Multiple-cavity weighting-method water-vapor permeability testing system and testing method

A technology of testing system and weighing method, which is applied in material weighing, measuring device, permeability/surface area analysis, etc., can solve the problems affecting the testing accuracy, fewer testing stations, and long testing time, so as to improve testing efficiency, Effects of eliminating weighing errors and improving operational accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

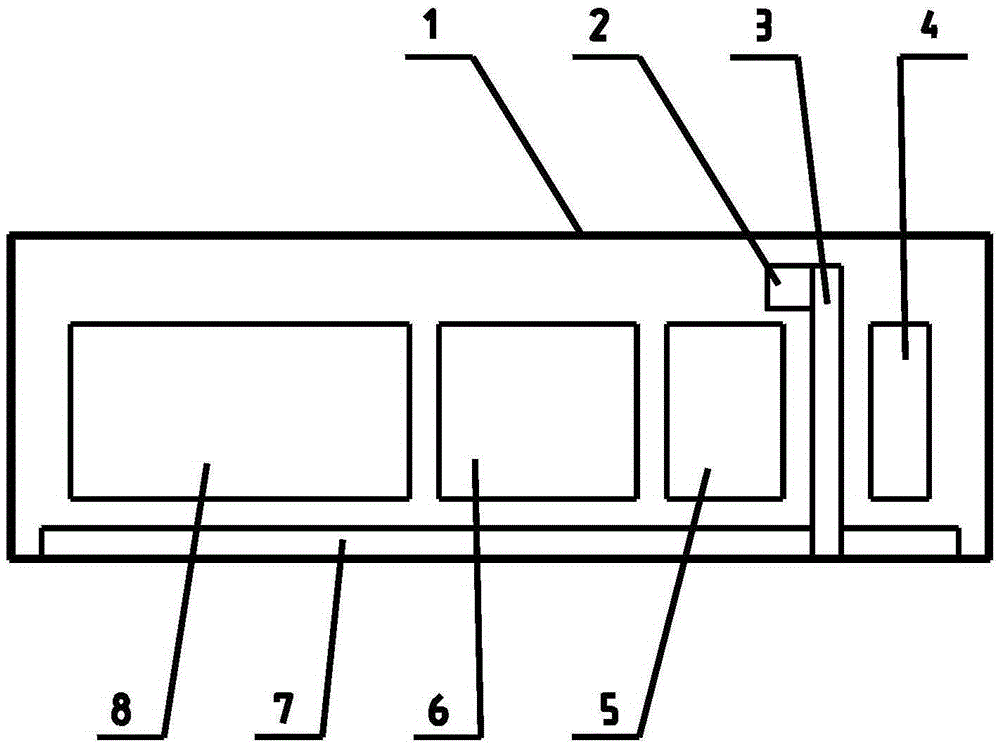

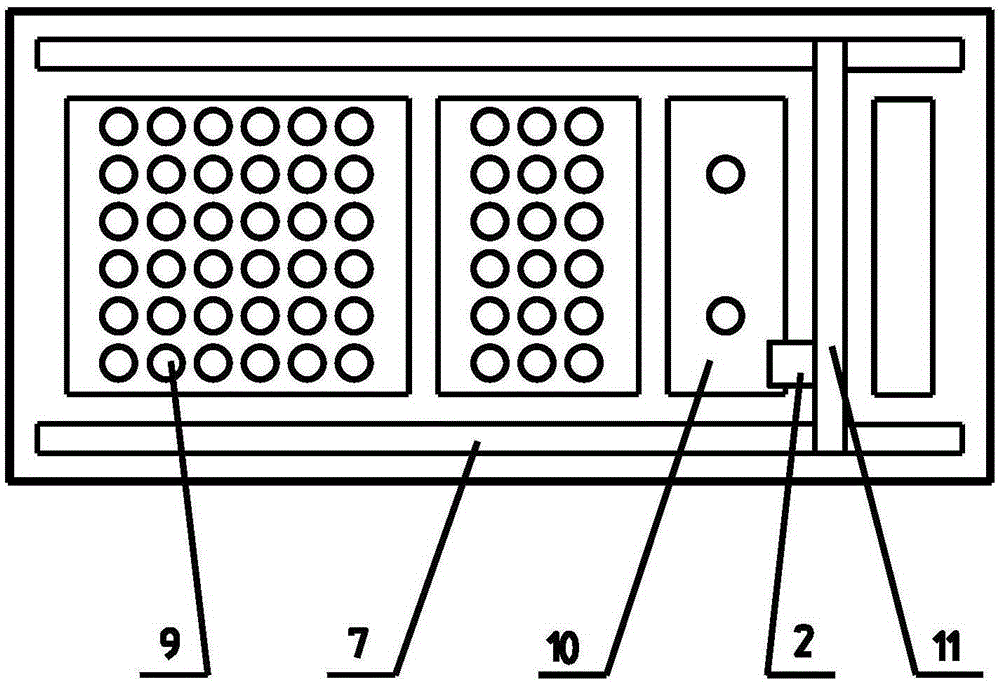

[0036] Such as Figure 1-Figure 2 As shown, the multi-chamber gravimetric moisture permeability test system includes a frame 1, a test chamber 8, a buffer chamber 6, a weighing chamber 5, and a moving device for a manipulator. The frame 1 is a framework for installing various components. A test cup 9 is provided in the test chamber 8, a weighing element 10 is provided in the weighing chamber 5, a manipulator moving device is provided on the frame 1, and a sample is provided in the test cup 9. The manipulator moving device includes an X-axis moving device 7, a Y-axis moving device 11, and a Z-axis moving device 3. The manipulator 2 is installed on the manipulator moving device. The manipulator moving device can move the test cup 9 along the XYZ axis, and the manipulator 2 can move freely in any direction. Rotating, the gripping range of the manipulator 2 covers the entire range of the test chamber 8 , the buffer chamber 6 and the weighing chamber 5 . After the test cup 9 reach...

Embodiment 2

[0044] Replace the manipulator in Example 1 with a vacuum chuck, and drive the vacuum chuck to move the test cup through the X-axis moving device, Y-axis moving device and Z-axis moving device to complete the entire experiment process. Other structures are the same as in Example 1.

Embodiment 3

[0046] Replace the specific form of the manipulator moving device in Embodiment 1 with a turntable structure, install a turntable that rotates in the horizontal direction at the middle of the bottom of the frame, the upper part of the turntable that turns in the horizontal direction is connected with the turntable that turns in the vertical direction, and the turntable that turns in the vertical direction The turntable is connected with the connecting rod, and the manipulator is installed at the end of the connecting rod; the turntable that rotates in the horizontal direction and the turntable that rotates in the vertical direction are connected with the drive device, and driven by the drive device, the turntable that rotates in the vertical direction drives the manipulator to move up and down to grab different The test cup in the test chamber, the turntable that rotates in the horizontal direction drives the manipulator to move horizontally, and moves the test cup from the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com