Apparatus for collecting and reprocessing steam in steam packing machine

A recycling processing and packaging machine technology, applied in the direction of wrapping paper shrinkage, packaging, wrapping paper, etc., can solve the problems of increased manufacturing cost, larger installation space, larger scale, etc., and achieve the effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the preferred embodiment of the present invention is described in detail with reference to the accompanying drawings, but this is only to make it easy for those with basic knowledge to implement the present invention in detail in the technical field to which the present invention belongs, and the technical thought and scope of the present invention are not limited thereby .

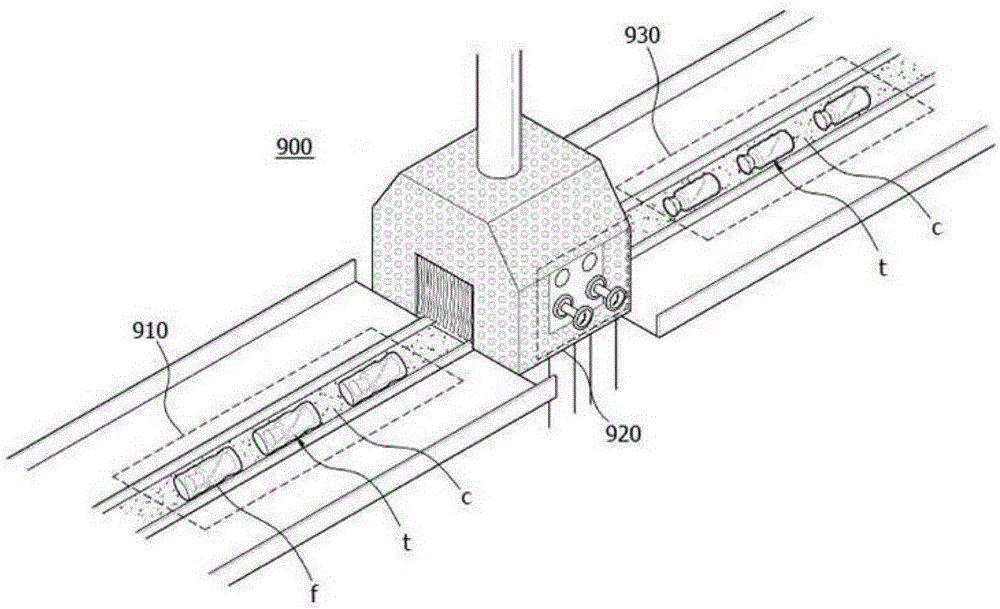

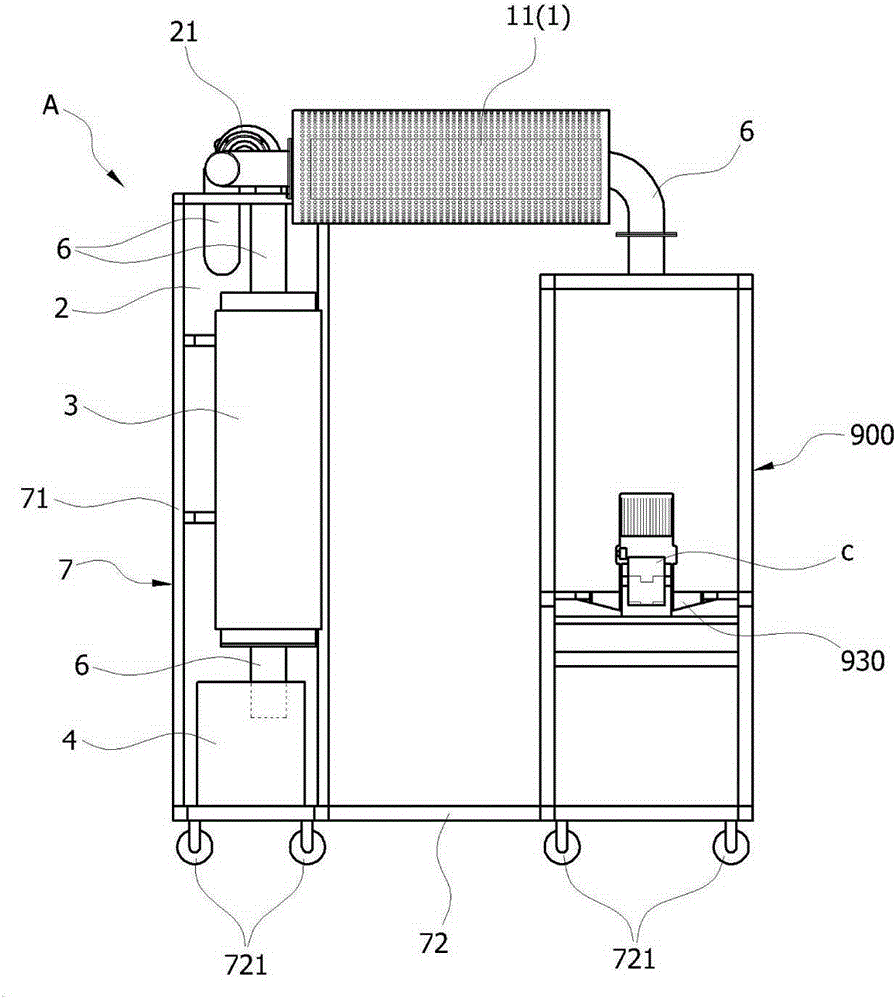

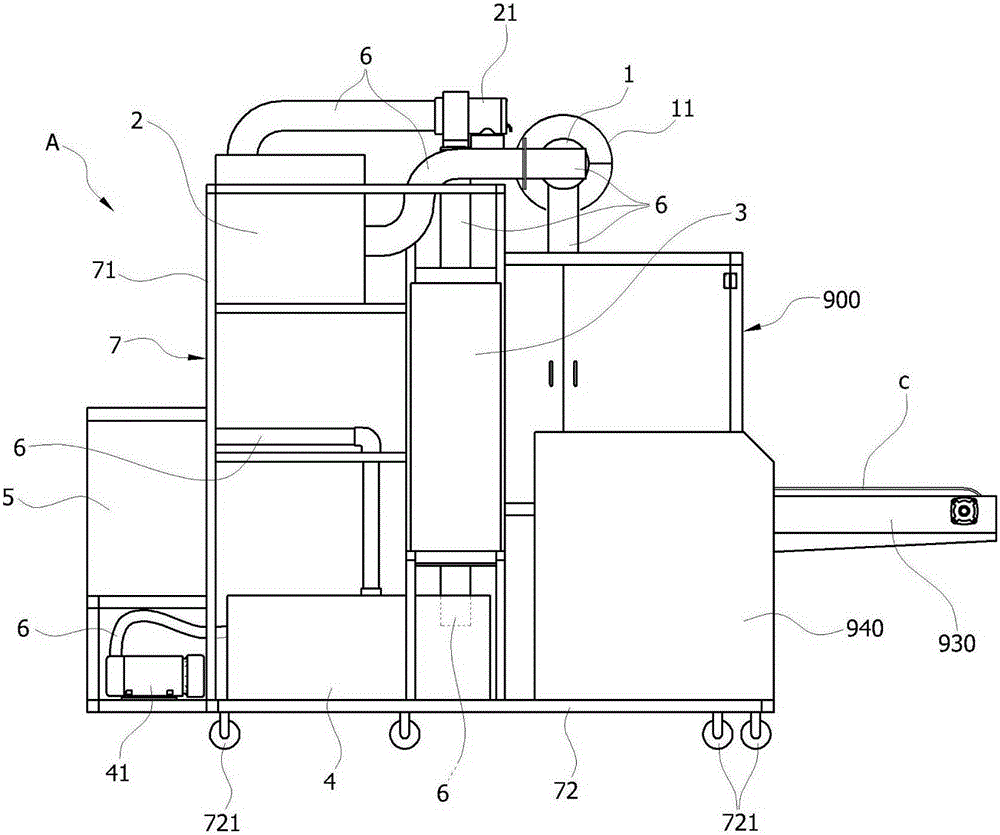

[0038] image 3 is a diagram showing the exterior of a steam packaging machine with a steam recovery device according to an embodiment of the present invention, Figure 4 It is a front view showing the steam recovery processing device of the steam packaging machine according to the embodiment of the present invention.

[0039] The steam packaging machine 200 with the steam recovery treatment device 100 according to the embodiment of the present invention is as image 3As shown, a steam heating part 300 is arranged in the frame 210, which heats the surface of the product container 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com