Rotary piston pump for continuously filling and conveying emulsion explosives

A rotary piston pump and emulsified explosive technology, which is applied to explosives, explosives processing equipment, pumps, etc., can solve problems such as damage, reduced speed, production capacity, and large axial load, and achieve the effects of ensuring performance, safe transportation, and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

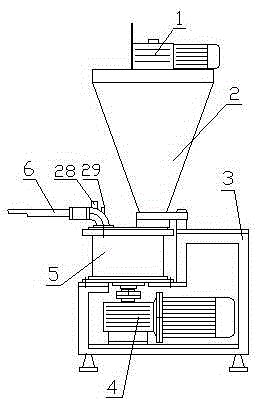

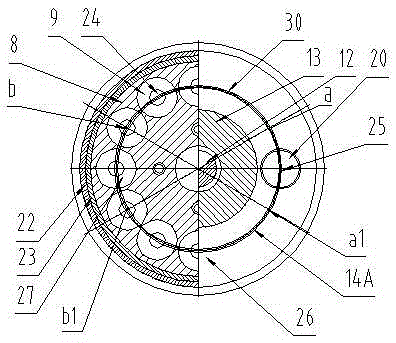

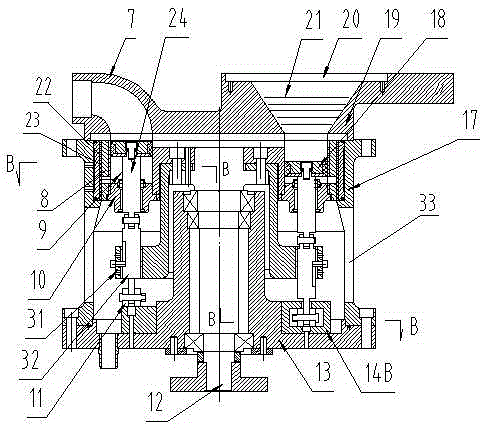

[0025] exist figure 1 , figure 2 and image 3 The piston rotary pump for continuously filling and conveying emulsion explosives shown has a single-layer guide rail and spring structure, which includes a frame 3, a feeding hopper 2, a feeder 1, a pump body 5, a rotating power mechanism 4, and a discharge nozzle 6. The pump body is fixedly installed on the frame through the base 13 thereon; the feed hopper 2 is fixedly connected to the feeding interface 20 of the pump body, and can communicate with the cylinder hole in the pump body, and the feeder is set On the feed hopper, the discharge nozzle 6 is fixedly connected with the discharge interface 7 on the pump body and communicates with the cylinder hole 9 rotated to the left end position of the horizontal centerline in the pump body; the rotary power mechanism 4 is connected to the pump body The main shaft 12 on the 5 is connected to provide rotational power for the main shaft; in order to facilitate precise control and safe...

Embodiment 2

[0027] Such as figure 1 , Figure 4 and Figure 5 The shown a kind of emulsified explosive continuous loading and conveying piston rotary pump is a double-layer guide rail structure, which includes a frame 3, a feed hopper 2, a feeder 1, a pump body 5, a rotary power mechanism 4, and a discharge nozzle 6. The pump body is fixedly installed on the frame through the base 13 thereon; the feed hopper 2 is fixedly connected to the feeding interface 20 of the pump body, and can communicate with the cylinder hole in the pump body, and the feeder is arranged at the inlet On the hopper, the discharge nozzle 6 is fixedly connected to the discharge interface 7 on the pump body and communicates with the cylinder hole 9 in the pump body that rotates to the left end of the horizontal center line; the rotating power mechanism is connected to the main shaft on the pump body 12 connected to provide rotational power for the main shaft; in order to facilitate precise control and safe operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com