Production equipment and production process for novel multicolour wood-plastic composite material

A wood-plastic composite material and production equipment technology, which is applied in the field of wood-plastic composite material production equipment and production technology, can solve the problems of unstable color lines, high product scrap rate, deepening of the background color, etc., to solve the problem of color instability , rich texture, the effect of reducing the ability of plasticizing and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

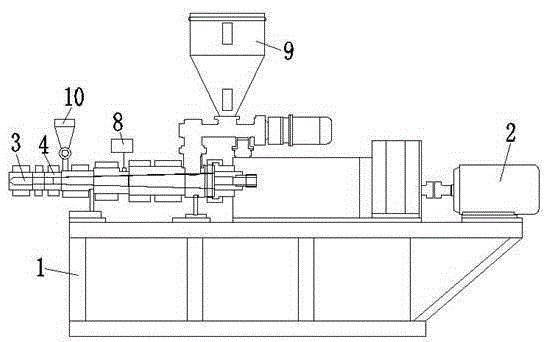

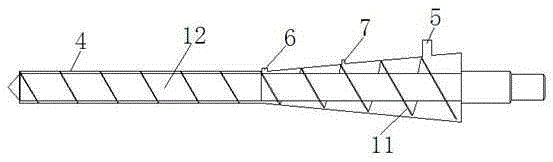

[0019] Such as figure 1 and figure 2 As shown, the production equipment of a novel multi-color wood-plastic composite material according to the present invention includes a frame 1, and a main motor 2 is arranged at one end above the frame 1, and the main motor 2 is connected with a screw rod 3 , the screw 3 is installed in the barrel 4, the barrel 4 is provided with a main feeding port 5 and a secondary feeding port 6, between the main feeding port 5 and the secondary feeding port 6 The barrel 4 is provided with a vacuum port 7, the vacuum port 7 is connected to the vacuum device 8, the main feeding port 5 is connected to the main feeding device 9, and the auxiliary feeding port 6 is connected to the auxiliary feeding device. The device 10 is connected, the screw rod 3 is composed of a conical section 11 and a cylindrical section 12, and the cylindrical section 12 is arranged at the shallow screw groove of the conical section 11; the main feeding port 5 and the auxiliary fe...

Embodiment 2

[0026] Such as figure 1 and figure 2 As shown, the production equipment of a novel multi-color wood-plastic composite material according to the present invention includes a frame 1, and a main motor 2 is arranged at one end above the frame 1, and the main motor 2 is connected with a screw rod 3 , the screw 3 is installed in the barrel 4, the barrel 4 is provided with a main feeding port 5 and a secondary feeding port 6, between the main feeding port 5 and the secondary feeding port 6 The barrel 4 is provided with a vacuum port 7, the vacuum port 7 is connected to the vacuum device 8, the main feeding port 5 is connected to the main feeding device 9, and the auxiliary feeding port 6 is connected to the auxiliary feeding device. The device 10 is connected, the screw rod 3 is composed of a conical section 11 and a cylindrical section 12, and the cylindrical section 12 is arranged at the shallow screw groove of the conical section 11; the main feeding port 5 and the auxiliary fe...

Embodiment 3

[0033] Such as figure 1 and figure 2 As shown, the production equipment of a novel multi-color wood-plastic composite material according to the present invention includes a frame 1, and a main motor 2 is arranged at one end above the frame 1, and the main motor 2 is connected with a screw rod 3 , the screw 3 is installed in the barrel 4, the barrel 4 is provided with a main feeding port 5 and a secondary feeding port 6, between the main feeding port 5 and the secondary feeding port 6 The barrel 4 is provided with a vacuum port 7, the vacuum port 7 is connected to the vacuum device 8, the main feeding port 5 is connected to the main feeding device 9, and the auxiliary feeding port 6 is connected to the auxiliary feeding device. The device 10 is connected, the screw rod 3 is composed of a conical section 11 and a cylindrical section 12, and the cylindrical section 12 is arranged at the shallow screw groove of the conical section 11; the main feeding port 5 and the auxiliary fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com