Method for preparing metallic oxide hollow nano-sphere

A technology of hollow nanometer and oxide, which is applied in the direction of granulating raw materials, chemical instruments and methods, microsphere preparation, etc., can solve the problems of uneven shape, poor controllability and repeatability, etc., and achieve easy removal, The size and thickness are controllable and the output is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Add 60 mg of silica spheres to 50 ml of 0.5 mol / L sodium chloride aqueous solution, and sonicate for 1 hour, then add 20 ml of 0.02 mol / L positively charged polyallylamine hydrochloride solution, and Stirring for 0.5 hour, polyallylamine hydrochloride is coated on the surface of the silica ball, and centrifugally cleaned with deionized water;

[0020] 2) Add 20 milliliters of 0.04 mol / liter negatively charged sodium polystyrene sulfonate solution, and stir for 0.5 hours, then centrifuge and wash with deionized water;

[0021] 3) Add 20 ml of 0.02 mol / L polyallylamine hydrochloride solution, and stir for 0.5 hour, then centrifuge and wash with deionized water;

[0022] 4) redisperse the product obtained in step 3) in 100 milliliters of deionized water, and add 0.5 mmol of tin chloride;

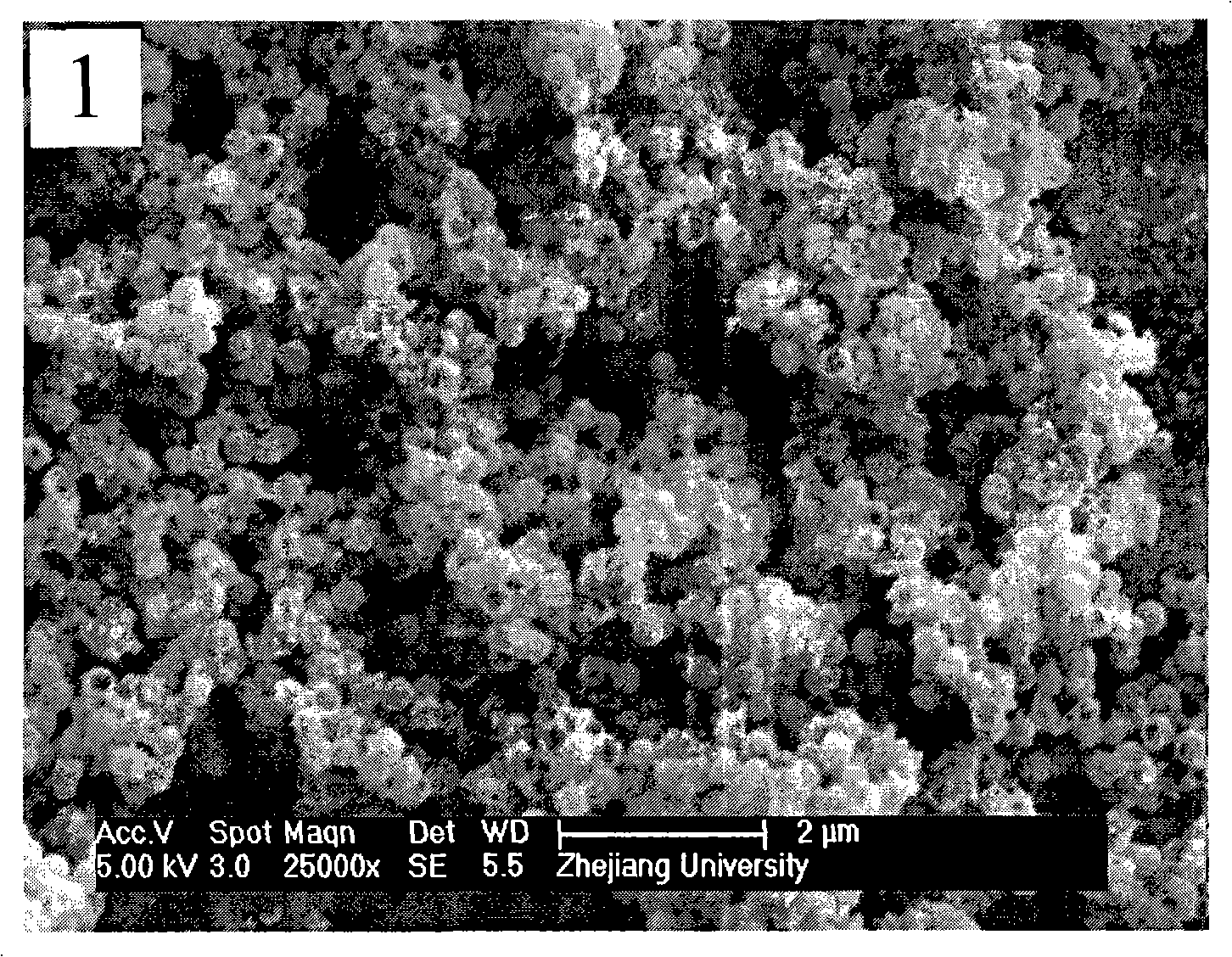

[0023] 5) Add 20 milliliters of 0.1 mol / liter sodium borohydride aqueous solution dropwise to the above solution, then centrifuge and dry, heat-treat under oxygen at 500°C for 3 hour...

