Power output system and output method for agricultural machinery

A technology for power output and agricultural machinery, which is applied in mechanical equipment, transmission devices, fluid transmission devices, etc., can solve the problems of high working pressure, limited engine speed, and high cost of high pressure in the walking hydraulic system, so as to reduce working pressure and increase input Speed, the effect of increasing the output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in combination with specific embodiments.

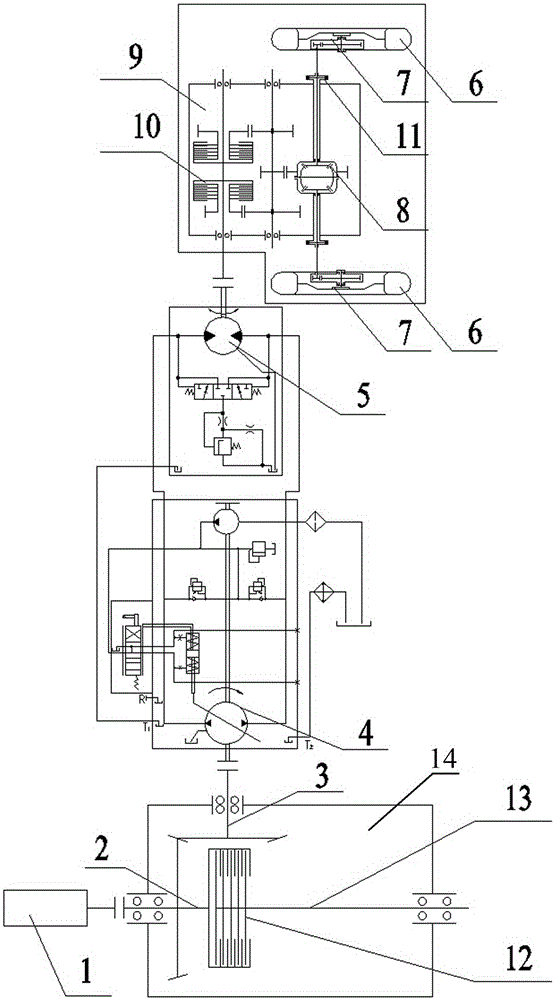

[0019] As shown in the figure: a power output system for agricultural machinery, the system includes an engine 1, a power output mechanism 14 and a walking system, the engine 1 outputs power to the walking system and the working system through the power output mechanism 14, and the power output mechanism 14 Including power input shaft 2, bevel gear, main clutch 12, walking system power output shaft 3 and working system power output shaft 13, power output mechanism 14 outputs power to the working system through the main clutch 12, and at the same time outputs power to the walking system through bevel gear transmission system, the main clutch 12 and the bevel gear transmission are included in the power take-off mechanism 14 housings, the power output shaft 13 of the working system and the power output shaft 3 of the walking system are all output through the 14 housings of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com