Cable type electrohydraulic control pipe cutting tool

An electro-hydraulic control and pipe cutting technology, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of low success rate of failure recovery, small cutting range margin, difficult cutting operation, etc., and achieve anchorage output force and Controllable, large cutting range margin, and large power-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

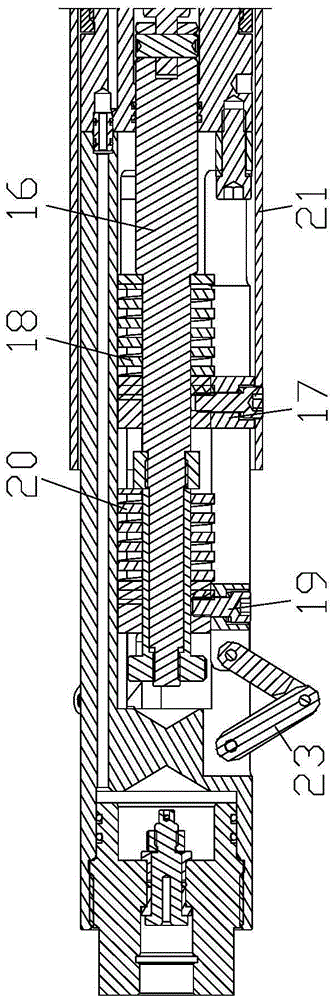

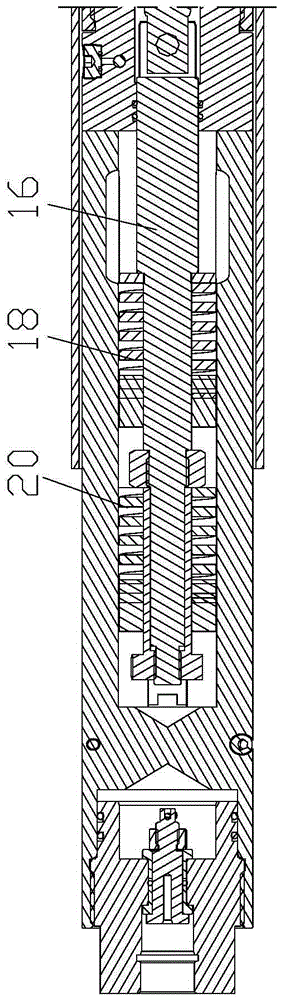

[0021] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

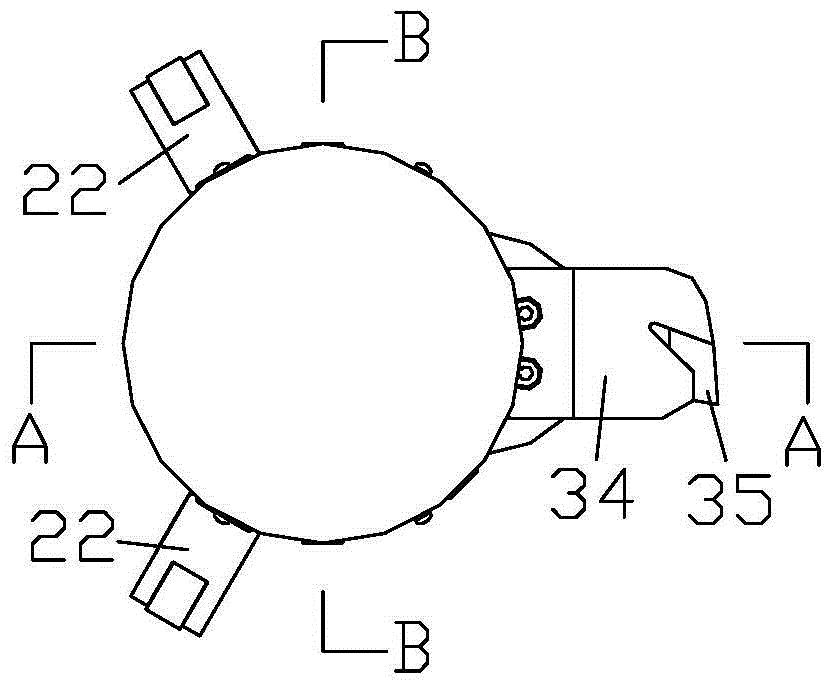

[0022] Such as Figure 1-Figure 7 As shown, the cable-type electro-hydraulic control pipe cutting tool related to the present invention includes an anchor module and a cutting module, the anchor module is arranged at the rear, and the cutting module is arranged at the front, and the anchor module is composed of an electro-hydraulic oil source device, The environmental pressure balance device, the electro-hydraulic drive control device and the anchoring actuator are composed of the electro-hydraulic oil source device consisting of an anchoring motor 1, an anchoring motor reducer 2 and a hydraulic pump 3, and the anchoring motor 1 passes through the anchoring motor reducer 2 Connected with the hydraulic pump 3, the environmental pressure balance device is composed of the environmental balance piston joint 4, the anchor filter screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com