Embodiment 2

[0026] 1) Add 60 mg of silicon dioxide spheres to 20 ml of 0.5 mol / L sodium chloride aqueous solution, and sonicate for 1 hour, then add 20 ml of 4 mol / L polyallylamine hydrochloride solution, and stir for 0.5 hour, Coating polyallylamine hydrochloride on the surface of silica balls, and centrifugally cleaning with deionized water;

[0027] 2) Add 20 ml of 0.02 mol / L sodium polystyrene sulfonate solution, and stir for 0.5 hour, then centrifuge and wash with deionized water;

[0028] 3) Add 20 ml of 0.4 mol / L polyallylamine hydrochloride solution, and stir for 0.5 hour, then centrifuge and wash with deionized water;

[0029] 4) redisperse the product obtained in step 3) in 100 milliliters of deionized water, and add 5 mmoles of tin chloride;

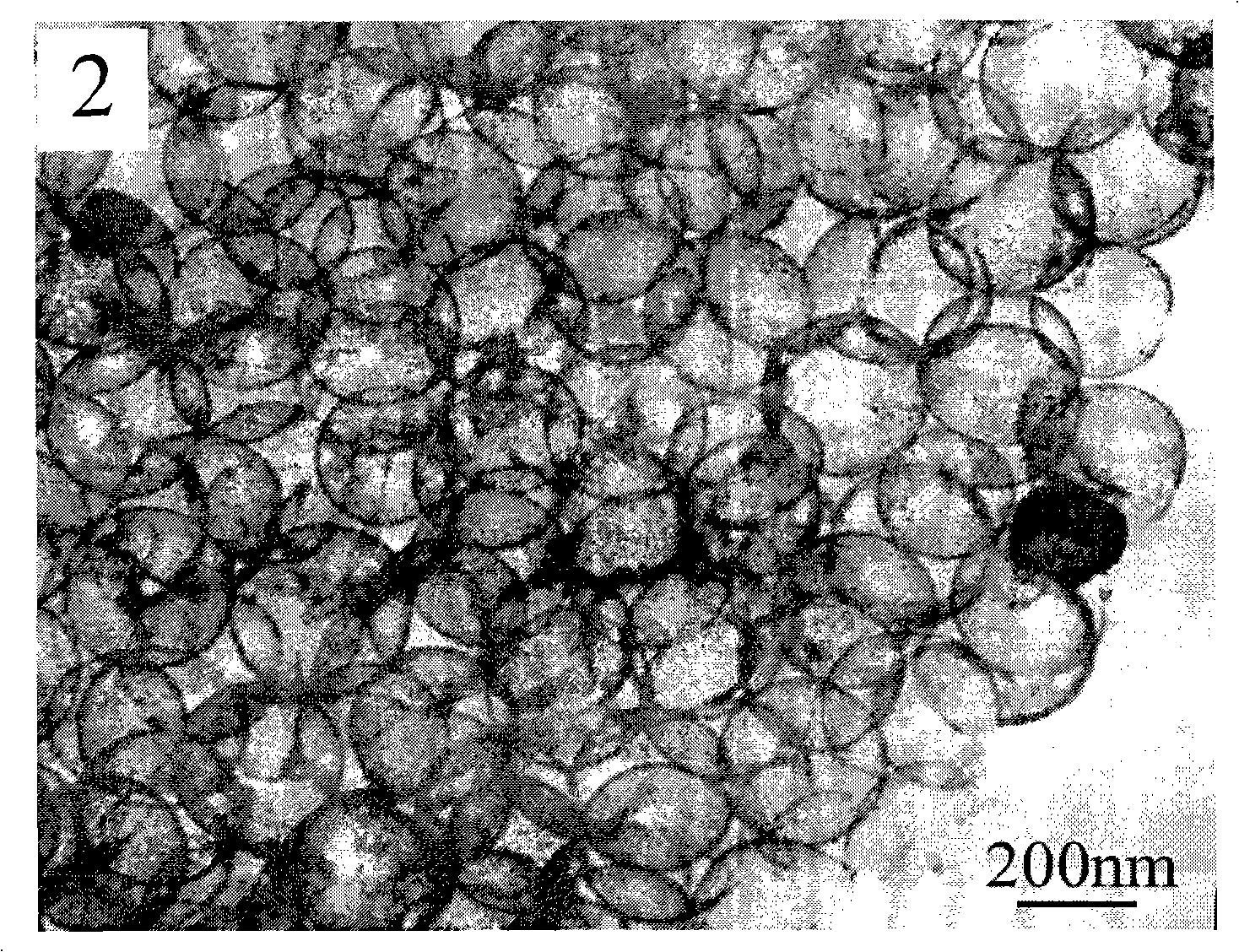

[0030] (5) Add dropwise 50 milliliters of 0.1 mol / liter sodium borohydride aqueous solution in the above solution, then centrifuge and dry, heat-treat for 5 hours under 500 DEG C of oxygen, then soak in 1% hydrofluoric acid solution of m...

