Oil-water separation device preventing crude oil storage tank from deflagration

A technology of oil-water separation device and crude oil storage tank, which is applied in the fields of basic materials and mechanics, can solve problems such as explosions and economic losses, and achieve the effects of strong safety, low cost, and easy installation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

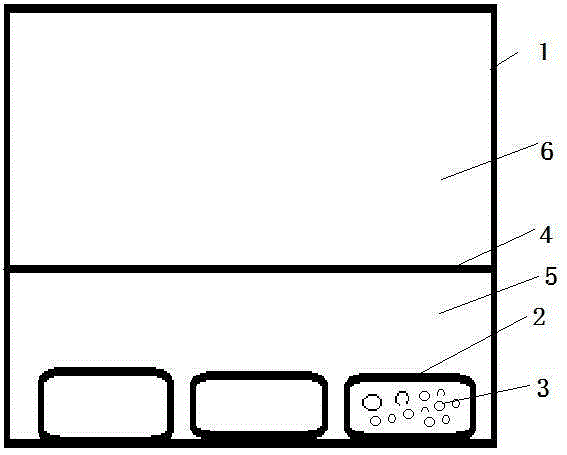

[0013] like figure 1 As shown, nine microbead releasers 2 are installed at the bottom of the storage tank 1 . When the crude oil is injected into the tank body 1 for a certain period of time, an oil-water interface 4 will gradually be formed. When the microbead releaser 2 receives the order, it releases the ceramic microbeads 3 stored in it, and when the microbeads 3 slowly rise to the oil-water interface 4 in the water layer 5, they encounter crude oil 6 with a higher viscosity, It will float up very slowly or even stop, thus forming a dense heat insulation layer at the interface of oil and water.

[0014] The crude oil tank 1 is a steel tank for storing crude oil, and its volume is generally 100,000m 3 .

[0015] The microbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com