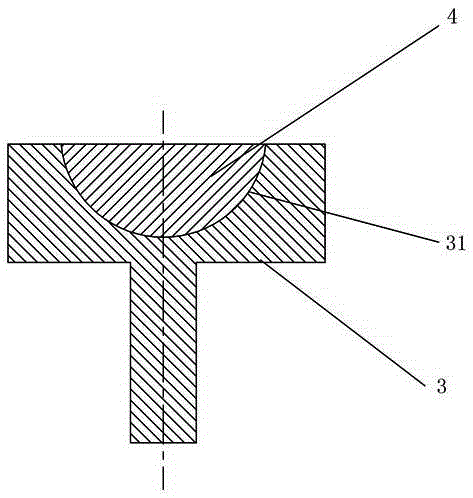

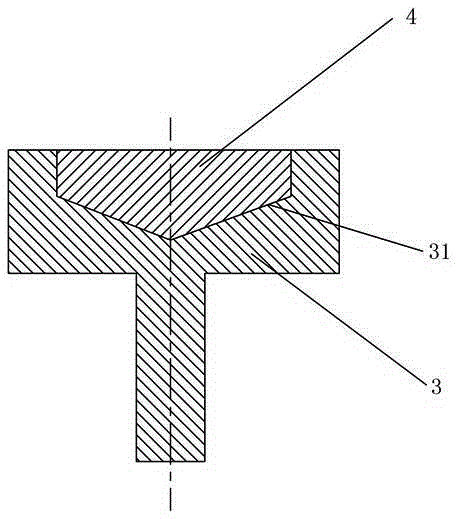

[0025] Figure 1 to Figure 2 It shows an embodiment of a reflective electrode structure of the present invention, including an opposing reflective electrode 3 made of a high melting point metal material and a sputtered part 4 made of a low melting point metal material. The front end of the opposing reflecting electrode 3 is provided with The installation groove 31 , the object to be sputtered 4 is embedded in the installation groove 31 , and is adjacent to the inner wall of the installation groove 31 . The sputtered part 4 is embedded in the installation groove 31, the area of the sputtered part 4 can be directly increased by increasing the size of the installation groove 31, and the ion content in the ion beam can be increased. This structure does not require other auxiliary parts to be installed, simplifying the The structure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com