Embodiment 3

[0032] 1) Add 120 mg of silicon dioxide spheres to 200 ml of 0.5 mol / L sodium chloride aqueous solution, and sonicate for 1 hour, then add 20 ml of 0.08 mol / L polyallylamine hydrochloride solution, and stir for 0.5 hour, Coating polyallylamine hydrochloride on the surface of silica balls, and centrifugally cleaning with deionized water;

[0033] 2) Add 20 milliliters of 0.04 mol / liter sodium polystyrene sulfonate solution, and stir for 0.5 hours, then centrifuge and wash with deionized water;

[0034] 3) Add 20 ml of 0.08 mol / L polyallylamine hydrochloride solution, and stir for 0.5 hour, then centrifuge and wash with deionized water;

[0035] 4) redisperse the product obtained in step 3) in 100 ml of deionized water, and add 1 mmol of indium chloride;

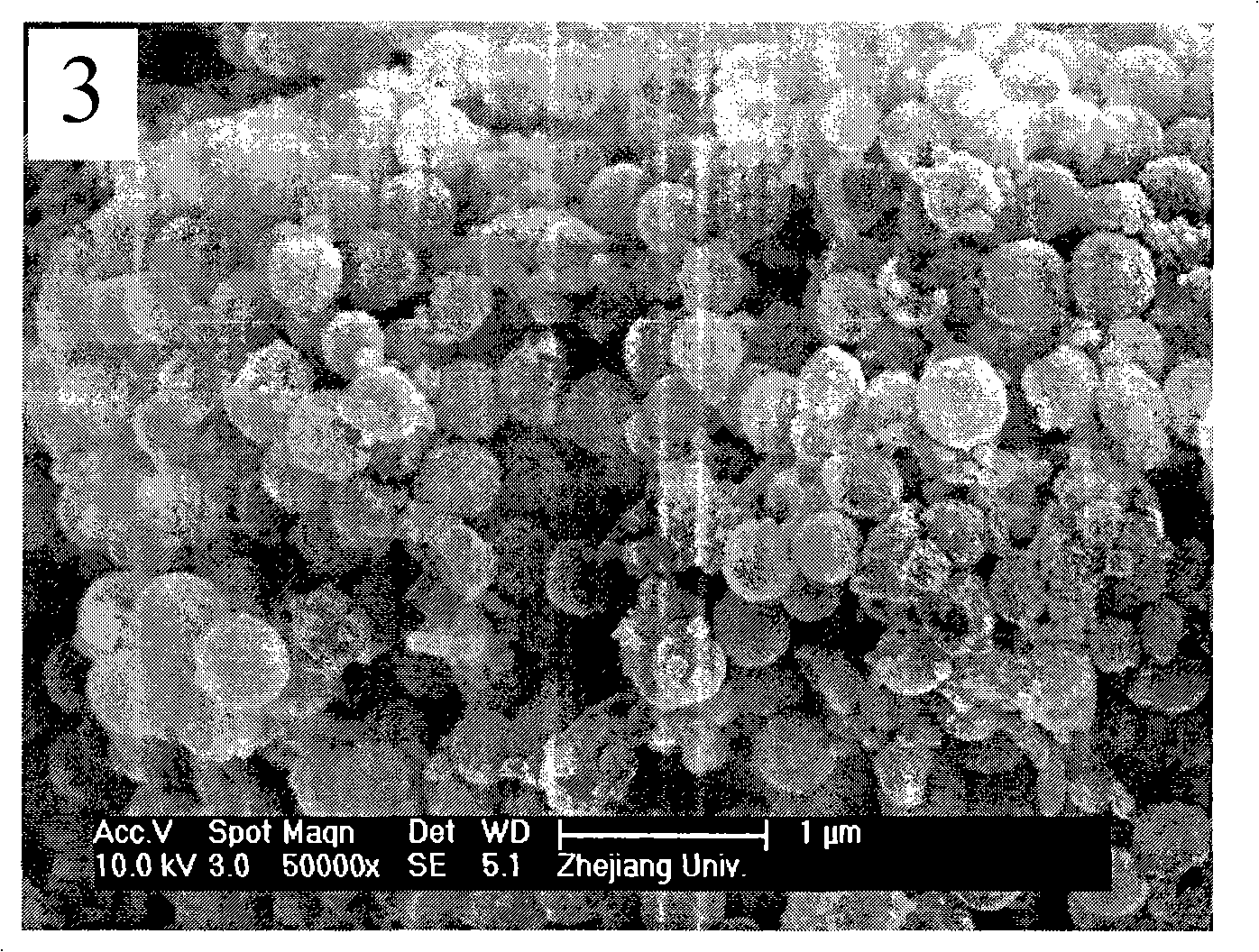

[0036] 5) Add dropwise 500 milliliters of 0.1 mol / liter sodium borohydride aqueous solution in the above solution, then centrifuge and dry, heat-treat under oxygen at 600°C for 3 hours, and then soak in a hydrofluoric acid so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com