Straight pipe product member oiling device

A technology for oiling devices and products, which is applied to devices and coatings that apply liquid to surfaces, and can solve problems such as large oil, low oiling efficiency, and deteriorating air in the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

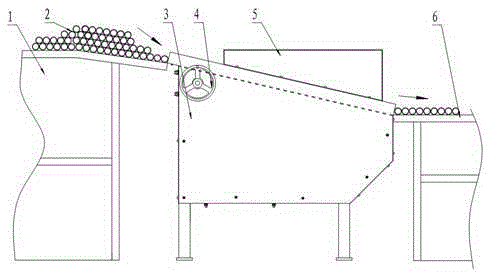

[0020] see figure 1 , the present invention includes a feeding platform 1, a material receiving platform 6 and an oiler. The straight pipe product parts 2 to be oiled are stacked on the feeding table, and then enter the oiler from the feeding table, and after oiling is completed, they are sent to the receiving table to enter the next process.

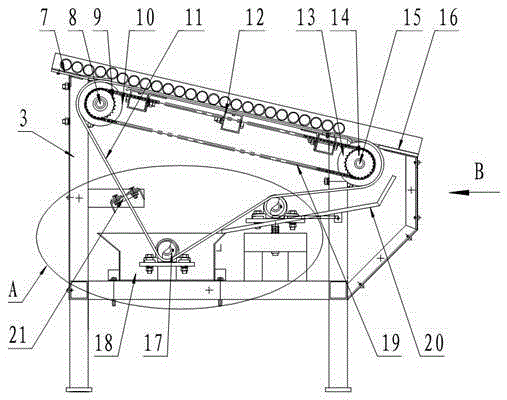

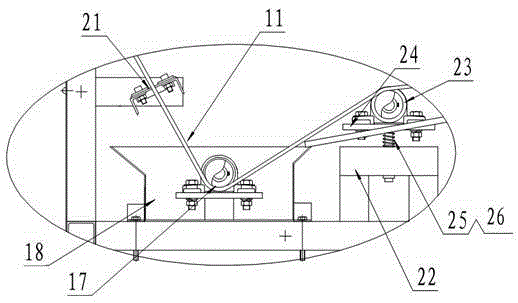

[0021] Oiler is the core technology of the present invention, see figure 2 , Figure 4 , the oiling machine is provided with an oiling rack 3, the upper part of the oiling rack is arranged obliquely, and the high end of the oiling rack is provided with a driving shaft 8, the driving shaft is connected with the hand wheel 4, and the driving shaft is equipped with a driving sprocket 9 and a driving roller 10. A driven shaft 15 is provided at the lower end of the oiling frame, and a driven sprocket 14 and a driven roller 13 are mounted on the driven shaft, and the driving sprocket and the driven wheel are connected through a chain 19 tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com